Photoelectric Sensors

Detecting wrong objects

- Component Attachment Confirmation and Product Discrimination

- Checking size of parts

- Detecting wrong parts on the production line

- Detecting wrong caps on the production line

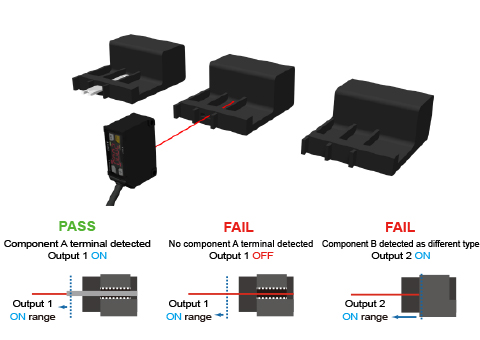

Component Attachment Confirmation and Product Discrimination

The BGS-HDL series is used for confirmation of terminals attached to breaker components and for determining product type.

The two control outputs of the BGS-HDL series are used to check for the presence of the terminal (Output 1) and to detect different product varieties (Output 2).

This eliminates the need to use two separate sensors and ensures both processes are performed using a single device.

Model: C-MOS laser BGS sensor BGS-HDL Series

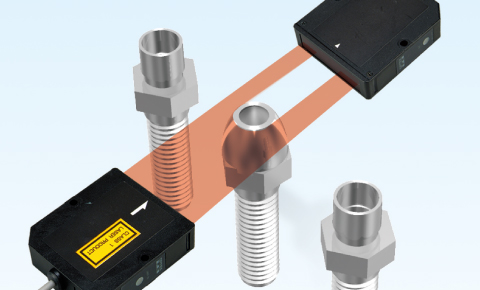

Checking size of parts

DSTA-200 can check the size of metal parts utilizing its 30mm width collimated light beam. It can detect object stably even if the position of the objects varies in its 30mm width beam area.

Model: Digital laser sensor head DSTA-200

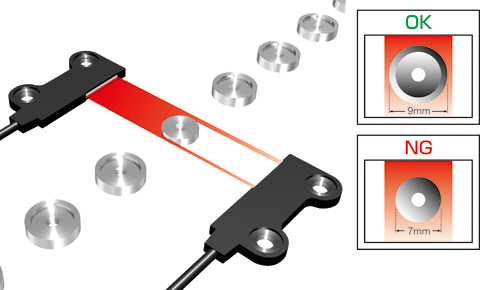

Detecting wrong parts on the production line

Fiber-Optic Sensors D3RF and screen array Fiber-Optic Cables NF-TZ09 can detect the wrong parts on the line by checking diameter of the parts.

NF-TZ09 has beam light of 11mm width and can detect objects in that area.

Model: Screen array Fiber-Optic Cables NF-TZ09

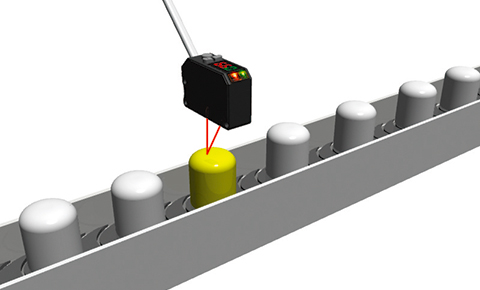

Detecting wrong caps on the production line

Color / Mark sensor DM-18T can detect wrong caps on the production line.

Teaching is very easy that just place wrong cap below the sensor at beam spot and push the teaching button. Preparation for changing product on the line will be very simple.

Model: Color / Mark sensor with digital display DM-18T

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by industry

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others