Photoelectric Sensors

Beverage

- Mixed Juice Box Varieties and Positioning

- Detection of crushing in cans

- Detecting existence and off-position of the straw

- Detecting overlapping caps for beverage package

- Detecting transparent glass bottle through hole

- Detecting glass bottles in chemical environment

- Detect fallen can on the conveyer

- Detect upside-down cap

- Glass-bottle detection at high temperature

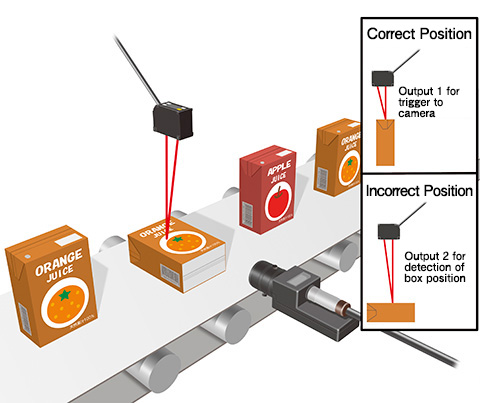

Mixed Juice Box Varieties and Positioning

The color-area mode of the MVS-PM-R pattern matching vision sensor makes it possible to detect differences in package color, preventing different varieties of packaged beverage products from being conveyed.

In addition, the BGS-HDL C-MOS laser sensor with two control outputs can be selected for the vision sensor’s trigger sensor.

The output 1 can be set for a trigger signal to the vision sensor for inspection of mixed product varieties, when a juice box passes at the correct height, leaving output 2 available to detect incorrect orientation when a juice box has fallen over on its side. In this way, both camera triggering and sideways package detection can be performed using a single sensor.

Model: Color pattern matching camera MVS-PM-R Series

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

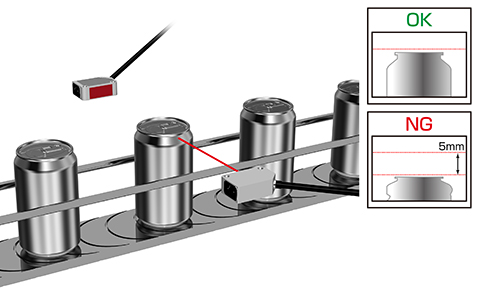

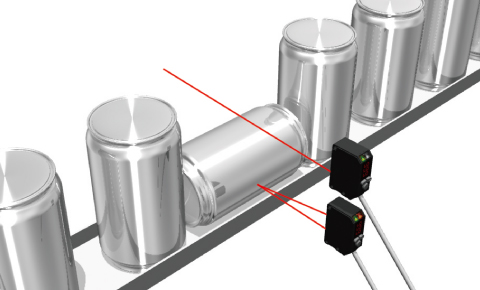

Detection of crushing in cans

Housed in stainless steel, ZT-M3000N photoelectric sensors are able to detect crushed cans on a production line.

Installing these through-beam type sensors at the height that determines whether a can is defective allows for judgment between acceptable and non-acceptable cans.

The stainless-steel housing also makes it possible to install the sensors in a caustic soda environment, which can have adverse effects on sensors with plastic housings.

Model: Stainless Steel Housing Type ZT-M3000N

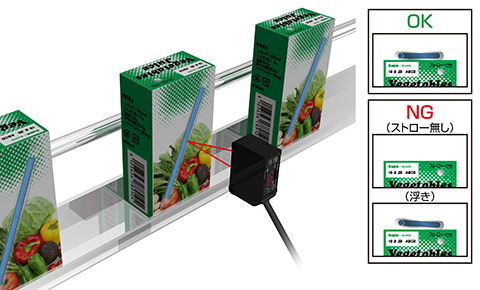

Detecting existence and off-position of the straw

C-MOS laser sensor BGS-HDL can check if the straw is attached neatly on the beverage package.

Because BGS-HDL has 2 outputs and those threshold can be set individually, it can detect not only existence of the straw but also position of it.

Just one sensor can detect existence and off-position of the straw at same time.

Model: BGS sensor with digital display type BGS-HDL Series

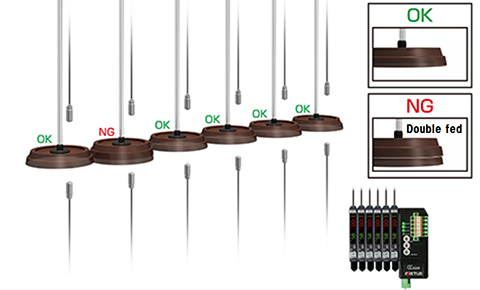

Detecting overlapping caps for beverage package

Fiber sensor amplifier D3RF and built-in lens thru-beam type fiber cable NF-TX01 can detect overlapping caps for beverage package because of high power light even if the cap is not transparent.

Controlling, saving setup and restoring setup of each fiber amplifier can be done through CC-Link utilizing communication unit UC1-CL1 connected to Mitsubishi MELSEC-Q/L series efficiently as well.

Model: UC1-CL1 + D3RF + NF-TX01

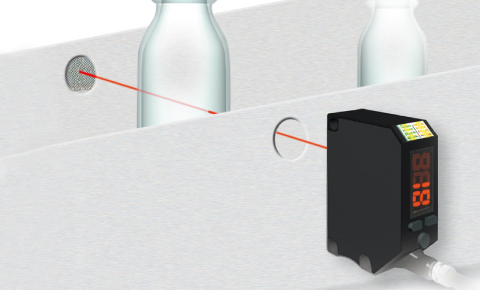

Detecting transparent glass bottle through hole

Coaxial laser type makes it possible to detect glass bottle through small hole on guide stably.

Model: Laser transparent sensor DR-Q150TCN

Detecting glass bottles in chemical environment

Transparent chemical-resistant type fiber unit NF-TY02 minimizes influences from dust and chemical vapor.

Model: Fiber sensor D2RF or D3RF + NF-TY02

Detect fallen can on the conveyer

Set sensors at lower level and higher level so that the sensors can detect only fallen cans.

As BGS-DL10TN has C-MOS image sensor, it can detect objects even if it is printed and also the surface is shiny.

Model: C-MOS laser sensor BGS-DL10TN

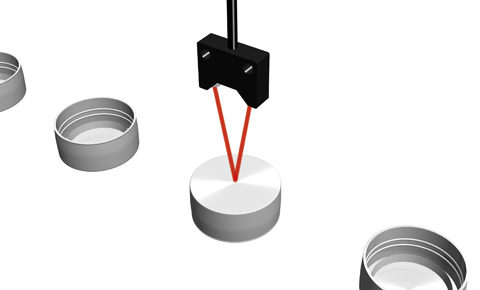

Detect upside-down cap

Limited reflection type NF-DC09 can detect two sides of a cap.

AS Sensing distance is limited, it detects color changes of seal packing on back side.

Model: Limited reflection type NF-DC09

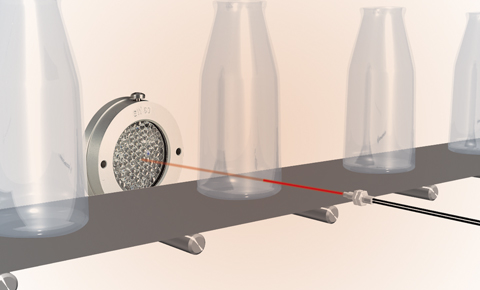

Glass-bottle detection at high temperature

The combination of heatproof NF-DH01 and heatproof reflective mirror SW50 make it possible to detect as Retro-reflective type.

Those work well for transparent detection at high temperature.

Model: Heatproof NF-DH01

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by purpose

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others