Displacement Sensors

Automotive

- Measuring workpiece height for deburring machines

- Wear measurement of hanger conveyor rails

- Inspecting stopping accuracy of robots

- Detecting seal material on pressed products

- Wind-off Measurement of Secondary Battery Film

- Measuring surface flatness of the transmission

- Detecting a hole on the shaft

- Measuring length of the protruding pipe and height of the bolt

- Measuring position of the metal plate

- Sorting by pattern of grooves on the shaft

- Positioning of robot arm

- Checking type of the parts for automotive by measuring size

- Checking type of the parts for automotive by measuring width of groove

- Measuring inner diameter of pipe

- Checking contamination of surface of the disk brake

- Checking existence and position of O-ring

- Checking amount of sealing object supplied

- Checking quality of door parts assembly

- Measuring thickness of brake disk

- Checking double fed plate

- Guiding position of welding

- Checking gap and height difference of the door and body

- Checking parts height on the brake pad assembly

- Checking quality of the rivets

- Measuring deviation of shaft axis

- Measurement of brake pad warpage

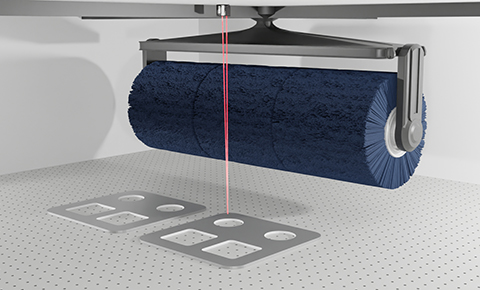

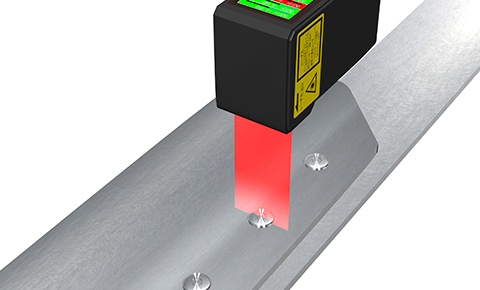

Measuring workpiece height for deburring machines

Displacement sensors can be used to measure the height of a workpiece to control the level of a deburring brush.

The CD2H-700 can perform measurement at ranges up to 1200 mm, so the sensors can be placed so that they do not interfere with the movable range of the brush, which allows for stable measurement.

Model: Laser Displacement Sensors CD2H-700

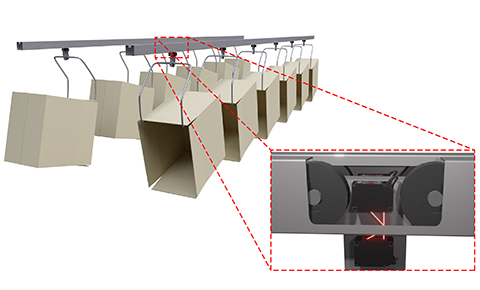

Wear measurement of hanger conveyor rails

The CD22 series laser displacement sensor can be used to measure wear on the rail of a hanger conveyor.

Regular measurement using a maintenance trolley with two laser displacement sensors installed on it makes it possible to determine when maintenance is needed.

With the smallest size (W17.8 × D32 × H44.4 mm) in its class, the CD22 series can be installed inside the rails, allowing for constant measurement to help improve maintainability.

Model: Compact Laser Displacement Sensors CD22 Series

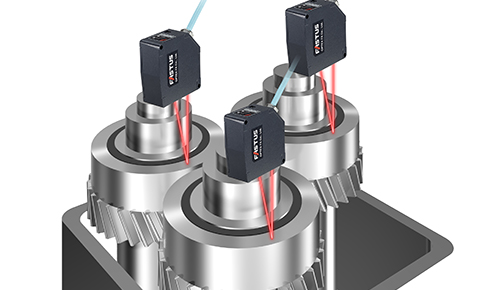

Inspecting stopping accuracy of robots

Laser displacement sensors can be used to inspect the stopping accuracy of an articulated robot.

By installing the sensors on the X, Y, and Z-axis, it is possible to check if the stopping position of the robot is within the tolerance range.

With the highest repeatability of 0.25 µm in its class, the CD2H-30 ensures highly accurate measurement.

This series is also compatible with IO-Link, so measured values can be immediately logged using dedicated free software.

Model: Laser Displacement Sensors CD2H-30

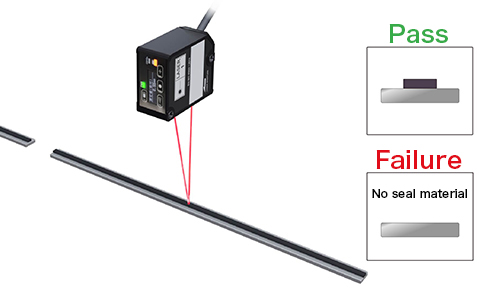

Detecting seal material on pressed products

The CD2H series makes it possible to detect seal material on pressed products.

The CD2H-2452 achieves a repeat accuracy of 10μm and a linearity of ±0.1% of FS, and can measure even minute height differences. Equipped with the same ultra-sensitive ATMOS image sensor as the most advanced displacement sensor CDX series, the CD2H series is also highly resistant to influence from materials and colors, ensuring accurate presence detection.

Model: Laser Displacement Sensors CD2H-2452

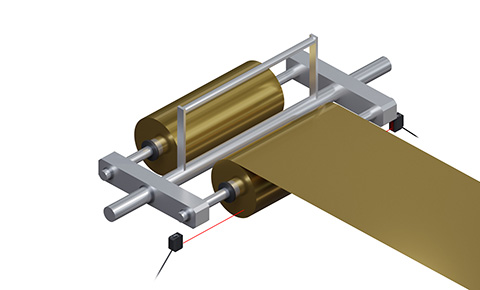

Wind-off Measurement of Secondary Battery Film

The width of a secondary battery film can be measured using two CD2H series laser displacement sensors.

The width is measured by placing sensors at both ends of the roll and calculating the measurement values of both sensors.

Since the CD2H-700 can perform long-distance measurement at ranges up to 1,200 mm, the sensors can be placed in positions where they will not interfere with the moving parts of equipment. In addition, the sensors can be used for workpieces with a variety of widths without changing the setup as the measurement range is 1,000 mm.

Model: Laser Displacement Sensors CD2H Series

Measuring surface flatness of the transmission

Measuring flatness of the transmission by laser displacement sensor CDX series.

Contact type displacement sensors were used for this application to get sufficient accuracy so far though, measuring with high accuracy is possible by CDX series which has world's best linearity.

CDX greatly contributes improving efficiency on longer life and easier maintenance.

Model: Ultra High-Accuracy Laser Displacement Sensor CDX Series

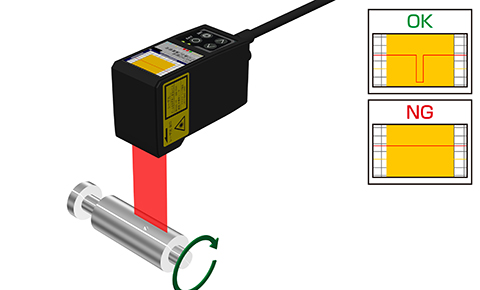

Detecting a hole on the shaft

Detecting a hole on the shaft by LS series to align the shaft at correct position.

Because the width of the detecting area is 27mm, it can detect the hold even if its position is deviated. Where small spot size standard laser sensor can't detect the hole, LS series will be able to detect it.

Model: 2D displacement sensor LS Series

Measuring length of the protruding pipe and height of the bolt

Measuring length of the protruding pipe and height of the bolt by LS series.

Measurement at multiple point of the pipe protruding from the surface and height of four bolts can be done by one LS sensor because it can measure 2 dimension, height and width.

Model: 2D displacement sensor LS Series

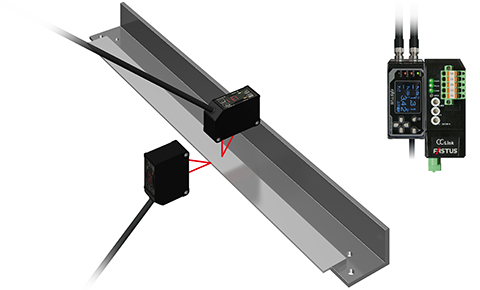

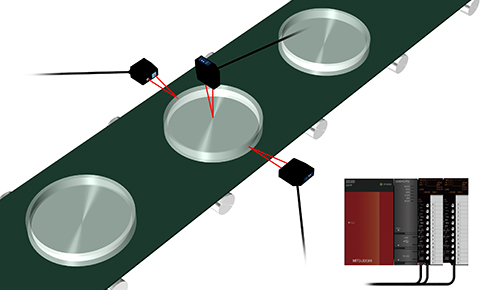

Measuring position of the metal plate

Measuring position of the metal plate by CD22.

By utilizing CDA (CD22 controller) and UC1 series (CC-Link communication unit), you can connect sensor to Mitsubishi MELSEC-Q/L series and setup, backup and measurement can be done easily and remotely.

Model: Small displacement sensor CD22 Series

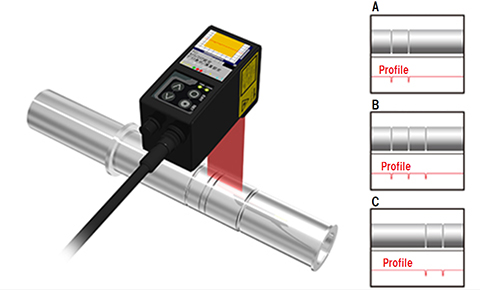

Sorting by pattern of grooves on the shaft

The LS-100CN 2D displacement sensor can be used to sort products by measuring the distance between the grooves on the metal shaft.

The LS can measure along the width of the shaft, making it possible to measure the groove spacing and quantity for sorting.

Using cameras increases the number of devices and inevitably makes system construction complicated. With the all-in-one LS, however, sorting is possible with only one device.

Model: 2D displacement sensor LS-100CN

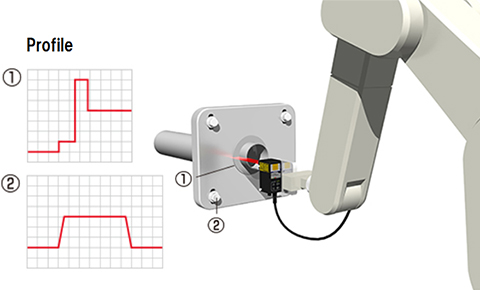

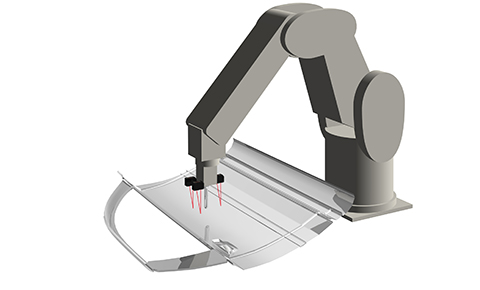

Positioning of robot arm

When you have to keep the robot arm in parallel with the surface of the objet, you can utilize 3 displacement sensor to measure the distance of 3 points (triangle) and keep the plane that the robot arm exit at parallel with the object surface.

CD22 is small and light weight so it doesn't bother installing at robot arm.

Model: Small displacement sensor CD22 Series

Checking type of the parts for automotive by measuring size

Checking type of the parts for automotive by measuring size by CD5 series.

By utilizing displacement control unit UQ1 series, you can connect multiple sensor heads to Mitsubishi MELSEC-Q series without any ladder programs in short time. You can also get measurement result and calculation result at one time.

Model: High accuracy displacement sensor CD5 Series

Checking type of the parts for automotive by measuring width of groove

Checking type of the parts for automotive by measuring width of groove by LS series.

LS series can measure not only height but also width in x axis so you can measure width of the groove on the parts and sort by type.

Model: 2D displacement sensor LS-100CN

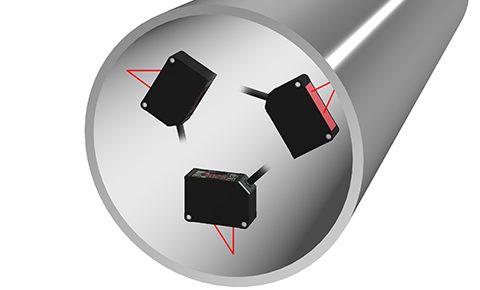

Measuring inner diameter of pipe

Measuring inner diameter of the pipe by CD22 series.

Because of small size of the CD22 series, width is only 31mm, you can measure inner diameter of the pipe installing 3 CD22 inside of the pipe.

You can also get accurate diameter by calculating with 3 measurement results even if the pipe position is deviated.

Model: Small laser displacement sensor CD22 Series

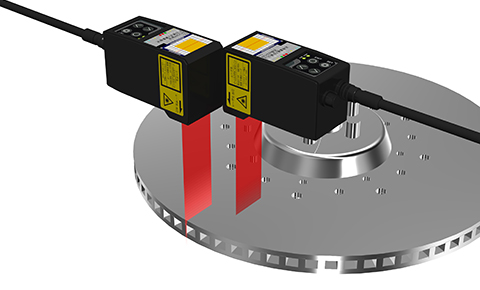

Checking contamination of surface of the disk brake

Checking contamination of surface of the disk brake by LS series.

Two LS-100CN cover the area to check contamination. The minimum detectable object will be 0.2mm.

Model: 2D displacement sensor LS-100CN

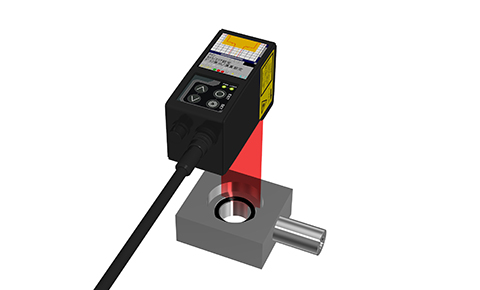

Checking existence and position of O-ring

Checking existence and position of O-ring by LS series.

It can check existence and position of O-ring with diameter less than 27mm that LS-100CN covers at one time.

Model: 2D displacement sensor LS-100CN

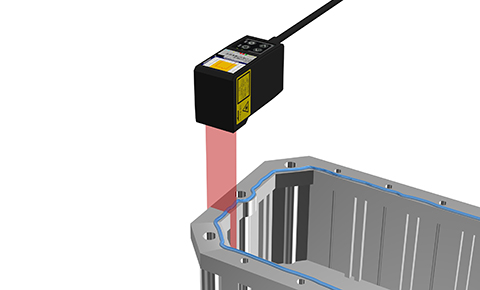

Checking amount of sealing object supplied

Checking amount of the sealing object supplied by LS series.

LS series can check width and height of object at one time so checking amount of the sealing object will be done efficiently.

Model: 2D displacement sensor LS-100CN

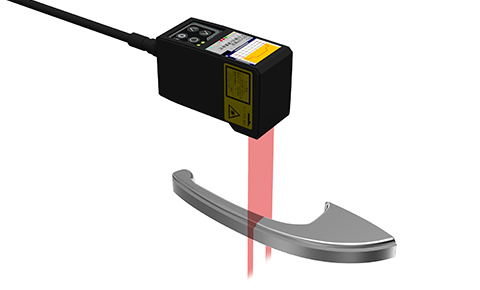

Checking quality of door parts assembly

Checking quality of door parts assembly by LS series.

It can measure not only width but also height so checking quality of door parts assembly will be done efficiently.

Model: 2D displacement sensor LS-100CN

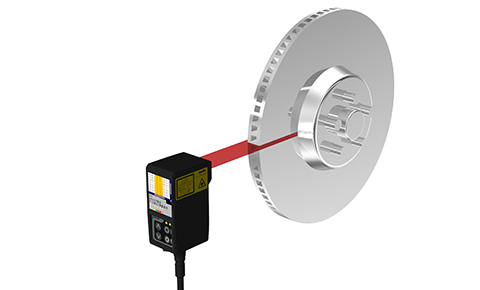

Measuring thickness of brake disk

Measuring thickness of brake disk by LS series.

You don't have to install 2 displacement sensor. One LS-100CN can measure the thickness of the brake disk. It has 27mm Max. area to measure the thickness so installation will be easy.

Model: 2D displacement sensor LS-100CN

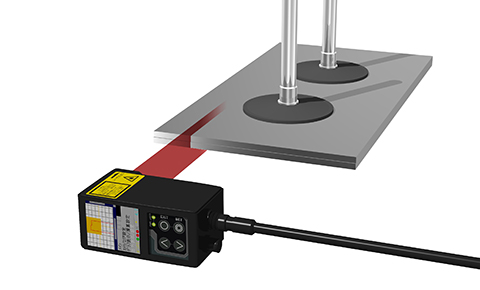

Checking double fed plate

Checking if the plate is fed double or not by LS series.

2 displacement sensor was needed to measure the thickness of the plate though, LS can measure the thickness of the plate and check if it's fed double or not from side of the plate.

You don't have to worry about collision of the sensor and picking arms.

Model: 2D displacement sensor LS-100CN

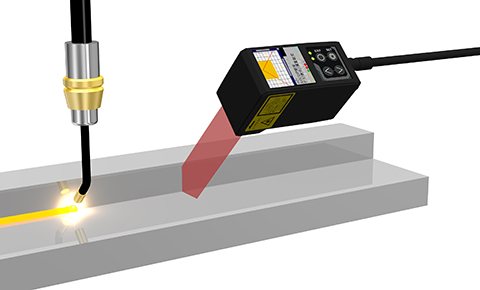

Guiding position of welding

Guiding position of welding by LS series.

It can measure the object even if the object color varies. It will help improving quality of automatic welding system providing position to guide.

Model: 2D displacement sensor LS-100CN

Checking gap and height difference of the door and body

Checking gap and height difference of the door and body by LS series.

Mechanical gauge might make scratches on the body and using multiple displacement sensor may be very difficult on positioning of those sensor heads but LS series can check and measure the gap and height difference because it has 27mm area to check width and height at one time.

Model: 2D displacement sensor LS-100CN

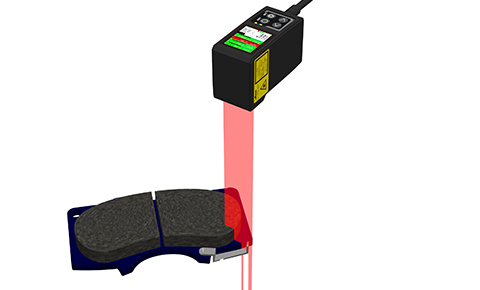

Checking parts height on the brake pad assembly

Checking parts height on the brake pad assembly by LS series.

It can measure the height of PWI (Pad Wear Indicator) installed on the brake pad assembly accurately.

You don't have to install multiple displacement sensors to check parts position and height but only one LS can check and measure them at one time.

Model: 2D displacement sensor LS-100CN

Checking quality of the rivets

Checking quality of the rivet by LS series.

It can measure height and width at one time so it can check quality of the rivet at one time efficiently.

Model: 2D displacement sensor LS-100CN

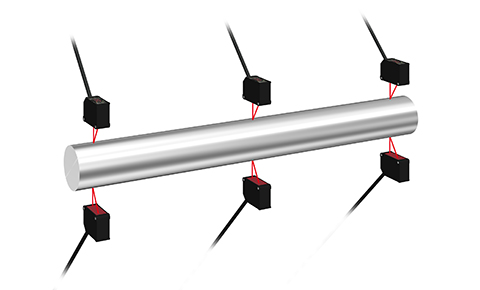

Measuring deviation of shaft axis

Measuring deviation of the shaft axis by multiple CD22 series.

CD22 has high level measurement performance utilizing its technology like "Tri-CORE" which optimizes measurement. By using multiple CD22 sensors, you can check deviation of the shaft axis.

Model: Small laser displacement sensor CD22 Series

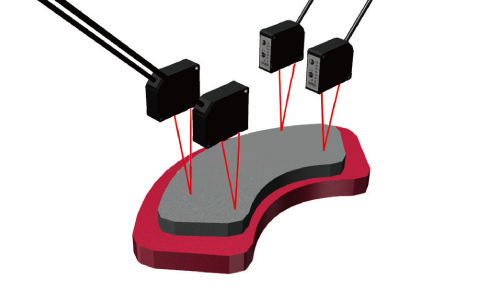

Measurement of brake pad warpage

CD33 can measure warpage of the brake pad regardless the color.

By using multiple CD33 sensors, you can measure the warpage of the brake pad.

Model: C-MOS laser displacement sensor CD33-30

Application examples

by industry

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Foods

- Beverage

- Printing

- Others