IO-Link MasterUR Series

Highly functional IO-Link Master for various industrial Ethernet

- First in industry* Mixed connection of digital Sink(NPN) / Source(PNP) I/O devices is realized with one unit

- Largest no. in industry* 16 channels

- Fastest in industry* Realized the minimum cycle time of 0.3 ms

NEW MODELS

e-CON type, UR-ME/EE16DT added to lineup

*Regarding IO-Link Master, surveyed by OPTEX FA in December, 2023.

Firmware download page for IO-Link Master UR Series

Firmware updates provide new features and improvements to existing functions.

Download List

Firmware corresponding to each version can be downloaded.

UR-MS16DT, UR-ME16DT

| Firmware version |

Functional improvements |

Connection procedure |

Download | |

|---|---|---|---|---|

| 1.06xxxx01 | - | - | CC-Link IE Field |

|

| CC-Link IE TSN |

||||

| 1.10xxxxxx |

- | - | CC-Link IE Field |

|

| Supports firmware version upgrade via direct LAN connection with a PC. | The direct connection may not be supported in all environments or under certain conditions. Refer to [Firmware Update Procedure Manual] for detail instructions. |

CC-Link IE TSN |

||

| 1.21xx40xx (March 2025) |

Expanded counter function ・Expanded to 16 channels |

This update includes changes to the settings menu. The former menu "M15. Encoder input" will be changed to "M18. Pulse input". Configuration settings from the previous version will be automatically and seamlessly transferred to the updated menu item. |

CC-Link IE Field |

Download |

| CC-Link IE TSN |

Download |

UR-ES16DT, UR-EE16DT

| Firmware version |

Functional improvements |

Connection procedure |

Download | |

|---|---|---|---|---|

| 1.05xxxx01 | - | Do not perform a downgrade to this version on UR-EE units with Lot No. 2440L or later. | - | Download |

| 1.10xx40xx |

Expanded counter function ・Expanded to 16 channels |

- | ||

| 1.12xx41xx (March 2025) |

Expanded counter function • Frequency • High response |

This update includes changes to the settings menu. The former menu "M15. Encoder input" will be changed to "M18. Pulse input". Configuration settings from the previous version will be automatically and seamlessly transferred to the updated menu item. |

- | |

| (1.1220xxxx) | Dynamic allocation of input/output data size (process data length) is supported in EtherNet/IP implicit messaging. • Versions earlier than 1.xx19xxxx Input Data Size: Fixed at 504 bytes Output Data Size: Fixed at 68 bytes • Versions 1.xx20xxxx or later Configurable ranges are as follows: Input Data Size: 0 ... 504 bytes Output Data Size: 0 ... 92 bytes |

Versions earlier than 1.xx19xxxx UR-ES16DT V1.0.1.EDS Versions 1.xx20xxxx or later UR-ES16DT V2.0.0.EDS UR-EE16DT V2.0.0.EDS After performing a firmware update, the correct EDS file should be selected based on the system environment. Select the appropriate update tool and system environment before performing a firmware update to avoid compatibility problems. For details on the appropriate update procedure and the required EDS file, please refer to "EtherNet/IP connection settings after firmware version upgrade" below. |

EtheNet/IP | |

| 1.1521xxxx (May 2025) |

"EtherNet/IP1.0.1" has been added to the "M2. Network type" option in the master parameter menu. When connecting via EtherNet/IP, you can now connect without reconfiguring the connection settings specified in the EDS file "UR-ES16DT V1.0.1.EDS" in the connection settings. |

Starting from this version, digital authentication is required for all tools that connect to the device. As tools without digital authentication will no longer be able to connect to the device, ensure the use of digitally authenticated tools from the versions listed below or newer. • Firmware Update To update to this version, use the following update tool: [Update tool] (Ver. 1.39 or later) Download • UR Management Tool Please use the following tool: [UR Explorer] (Ver. 0.605 or later) Download [UR_Master_manager] (Ver. 1.40 or later) Download |

EtheNet/IP | Download |

- Prior to performing the firmware update

-

Each firmware version has its own specific limitations and precautions.

Prior to performing a firmware update, verify all applicable limitations and precautions. Select the firmware version that aligns with your system environment and operational requirements before proceeding.

- Precautions when updating firmware

-

- It is essential to refer to the [Firmware Update Procedure Manual] and follow the specified steps carefully to avoid compatibility issues during the update process.

Failure to follow the correct procedure may lead to product failure or permanent damage. - Perform firmware update in the environment where the power does not turn off during the update process. If the power turns off during the update, there is a risk that this product may stop functioning.

In that case, please contact your point of purchase for assistance. - If an Ethernet communication error occurs during the update, do not turn off the power of the device.

Instead, perform the update again.

- It is essential to refer to the [Firmware Update Procedure Manual] and follow the specified steps carefully to avoid compatibility issues during the update process.

Supported features by firmware version

This list provides an overview of the additional and enhanced features supported in each firmware version.

UR-MS16DT, UR-ME16DT

| Firmware version |

Function | |||

|---|---|---|---|---|

| Network type | Supports firmware version upgrade via direct LAN connection with a PC |

Expanded counter function ・Expanded to 16 channels |

Expanded counter function • High response |

|

| 1.06xxxx01 | CC-Link IE Field | |||

| CC-Link IE TSN | ||||

| 1.10xxxxxx | CC-Link IE Field | |||

| CC-Link IE TSN | ✓ | |||

| 1.21xx40xx | CC-Link IE Field | ✓ | ||

| CC-Link IE TSN | ✓ | ✓ | ||

UR-ES16DT, UR-EE16DT

| Firmware version |

Function | ||||

|---|---|---|---|---|---|

| Network type | Expanded Counter function ・Expanded to 16 channels |

Dynamic allocation of input/output data size (process data length) is supported in EtherNet/IP implicit messaging |

Expanded counter function • High response |

connection settings defined in "UR-ES16DT V1.0.1.EDS" |

|

| 1.05xxxx01 | - | ✓ | |||

| 1.10xx40xx | - | ✓ | ✓ | ||

| 1.12xx41xx (1.1220xxxx) |

- (EtherNet/IP) |

✓ | ✓ | ✓ | |

| 1.1521xxxx | EtherNet/IP | ✓ | ✓ | ✓ | ✓ |

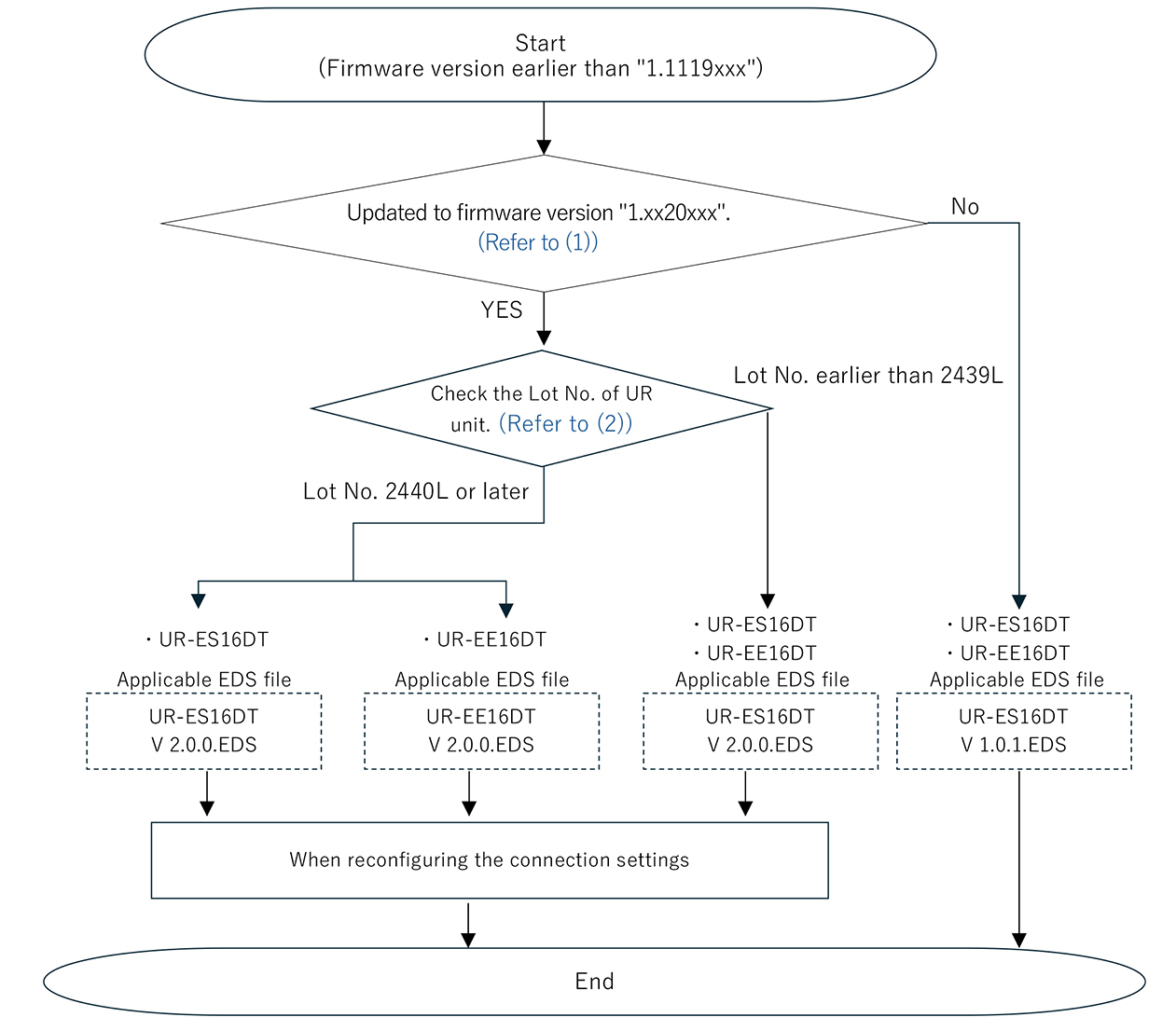

EtherNet/IP connection settings after firmware update

If the firmware is updated from version earlier than "1.1119xxxx" to "1.1220xxxx" or later while using EtherNet/IP, the existing connection settings may no longer be valid, and communication may fail.

After updating the firmware, please follow one of the connection flowcharts below according to your system environment to establish an EtherNet/IP connection.

● When reconfiguring the connection settings using the appropriate EDS file

Select the appropriate EDS file based on your system environment, and configure the EtherNet/IP connection accordingly.

● When connecting without changing existing connection settings

(Firmware version "1.1521xxxx" or later)

The master configuration of UR unit, “M2. Network type,” allows you to use the existing connection settings used before the update without having to replace the EDS file.

(1) Check the firmware version

- 1) After turning on the device, check the information shown on the display.

- 2) Show the "?-2. Master Settings Menu" on the display.

- 3) Show the "M60. Version No."

- 4) Check the firmware version number.

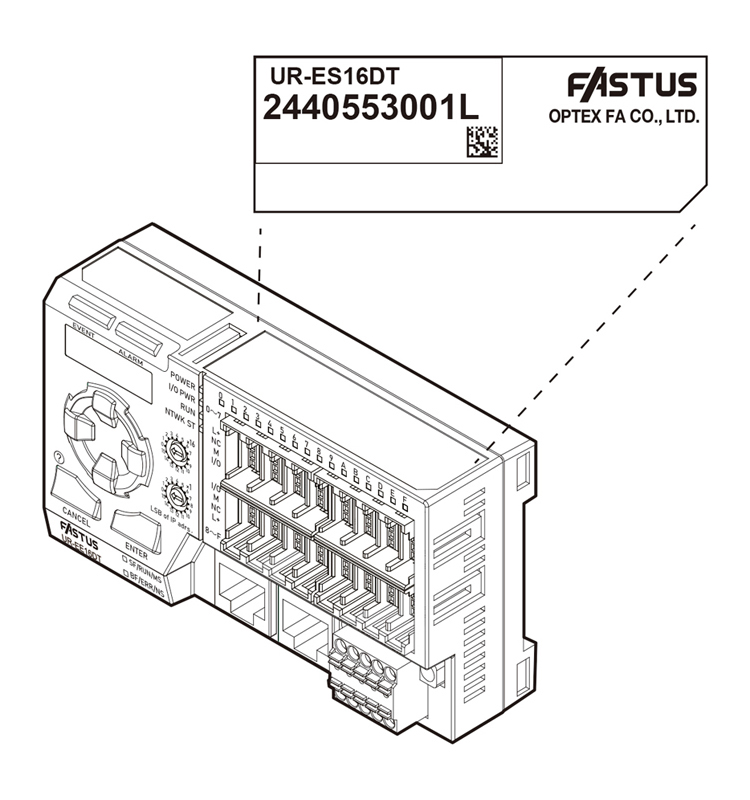

(2) Check the device lot number

The following methods can be used for verification:

• Refer to the label attached to the device.

Refer to the 11-digit* number printed on the top surface of the device.

*If the label shows a number in the format "2440xxxxxxL", the Lot No. is "2440L".

• Refer to the 5-digit number printed on the outer box of the device.