Fiber-Optic CablesNF Series Liquid/Water detection type

Fiber-Optic Cables for detecting liquid

- Lineup of liquid level detection and water detection devices

- A liquid accumulation prevention structure is used for all liquid level contact type models NF-DF07, NF-TF01, NF-DA52, NF-DA53:

End of sales by August 2025

Mounting method

NF-DF04/-DF05

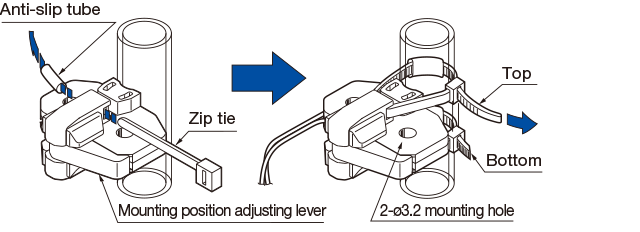

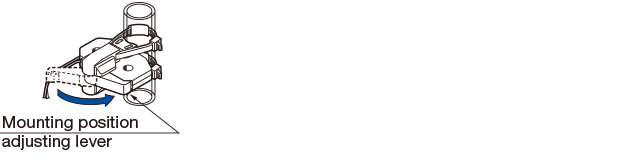

・Use the included zip ties and anti-slip tubes for mounting as shown in the diagram below. When mounting the Fiber-Optic Cables, make sure that the mounting position adjusting lever is in the closed position as shown in the diagram below. Also, use two zip ties on the upper and lower part to attach it securely, and cut off the any part of the zip ties that stick out.

・When additional zip ties are necessary, please use zip ties with a thickness 2.5 mm or smaller as shown by in the diagram below.

・M3 screws, plain washers and spring washers must be used when using the mounting holes. (M3 screws, plain washers and spring washers are not included with this product.)

Adjusting the positions of pipe-mounted liquid level detection Fiber-Optic Cables

・The attachment position can be easily readjusted when using zip ties to mount this product.

Adjustment method

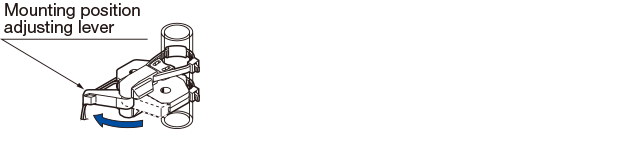

1. Pull the mounting position adjusting lever open in the direction of the arrow.

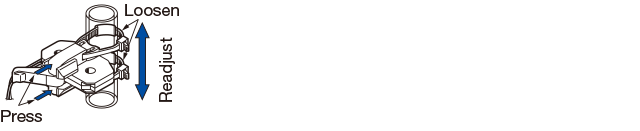

2. Push the moveable part in the direction of the arrow to loosen the zip tie, and readjust the mounting position.

3. Close the mounting position adjusting lever in the direction of the arrow to return it to its original position.

Note 1: Sensitivity settings must be reconfigured after readjusting the mounting position.

Note 2: The positioning lever is for readjusting the mounting position on this device, not for tightening the zip ties. Tightening the zip ties while the mounting position adjusting lever is open and then closing the mounting position adjusting lever will damage the fibers.

Usage notes

Liquid level detection type Fiber-Optic Cables

・When cutting the protective tubes, take care not to damage the fiber sheath.

・Amounts of light may decrease during extended periods of usage under conditions with high heat or humidity.

・Water droplets adhered to the window will influence detection performance. Avoid use in areas where direct contact with water could be made. Also pay sufficient attention to any condensation that has formed on the pipe exterior.

NF-DF04/-DF05

・Be aware that some low-transparency liquids and highly viscous liquids with stability may not be able detect.

・Incomplete pipe mounting may have a severe influenced on detection performance. Use the included anti-slip tubes and install the detecting part to the pipe so it does not move.

・The NF-DF04/-DF05 cannot properly detect through opaque pipes.

・Attach the detecting part so it is secured to the pipe. Failure to do so will result in malfunction.

・Because the NF-DF04/-DF05 does not have a water resistant or chemical resistant structure, avoid areas where water or chemicals could come in contact.

・Because adherence of water droplets on the window of the NF-DF04/-DF05 will affect detection, pay sufficient attention to any condensation that has formed on the pipe exterior. Also be aware that water droplets formed on the inside of pipes, as well as air bubbles adhered on the inside will affect detection.

NF-DW02

・Clean NF-DW02 by wiping away all liquids that have adhered to the head and mounting bracket using a soft cloth. Also pay sufficient attention to any condensation that has formed on the detecting part.

・If the tips of the fibers are too short, be aware that the correct amounts of light may not be taken in, resulting in unstable detection.

・When installing NF-DW02, be sure to use the special mounting bracket as a countermeasure to human error (improper installation, etc.) Failure to use the special bracket may result in unstable detection. However, if using a PVC mounting bracket on the black matte part of the housing, sensing of human error (improper installation) may not be possible. Please confirm before using.

・When cutting the protective tubes, take care not to damage the fiber sheath.

・Perform sensitivity settings for the NF-DW02 only after any liquids have been removed, the head has been mounted to the special mounting bracket, and the fiber has been attached to the Fiber-Optic Cable. After performing the sensitivity adjustment, changing the fiber connection or installation will result in changes in the light detection volume, causing unstable detection. Changing fiber connections or installation during cleaning, etc., will have the same results. In such cases, perform amplifier sensitivity adjustments again.

・Amounts of light may decrease during extended periods of usage under conditions with high heat or humidity.

・Be aware that instability may occur in which a long period is necessary before detection stability can be regained if liquids incompatible with the materials of which the NF-DW02 head part is made (PFA) cause air bubbles to flood the detecting part. Always confirm the liquid to be detected before use.

・When cleaning the NF-DW02 confirm that the mounting bracket shows no scratching, contamination, or deformities.

・Water droplets adhered to the window will influence detection performance. Avoid use in areas where direct contact with water could be made. Also pay sufficient attention to any condensation that has formed on the pipe exterior.