Displacement Sensors

Positioning

- Inspecting stopping accuracy of robots

- Sheet material meander control/edge measurement

- Positioning of metal parts by detecting small hole

- Detecting deviation of the cupper plate

- Positioning of index table

- Detecting a hole on the shaft

- Positioning of robot arm

- Guiding position of welding

- Check position of PV substrate

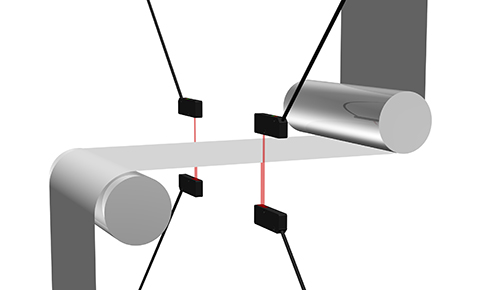

Inspecting stopping accuracy of robots

Laser displacement sensors can be used to inspect the stopping accuracy of an articulated robot.

By installing the sensors on the X, Y, and Z-axis, it is possible to check if the stopping position of the robot is within the tolerance range.

With the highest repeatability of 0.25 µm in its class, the CD2H-30 ensures highly accurate measurement.

This series is also compatible with IO-Link, so measured values can be immediately logged using dedicated free software.

Model: Laser Displacement Sensors CD2H-30

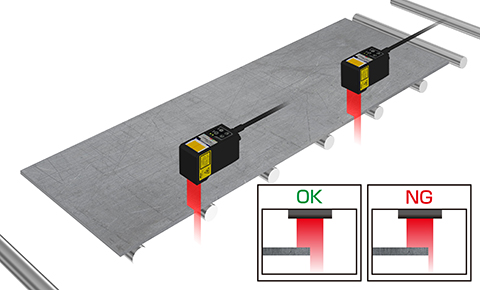

Sheet material meander control/edge measurement

The TD1 series of through-beam edge sensors help prevent sheet material meandering.

Meandering during winding in the manufacturing process can result in abnormal quality, which causes wrinkles and elongation of sheet material.

Using two TD1 series sets allows for simple meander control at up to ±10 μm. Such high-accuracy meander control enables improved yield and predictive maintenance.

Model: Through-beam Edge Sensor TD1 Series

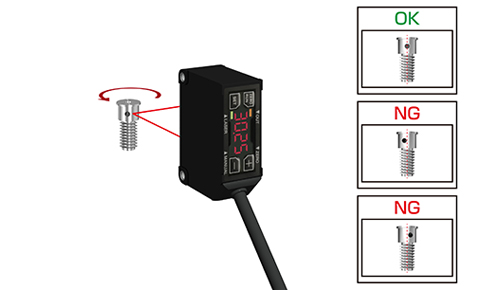

Positioning of metal parts by detecting small hole

Positioning of metal parts can be done by CD22 detecting small hole on the parts.

The spot size is very small, less than 1mm, so it can detect small hole on the parts and control position of it. Repeat accuracy of CD22 is 1μm so it can detect shallow hole.

Model: Small laser displacement sensor CD22 Series

Detecting deviation of the cupper plate

Detecting deviation of the cupper plate by LS series.

It can check deviation of the edge position of the cupper plate in X axis and also tilting of the edge at one time. It helps keeping stableness of the position and shape of the cupper plate for process at the next stage.

Model: 2D displacement sensor LS-100CN

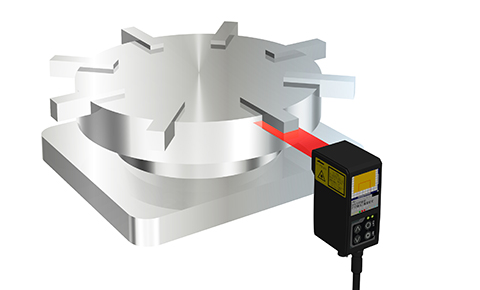

Positioning of index table

Positioning of index table by LS series.

It can measure height and width so it can monitor the position of index table accurately, with 25μm in X axis, and efficiently.

Model: 2D displacement sensor LS-100CN

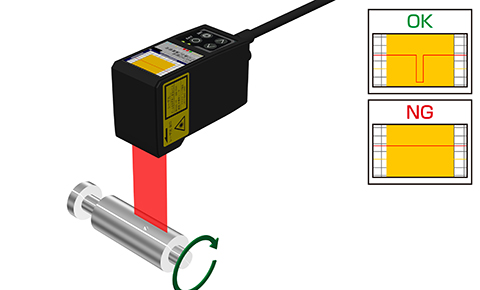

Detecting a hole on the shaft

Detecting a hole on the shaft by LS series to align the shaft at correct position.

Because the width of the detecting area is 27mm, it can detect the hold even if its position is deviated. Where small spot size standard laser sensor can't detect the hole, LS series will be able to detect it.

Model: 2D displacement sensor LS Series

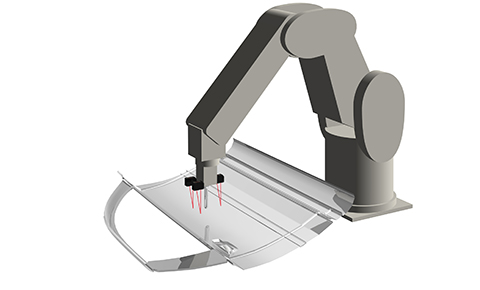

Positioning of robot arm

When you have to keep the robot arm in parallel with the surface of the objet, you can utilize 3 displacement sensor to measure the distance of 3 points (triangle) and keep the plane that the robot arm exit at parallel with the object surface.

CD22 is small and light weight so it doesn't bother installing at robot arm.

Model: Small displacement sensor CD22 Series

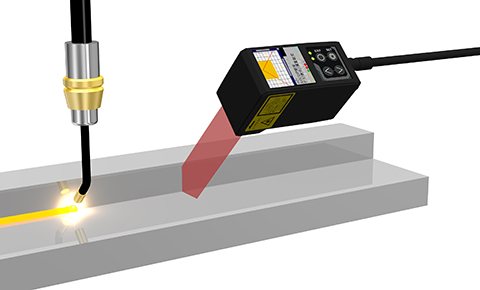

Guiding position of welding

Guiding position of welding by LS series.

It can measure the object even if the object color varies. It will help improving quality of automatic welding system providing position to guide.

Model: 2D displacement sensor LS-100CN

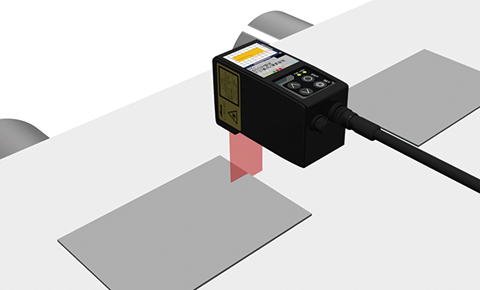

Check position of PV substrate

LS-100 series can measure position of PV silicon substrate precisely on the production line. It prevents destruction of the substrate.

Model: 2D displacement sensor LS Series

Application examples

by industry

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Foods

- Beverage

- Printing

- Others