Photoelectric Sensors

Detecting height/level difference

- Detecting Presence of Cookies and Pass/Failure

- Mixed Juice Box Varieties and Positioning

- Silicon Wafer Misalignment Detection

- Container Loading Status Detection

- Checking distortion of aluminum frame

- Detecting fallen containers, cans for example (no need of sensors for synchronizing)

- Detecting existence and off-position of the straw

- Detecting liquid level

- Detecting fallen can on the conveyer

- Detecting parts in parts feeder

- Checking position of discrete resistor before soldering

- Checking if parts are sitting at right position or not

- Checking if PWB sitting on the plate correctly or not

- Detecting upper edge of glass/silicon wafers

- Detecting plain chewing gum protruding from the package

- Detecting piled ice cream cups

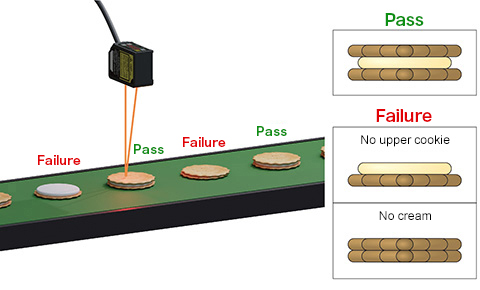

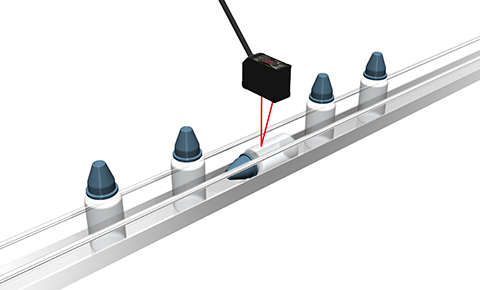

Detecting Presence of Cookies and Pass/Failure

The BGS-HDL C-MOS laser sensor can detect the presence of cookies and whether they pass or fail.

With the BGS-HDL, there are two control outputs so the presence of cookies can be detected using output 1 and whether they pass or fail can be detected by the height difference using output 2. You can reduce the number of sensors from 2 to 1 using the BGS-HDL.

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

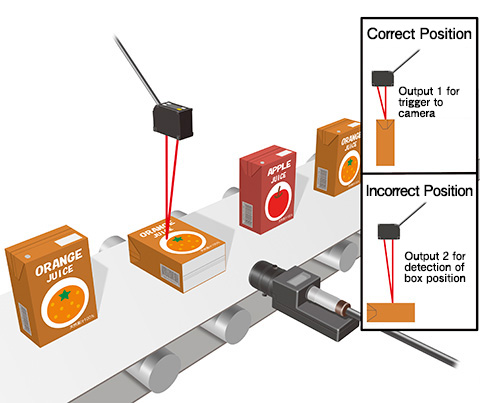

Mixed Juice Box Varieties and Positioning

The color-area mode of the MVS-PM-R pattern matching vision sensor makes it possible to detect differences in package color, preventing different varieties of packaged beverage products from being conveyed.

In addition, the BGS-HDL C-MOS laser sensor with two control outputs can be selected for the vision sensor’s trigger sensor.

The output 1 can be set for a trigger signal to the vision sensor for inspection of mixed product varieties, when a juice box passes at the correct height, leaving output 2 available to detect incorrect orientation when a juice box has fallen over on its side. In this way, both camera triggering and sideways package detection can be performed using a single sensor.

Model: Color pattern matching camera MVS-PM-R Series

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

Silicon Wafer Misalignment Detection

![]()

The BGS-HDL series enables detection of silicon wafer misalignment on a wafer stage.

Misaligned wafers can be up to 5 mm higher than normal, while the BGS-HDL05T is capable of detecting height differences of 0.08 mm, ensuring high-accuracy performance.

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

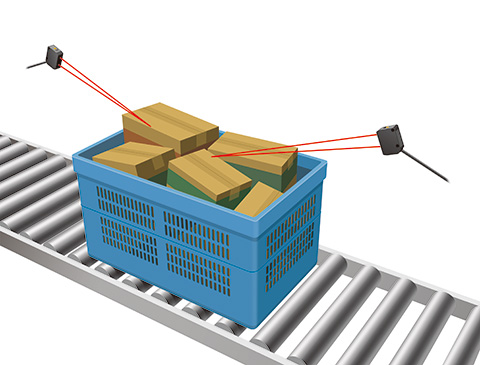

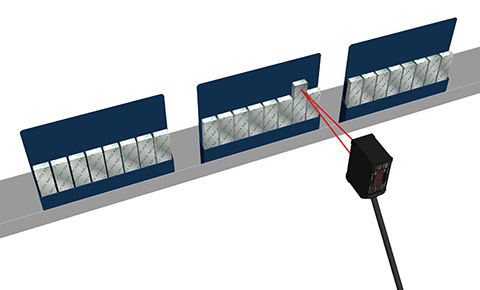

Container Loading Status Detection

The BGS-2V100N BGS sensor is able to detect whether a container is fully loaded with cartons.

Because the BGS-2V100N is configured based on distance, inspection of cartons is possible even when faced with strong influences such as the cartons being placed at different angles.

Model: BGS Sensor BGS-2V100N

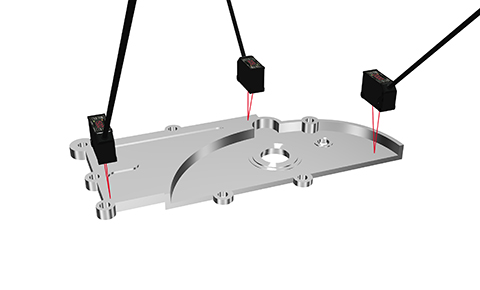

Checking distortion of aluminum frame

Distinguishing distortion of aluminum frame as "Good" or "No good" by BGS-HL05T.

Because of the minimum detectable height difference is 0.08mm, it can detect subtle distortion.

The highly reliable "Tri-CORE" engine installed also adjusts shutter speed automatically depends on the target surface reflectivity to get stable result and distinguishing distortion even for highly reflective aluminum frame is stably possible.

Model: BGS sensor with digital display type BGS-HL05T

Detecting fallen containers, cans for example

(no need of sensors for synchronizing)

C-MOS laser sensor BGS-HDL can detect fallen containers, cans for example, being transported on the conveyer.

Because BGS-HDL has 2 outputs and those threshold can be set individually, it can detect not only existence of the containers but also position or height of them without sensors for synchronizing.

Now, just one sensor can detect existence and position of the target objects where two sensors were needed to detect them.

Model: BGS sensor with digital display type BGS-HDL Series

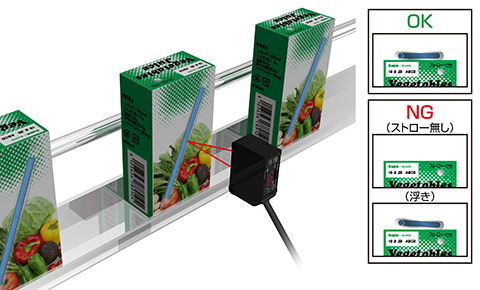

Detecting existence and off-position of the straw

C-MOS laser sensor BGS-HDL can check if the straw is attached neatly on the beverage package.

Because BGS-HDL has 2 outputs and those threshold can be set individually, it can detect not only existence of the straw but also position of it.

Just one sensor can detect existence and off-position of the straw at same time.

Model: BGS sensor with digital display type BGS-HDL Series

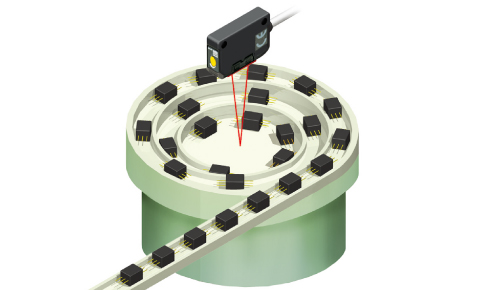

Detecting parts amount remaining in parts feeder

BGS-HDL can be utilized for controlling start/stop of feeding of parts into parts feeder bowl.

Because BGS-HDL has 2 outputs and those threshold can be set individually, it can detect not only shortage of the parts but also over feeding.

You can reduce number of sensors from 2 to 1.

Model: BGS sensor with digital display type BGS-HDL Series

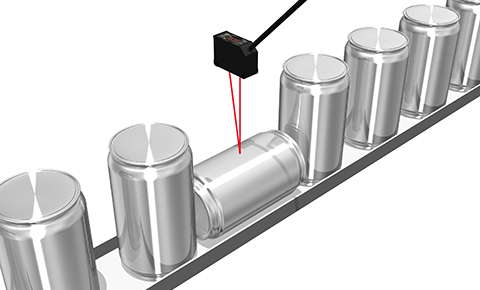

Detecting fallen can on the conveyer

Just one accurate C-MOS laser BGS sensor BGS-HL can detect fallen can on the conveyer.

The sensor has new function "ZONE Teaching", which make possible very easy teaching and detection of level of object that is in a zone. BGS-HL is also IP67 as water resistant sensor so it can be washed by water splash.

Model: Accurate laser BGS sensor with digital display BGS-HL Series

Detecting parts in parts feeder

Compact size BGS sensor BGS-S08 detects the parts running out in the parts feeder so that the operator can supply the parts before machine stops.

Model: BGS sensor BGS-S08

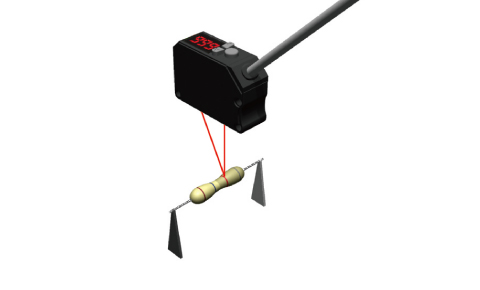

Checking position of discrete resistor before soldering

C-MOS laser sensor BGS-DL can detect a slight deviation of position of parts.

Model: C-MOS laser sensor BGS-DL10T

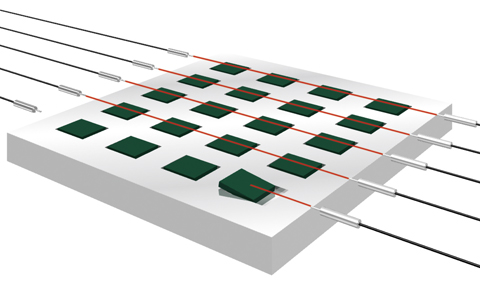

Checking if parts are sitting at right position or not

Fine spot thru-beam type Fiber-Optic Cables NF-TT01 can detect deviation of small object.

Model: Fine spot thru-beam type Fiber-Optic Cables NF-TT01

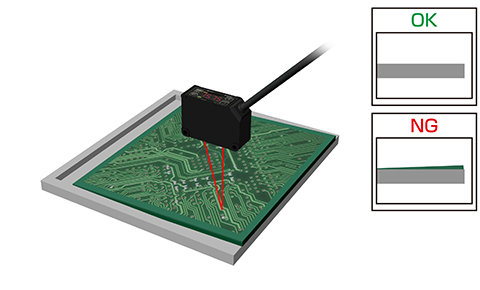

Checking if PWB sitting on the plate correctly or not

C-MOS laser BGS sensor BGS-HL25T2 can detect level difference of PWB. When the PWB is not sitting correct place on the plate, the level will be higher.

Resolution of BGS-HL25T2 is 0.8mm so it can detect small level difference even from 150mm distance above the PWB. Any color and surface condition of the PWB can be detected correctly.

C-MOS laser BGS sensor BGS-HL25T2

Detecting upper edge of glass/silicon wafers

![]()

Set teaching without work piece using thru-beam side-view type Fiber-Optic Cables.

Narrow beam of light (approximately 3 degrees angle) minimize stray reflections.

Model: Fiber-Optic Cables NF-TG04

Detecting plain chewing gum protruding from the package

High resolution laser C-MOS BGS sensor BGS-HL can detect protruding gum from the package even if the deviation is very small because the spot size of the sensor is as small as φ0.8mm.

Model: Accurate laser BGS sensor with digital display BGS-HL Series

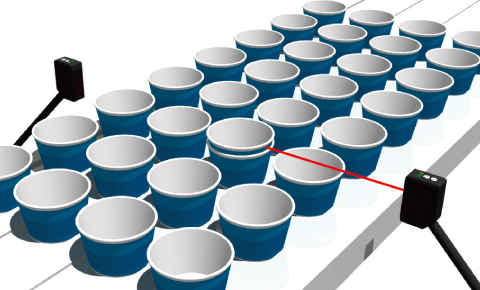

Detecting piled ice cream cups

Through beam laser sensor detects piled ice-cream cups.

The small spot size of laser finds even slight changes in height.

Model: Laser sensor ZT-L3000N

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by industry

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others