Photoelectric Sensors

Detecting direction/sides

- Detecting grains in resin-molded products

- Controlling drill bit direction

- Shaft Direction and Motor Float Detection

- Cup counting and orientation detection

- Detecting the right side of the black rubber part

- Detecting the right side of glass

- Detecting right side and wrong side of the box

- Detecting direction of syringe tray

- Detect upside-down cap

- Detecting direction of packed sweets

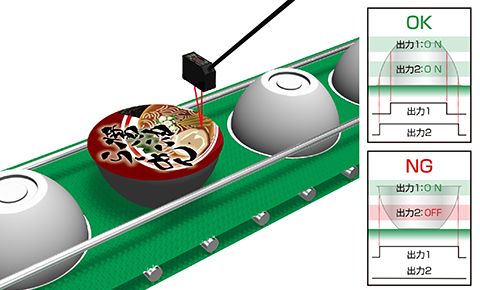

Detecting grains in resin-molded products

Using fiber sensors to detect the grains in a molded product makes it possible to determine whether a resin-molded product has been assembled correctly.

Because the grains are only about Φ4 mm, attaching the small spot lens NF-DA02 to the fiber unit allows for a smaller detection spot for easier differentiation. With no grains, the product will be nearly transparent, allowing for easy transmission of light. With grains, however, the light is diffused, increasing the received light amount and ensuring reliable detection. At a sensing distance of 15 mm, the NF-DA02 has a spot size of Φ1.4 mm, larger than that of a normal lens for more reliable identification of diffuse light and improved detection stability.

Model: Fiber Unit NF-DT01 + Small Spot Lens NF-DA02

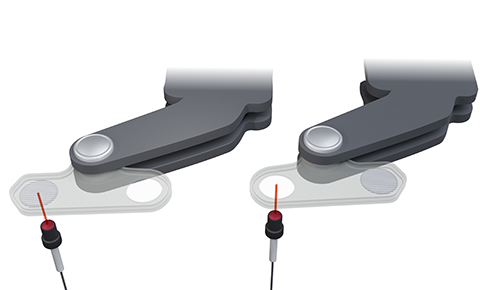

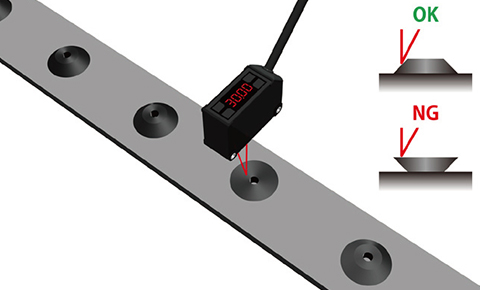

Controlling drill bit direction

The screen fiber unit NF-TZ07 can determine whether drill bits are correctly positioned during transferring.

With 32 mm width light screen, the NF-TZ07 can detect variations in the received light amount due to differences between tip and end of a drill bit, enabling reliable direction detection.

Model: Screen Fiber Unit NF-TZ07

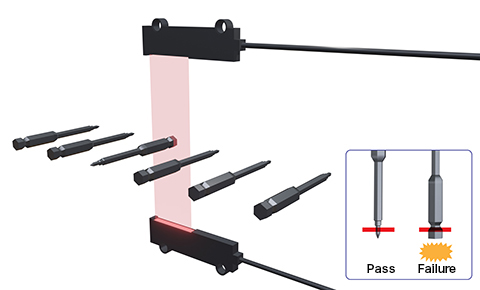

Shaft Direction and Motor Float Detection

Using the BGS-HDL series makes it possible to determine the direction of an actuator shaft and to detect floating (flange detection) when a motor is attached.

With two control outputs, the BGS-HDL series is capable of separate detections by using Output 1 for determining the shaft direction, and using Output 2 for motor float.

This means that all the work in applications that would conventionally require two sensors can be done with just a single sensor.

Model: C-MOS Laser Type BGS-HDL Series

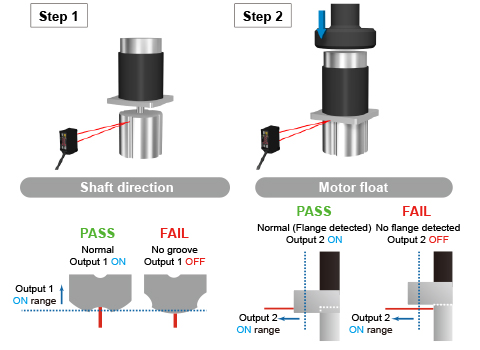

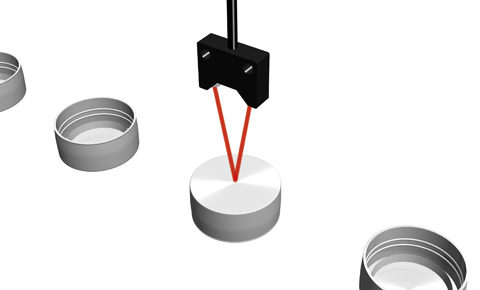

Cup counting and orientation detection

The BGS-HDL series of C-MOS laser sensors can be used for counting and detecting container orientation.

With two control outputs, the BGS-HDL series can be configured to use output 1 for container passage counting, and output 2 for orientation detection, enabling simultaneous counting and orientation detection without the need for sensor synchronization. This allows for a single sensor to perform all the work in applications that would conventionally require two sensors.

Model: C-MOS laser BGS sensor BGS-HDL Series

Detecting the right side of the black rubber part

Accurate C-MOS laser BGS sensor BGS-HL can detect the right side of the black rubber parts.

It has same image processing engine "Tri-CORE" as high end displacement sensor so it can detect black rubber even if it's tilted. It can detect objects with various colors and materials.

Model: Accurate C-MOS laser BGS sensor BGS-HL Series

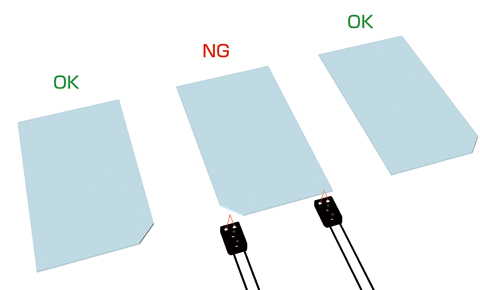

Detecting the right side of glass

Limited reflection fiber cable NF-DC38 detects the right side or wrong side of glass. NF-DC38 detects notch stably even glass is transparent.

Model: Fiber sensor amplifier + Fiber cable D3RF + NF-DC38

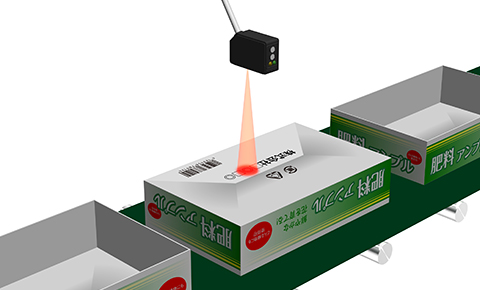

Detecting right side and wrong side of the box

Standard size BGS sensor BGS-Z10 can detect right side and wrong side of the box before goods is put into the box.

BGS-Z10 detects distance (not the amount of light received), so it can detect right side and wrong side of the box.

Model: Standard size BGS sensor BGS-Z10

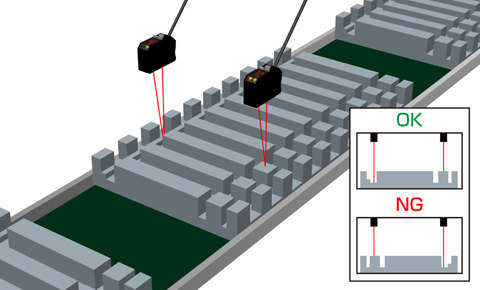

Detecting direction of syringe tray

C-MOS laser BGS sensor BGS-DL10T can detect direction of syringe tray.

Its laser spot size is φ1mm Minimum so it can detect bottom of the tray even if the groove is very narrow.

Model: C-MOS laser BGS sensor BGS-DL10T

Detect upside-down cap

Limited reflection type NF-DC09 can detect two sides of a cap.

AS Sensing distance is limited, it detects color changes of seal packing on back side.

Model: Limited reflection type NF-DC09

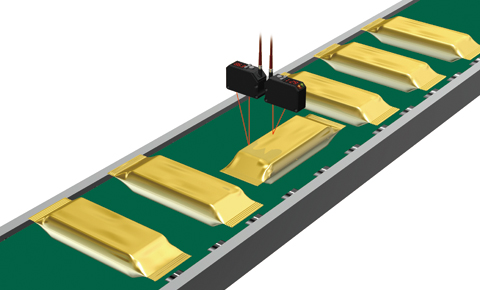

Detecting direction of packed sweets

C-MOS Laser sensor BGS-DL detects direction of packaged sweets.

Normal reflective sensor cannot detect correctly by the influences of color and lines on aluminum deposition film, but BGS-DL with C-MOS image sensor realizes stable detection.

Production line efficiency will be improved.

Model: Accurate laser BGS sensor with C-MOS image sensor BGS-DL Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by industry

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others