Displacement Sensors

Others

- Roller gap measurement

- Deflection measurement of dicing saws

- Motor vibration measurement

- Measurement of length of vibrating architectural model

- Measuring axis precision of the large diameter drill bit

- Sorting by pattern of grooves on the shaft

- Checking contamination of surface of the disk brake

- Measuring deviation of shaft axis

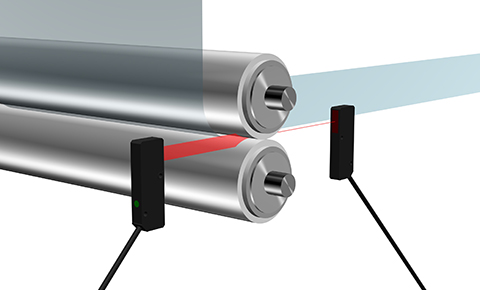

Roller gap measurement

The TD1 series of through-beam edge sensors measures the gaps between rolling rollers.

A greater gap means increased thickness, and a smaller gap means excessive thinness. Maintaining a steady gap ensures a constant rolling thickness. Control output also allows for thickness abnormalities to be output.

Model: Through-beam Edge Sensor TD1 Series

Deflection measurement of dicing saws

![]()

The CDX series of laser displacement sensors measure deflection of dicing saws.

With a spot size of ø30 μm, the CDX-30A can be used for measurement of both the side of the blade and the narrow end surface.

This allows for high-accuracy measurement for not only width but also height.

Model: Ultra high-accuracy laser displacement sensor CDX Series

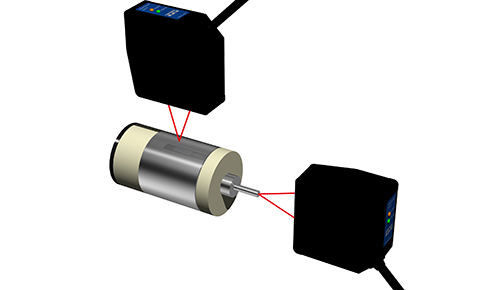

Motor vibration measurement

The CD5 series of laser displacement sensors is capable of detecting whether a motor has been correctly assembled.

With a measurement distance of 30 mm, the CD5-30 is capable of measurement with a resolution of 0.2 μm, allowing for measurement of even small amounts of vibration.

This enables reliable measurement of shaft and body vibrations that occur in motors not correctly assembled.

Model: High accuracy laser displacement sensor CD5 Series

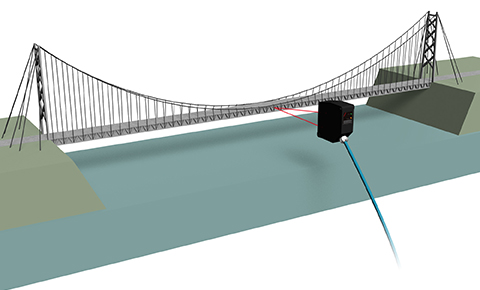

Measurement of length of vibrating architectural model

Measurement of length of vibrating architectural model by laser displacement sensor CDX series. Because of high speed measurement, 80,000 times a second, measurement of subtle length difference of the object under high speed vibration testing is possible.

It also has storage feature that enables storing of measurement data up to 100,000 points and monitoring of the data and downloading of the data as CSV file is easily possible.

Model: Ultra High-Accuracy Laser Displacement Sensor CDX Series

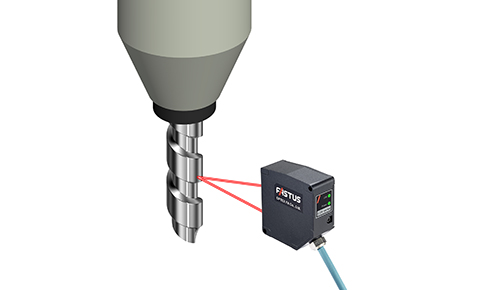

Measuring axis precision of the large diameter drill bit

Measuring axis precision of the large diameter drill bit by laser displacement sensor CDX series.

When the axis of the drill bit gets shifted, accurate machining won't be possible. By measuring axis precision by CDX, predictive maintenance on machining accuracy is possible.

The sampling period is 12.5 μs which is 8 time faster than our conventional displacement sensors which means that it can measure 80,000 times per second and can measure accurately distance of workpiece even if it turns fast.

Ultra High-Accuracy Laser Displacement Sensor CDX Series

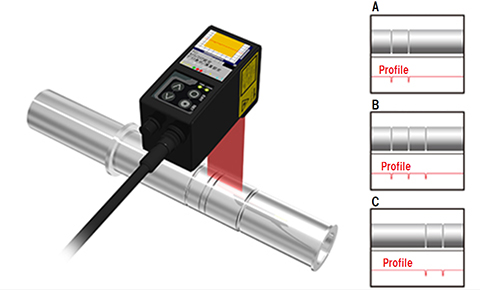

Sorting by pattern of grooves on the shaft

The LS-100CN 2D displacement sensor can be used to sort products by measuring the distance between the grooves on the metal shaft.

The LS can measure along the width of the shaft, making it possible to measure the groove spacing and quantity for sorting.

Using cameras increases the number of devices and inevitably makes system construction complicated. With the all-in-one LS, however, sorting is possible with only one device.

Model: 2D displacement sensor LS-100CN

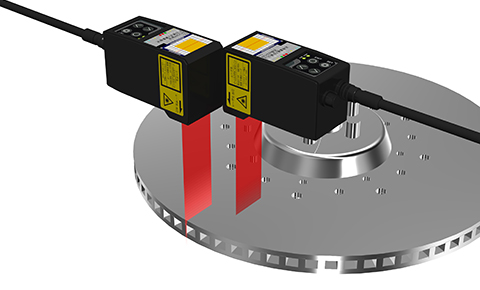

Checking contamination of surface of the disk brake

Checking contamination of surface of the disk brake by LS series.

Two LS-100CN cover the area to check contamination. The minimum detectable object will be 0.2mm.

Model: 2D displacement sensor LS-100CN

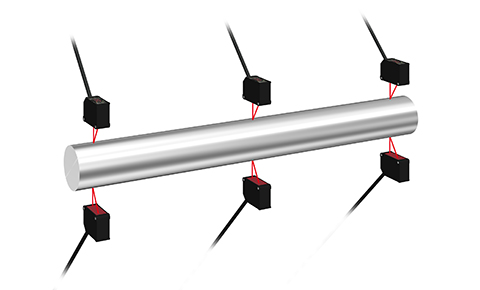

Measuring deviation of shaft axis

Measuring deviation of the shaft axis by multiple CD22 series.

CD22 has high level measurement performance utilizing its technology like "Tri-CORE" which optimizes measurement. By using multiple CD22 sensors, you can check deviation of the shaft axis.

Model: Small laser displacement sensor CD22 Series

Application examples

by industry

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Foods

- Beverage

- Printing

- Others