Displacement Sensors

Machinery

- Static measurement of tension and compression test machine

- Checking amount of adhesive applied

- Measuring axis precision of the large diameter drill bit

- Measuring height of the parts assembled

- Positioning of index table

- Checking position and amount of sealing material

- Measuring Angle of Rotation

(For Inspecting Aircraft Component) - Checking shape of the parts

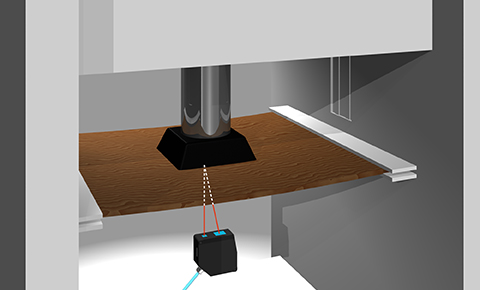

Static measurement of tension and compression test machine

Measurement of length difference of object under tension testing by laser displacement sensor CDX series.

Because of high resolution, 0.1μm, for 85mm measurement distance, measurement of subtle length difference is possible.

CDX series has synchronizing feature which enables measurement on 2 sensors at the same timing so the acquisition of two measurement results from 2 sensors without any timing difference is possible.

Model: Ultra High-Accuracy Laser Displacement Sensor CDX Series

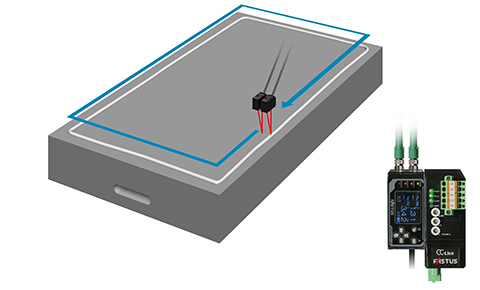

Checking amount of adhesive applied

Monitoring amount of adhesive applied by measuring height difference between peak height of the adhesive and height of the workpiece surface using laser displacement sensor CD22.

By connecting the controller CDA series and CC-Link communication unit UC1 series, CD22 series can be connected to PLC through CC-Link.

Calculation using measurement results from two sensors is also possible easily and quickly by CDA series.

Model: Small mall laser displacement sensor CD22+CDA+UC1

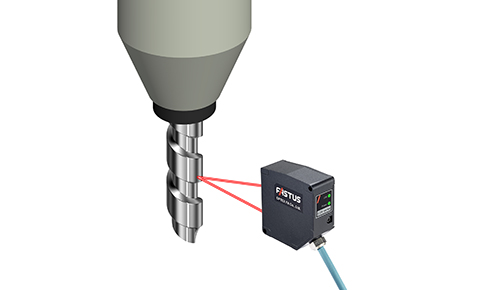

Measuring axis precision of the large diameter drill bit

Measuring axis precision of the large diameter drill bit by laser displacement sensor CDX series.

When the axis of the drill bit gets shifted, accurate machining won't be possible. By measuring axis precision by CDX, predictive maintenance on machining accuracy is possible.

The sampling period is 12.5 μs which is 8 time faster than our conventional displacement sensors which means that it can measure 80,000 times per second and can measure accurately distance of workpiece even if it turns fast.

Model: Ultra High-Accuracy Laser Displacement Sensor CDX Series

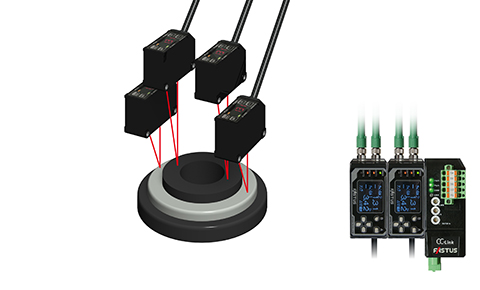

Measuring height of the parts assembled

Measuring height of the parts assembled by multiple CD22.

You can measure level deviation of the parts assembled by multiple CD22 sensors and utilizing measurement results from them.

Since CD22 is small sensor, you can install narrow space. You can also utilize displacement sensor control unit CDA to calculate level difference easily.

Communication unit UC1 will help connecting those sensors to Mitsubishi PLC very easily utilizing iQSS compatible functions (getting measurement result, setup read/write, backup, etc.).

Model: Small laser displacement sensor CD22 Series + CDA + UC1

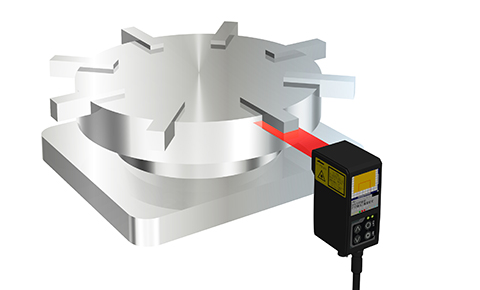

Positioning of index table

Positioning of index table by LS series.

It can measure height and width so it can monitor the position of index table accurately, with 25μm in X axis, and efficiently.

Model: 2D displacement sensor LS-100CN

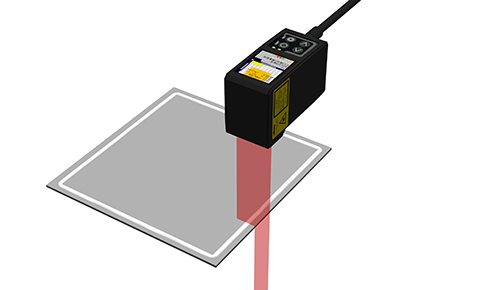

Checking position and amount of sealing material

Checking position and amount of sealing material by LS series.

Standard vision sensor can't measure amount including height of the sealing material though, LS series can measure not only height and position in X axis so you can check position and amount at one time.

Model: 2D displacement sensor LS-100CN

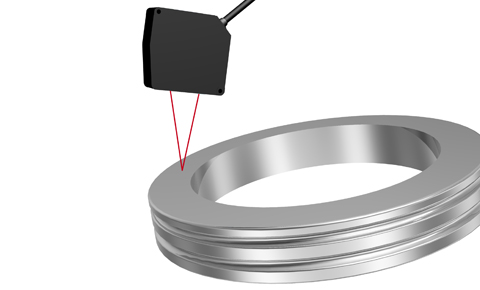

Measuring Angle of Rotation

(For Inspecting Aircraft Component)

With CD5-W85, it controls the rotation axis of non-destruction inspection equipment.

By measuring the surface of high-precision component in rotation, the angle is calculated and you can see if the processing accuracy is within the spec or not.

Model: High accuracy laser displacement sensor CD5-W85 + CD5A

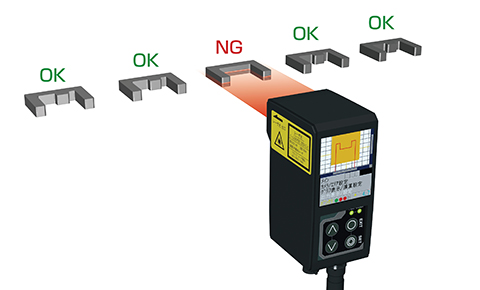

Checking shape of the parts

Checking shape of the parts by measuring height and edge position in X axis by LS series.

Its measurement range in X axis is 27mm Max. and can measure height and position of edge and check shape of the parts.

Model: 2D displacement sensor LS Series

Application examples

by industry

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Foods

- Beverage

- Printing

- Others