Small Laser Displacement SensorsCD33 Series

Half-palm size. Ideal for built-in use with smaller machines.

- Specular reflection types have been added to the line up

- Control units for Mitsubishi Electric PLC are available

Specular reflection types

for measurements of specular and transparent objects.

Specular reflection types have been added to the line up to enable the measurement of transparent objects such as glass workpiece, as well as specular objects such as wafers, etc. This means that transparent and specular objects that were diffi cult to measure using diffuse-refl ective types can now be measured with stability.

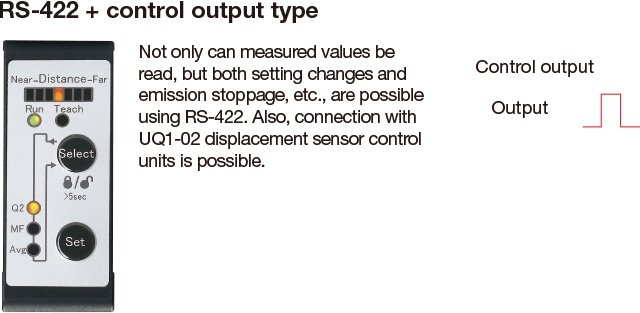

Thickness measurements also possible

-

When using a specular reflection type to measure transparent objects, not only surface displacement, but also thickness can be measured. As shown below, when the laser light is emitted at an angle, light reflected from both the front and rear surfaces of the glass are received by receiver element. Thickness measurements are possible by measuring between the peaks of these reflected light forms.

-

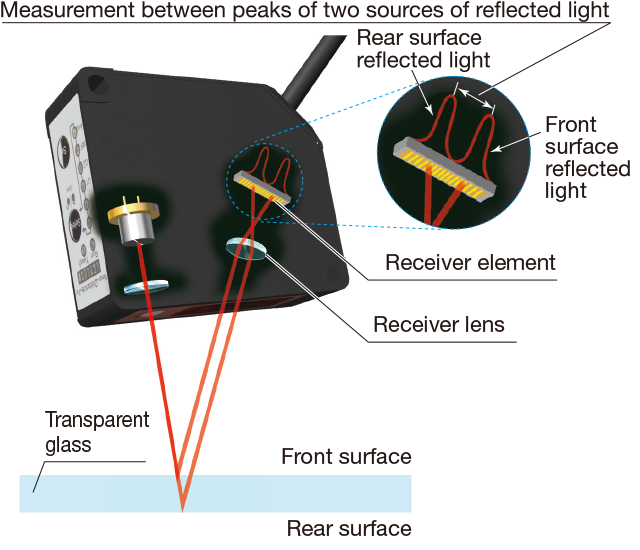

Direct connection to Mitsubishi Electric PLCs

-

The UQ1-02 displacement sensor control unit that can be connected to the Mitsubishi Electric MELSEC-Q series!

In addition to the fact that absolutely no communications settings are necessary, by using the specialized UQ1 Navigator software it is possible for any one to perform set up easily in a short period of time.

*Can be used with the RS-422 type of the CD33 series -

Original built-in technology

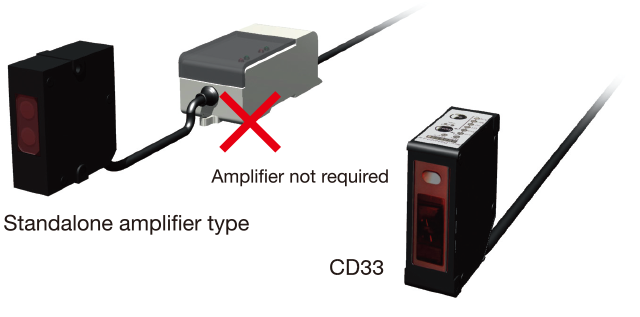

Lightweight with a built-in amplifier!

-

An amplifier and all control functions are integrated into the sensor head. You don't have to worry about space for installing to control panels.

It also features a light weight of approx. 65 g, enabling it to be installed to movable parts such as chip mounters or robot arms. -

Uses sub-pixel processing and automatic sensitivity switching function

Pursuit of the limits in terms of accuracy and measurement stability!

-

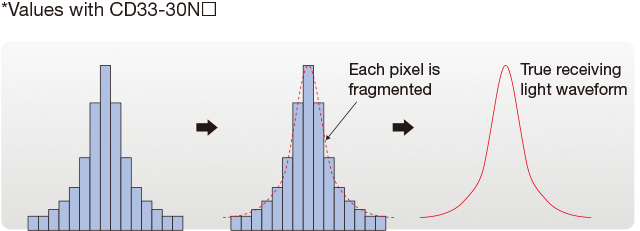

Sub-pixel processing that recognizes true waveforms

Sub-pixel processing is employed that performs recognition by fragmenting each C-MOS element pixel. By accurately detecting the true receiving light waveform, it is possible to correctly measure the distance to a workpiece. Repeat accuracy is also 2 μm* and support is provided for high-accuracy displacement measurement.

*Values with CD33-30N☐

-

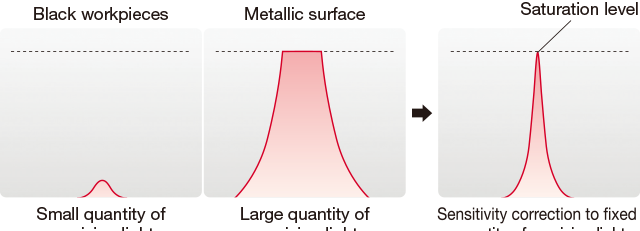

High-accuracy sensitivity switching function effective against influence caused by workpiece material and color

The opening degree of the shutter is switched automatically in accordance with the reflection rate of the workpiece. By controlling the receiving light quantity and constantly correcting to the optimal sensitivity, we have succeeded in keeping errors caused by color and materials to an absolute minimum.

Low cost version that eliminates unnecessary circuits

Realizing a high level of cost performance with a wide output-based lineup

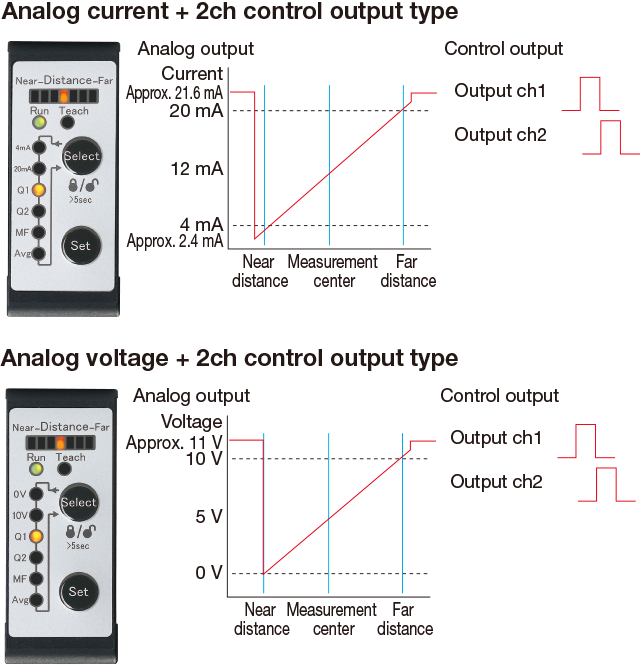

While many of our competitors’ displacement sensors have multiple types of measured value outputs, customers can make selections from “analog current + 2ch control output type”, “analog voltage + 2ch control output type”, “RS-422 + control output type”, based on the input device used. Also, by eliminating unnecessary circuits, a highest-in-class level of cost performance has been realized. These laser displacement sensors are highly-accurate, low in cost, and easy to introduce.