Photoelectric Sensors

Automotive

- Detecting grains in resin-molded products

- Controlling drill bit direction

- Positioning Automotive Components

- Shaft Direction and Motor Float Detection

- Detecting engine block on the conveyer

- Counting rolling frequency of cam

- Checking size of parts

- Detecting clips on the door assemblies

- Detecting glass plate for automotive

- Detecting body in the coating process

- Detecting wrong parts on the production line

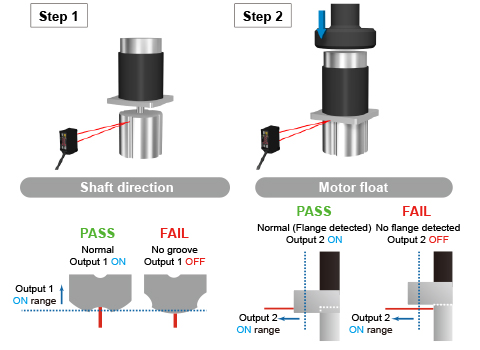

Detecting grains in resin-molded products

Using Fiber-Optic Sensors to detect the grains in a molded product makes it possible to determine whether a resin-molded product has been assembled correctly.

Because the grains are only about Φ4 mm, attaching the small spot lens NF-DA02 to the Fiber-Optic Cables allows for a smaller detection spot for easier differentiation. With no grains, the product will be nearly transparent, allowing for easy transmission of light. With grains, however, the light is diffused, increasing the received light amount and ensuring reliable detection. At a sensing distance of 15 mm, the NF-DA02 has a spot size of Φ1.4 mm, larger than that of a normal lens for more reliable identification of diffuse light and improved detection stability.

Model: Fiber-Optic Cables NF-DT01 + Small Spot Lens NF-DA02

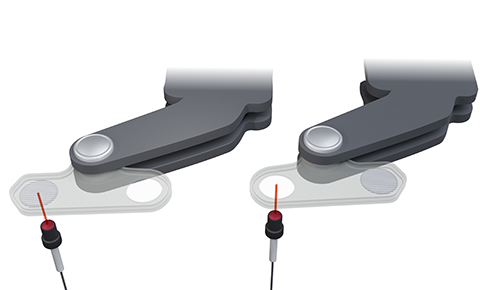

Controlling drill bit direction

The screen Fiber-Optic Cables NF-TZ07 can determine whether drill bits are correctly positioned during transferring.

With 32 mm width light screen, the NF-TZ07 can detect variations in the received light amount due to differences between tip and end of a drill bit, enabling reliable direction detection.

Model: Screen Fiber-Optic Cables NF-TZ07

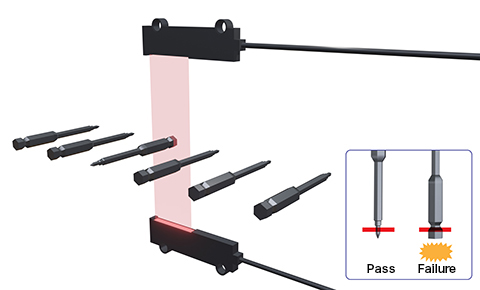

Positioning Automotive Components

The BGS-HDL series is used for positioning during automotive component assembly.

Detecting holes at an angle is difficult with photoelectric sensors, but The BGS-HDL series allows for stable detection, even when mounting is only possible diagonally, by using "AUTO mode" to always detect with the optimal sampling period.

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

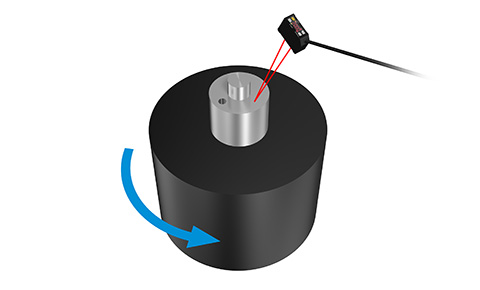

Shaft Direction and Motor Float Detection

Using the BGS-HDL series makes it possible to determine the direction of an actuator shaft and to detect floating (flange detection) when a motor is attached.

With two control outputs, the BGS-HDL series is capable of separate detections by using Output 1 for determining the shaft direction, and using Output 2 for motor float.

This means that all the work in applications that would conventionally require two sensors can be done with just a single sensor.

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

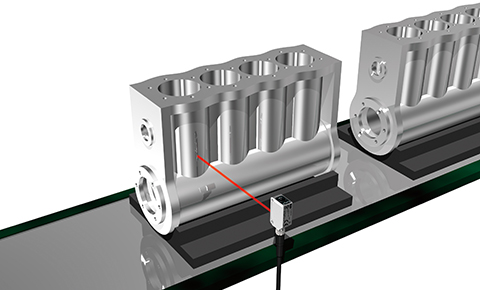

Detecting engine block on the conveyer

Stainless steel housing sensor Z-M series is good for the environment that the sensor may get oil splash especially cable for connector type has PUR sheath which is resistant to the oil.

Model: Stainless steel housing amplifier built-in sensor Z-M Series

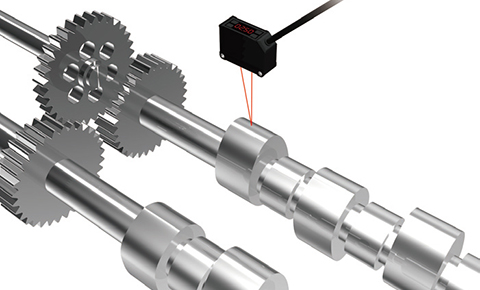

Counting rolling frequency of cam

Accurate C-MOS laser BGS sensor BGS-HL can detect metal parts stably even if the object surface get angled and reflective or not reflective because of automatic adjusting sampling frequency function.

Model: Accurate C-MOS laser BGS sensor BGS-HL Series

Checking size of parts

DSTA-200 can check the size of metal parts utilizing its 30mm width collimated light beam. It can detect object stably even if the position of the objects varies in its 30mm width beam area.

Model: Digital laser sensor head DSTA-200

Detecting clips on the door assemblies

Sensor head DSD-100 can detect small parts utilizing its laser beam.

Applied class2 laser achieves long distance detection, the parts won't get any damages from the laser beam.

Model: Digital laser sensor head DSD-100

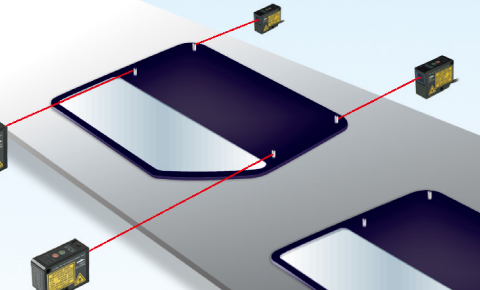

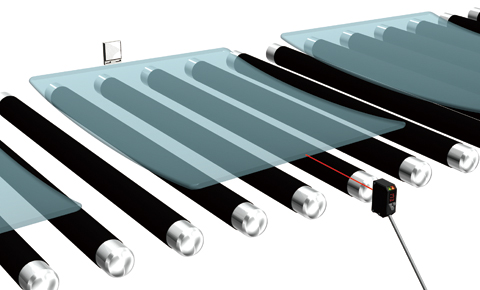

Detecting glass plate for automotive

The retro-reflective type laser sensor DR-Q400T can detect glass plate for automotive windows even if its thickness and width varies.

Model: Laser sensor for detecting transparent object DR-Q400T

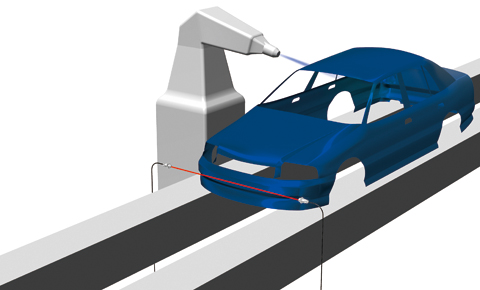

Detecting body in the coating process

Fiber-Optic Cables NF-TX01 can detect the body in the coating process.

Detection in explosion-proof area is available by mounting only Fiber-Optic Cables in coating process line.

The length of the Fiber-Optic Cables is 20m long so it can be easily handled mounted in any process line.

Model: M12 threaded thru-beam type Fiber-Optic Cables NF-TX01

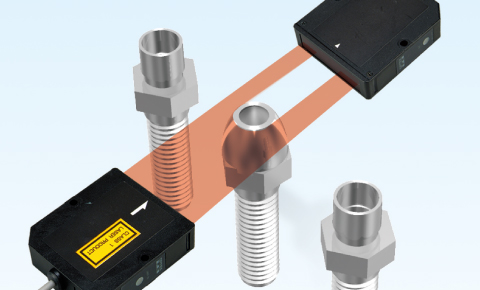

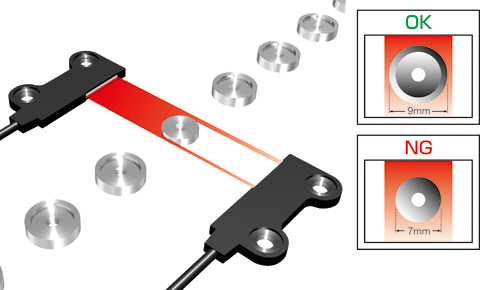

Detecting wrong parts on the production line

Fiber-Optic Sensors D3RF and screen array Fiber-Optic Cables NF-TZ09 can detect the wrong parts on the line by checking diameter of the parts.

NF-TZ09 has beam light of 11mm width and can detect objects in that area.

Model: Screen array Fiber-Optic Cables NF-TZ09

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by purpose

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others