Photoelectric Sensors

Electronic Components

- Component Attachment Confirmation and Product Discrimination

- Detecting parts tray on the conveyer

- Checking IC sitting on the tray correctly or not

- Checking existence of electronic components

- Detecting parts in parts feeder

- Checking position of discrete resistor before soldering

- Detecting existence of parts

- Detecting IC in narrow space

- Detecting presence of lead wire

- Checking if parts are sitting at right position or not

- Detecting small chip parts

- etecting chip parts in high temperature environment

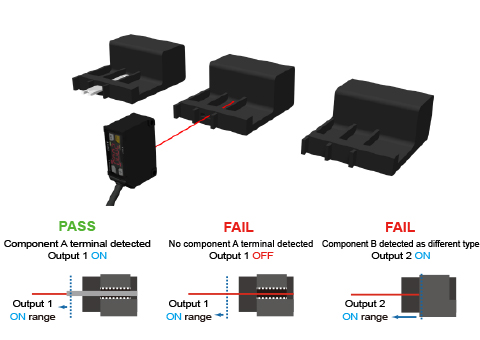

Component Attachment Confirmation and Product Discrimination

The BGS-HDL series is used for confirmation of terminals attached to breaker components and for determining product type.

The two control outputs of the BGS-HDL series are used to check for the presence of the terminal (Output 1) and to detect different product varieties (Output 2).

This eliminates the need to use two separate sensors and ensures both processes are performed using a single device.

Model: C-MOS laser BGS sensor BGS-HDL Series

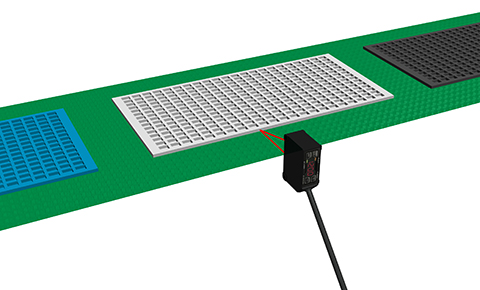

Detecting parts tray on the conveyer

C-MOS laser BGS sensor BGS-HL25T2 can detect thin trays for electric parts on the conveyer.

Its spot size is as small as φ1mm, so it can detect thin trays even if color varies.

Model: C-MOS laser BGS sensor BGS-HL Series

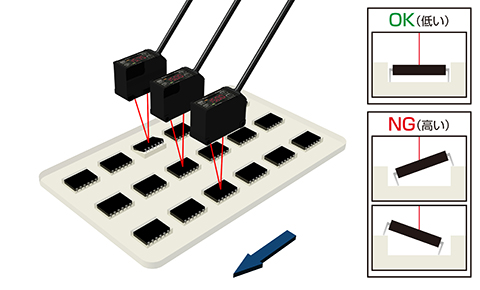

Checking IC sitting on the tray correctly or not

C-MOS laser BGS sensor BGS-HL05T can detect level difference of IC. When the IC is not sitting at correct place on the plate, the level will be higher.

Resolution of BGS-HL05T is 0.08mm so it can detect small level difference. Any color and surface condition of the IC on the plate with various colors can be detected correctly.

Model: C-MOS laser BGS sensor BGS-HL05T

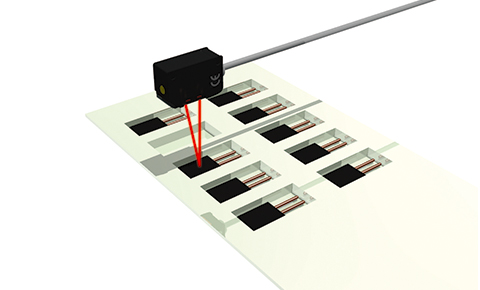

Checking existence of electronic components

Compact size BGS sensor BGS-S03 can detect existence of electronic components on the tray.

BGS sensor can detect object with any color. BGS-S03 can detect small parts because of its small spot size, φ1.5mm.

Model: Compact size BGS sensor BGS-S03

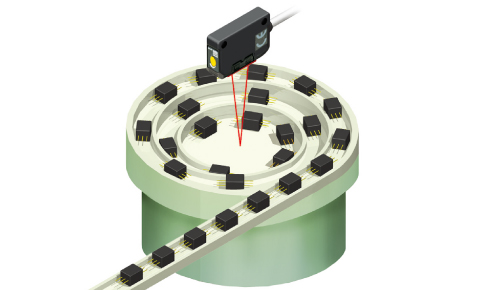

Detecting parts in parts feeder

Compact size BGS sensor BGS-S08 detects the parts running out in the parts feeder so that the operator can supply the parts before machine stops.

Model: BGS sensor BGS-S08

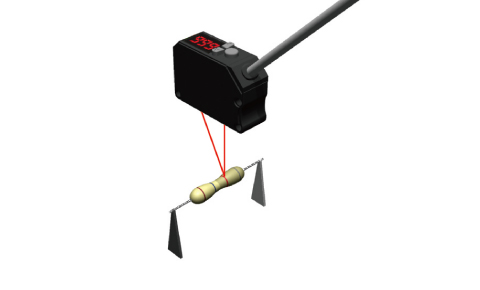

Checking position of discrete resistor before soldering

C-MOS laser sensor BGS-DL can detect a slight deviation of position of parts.

Model: C-MOS laser sensor BGS-DL10T

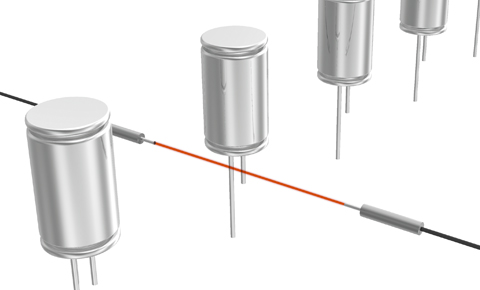

Detecting existence of parts

DSTA-200 can detect existence of small parts within its laser beam, 30mm width.

Because of the laser beam, it can detect object at unstable position. It also detects the size of vacuum pads and parts.

Model: Digital laser sensor head DSTA-200

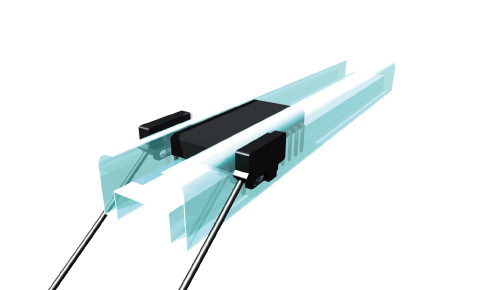

Detecting IC in narrow space

The body size of the miniature sensor ET-500 is only 3.5mm width.

It can be attached in narrow space.

Model: Miniature sensor ET-500

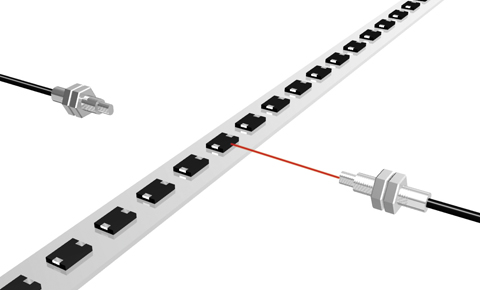

Detecting presence of lead wire

Detect thin lead wire of φ0.1mm Minimum by using NF-TT01 which has fine core.

Model: Fiber-Optic Cables for detecting of small objects NF-TT01

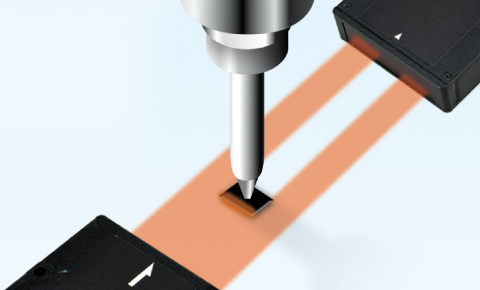

Checking if parts are sitting at right position or not

Fine spot thru-beam type Fiber-Optic Cables NF-TT01 can detect deviation of small object.

Model: Fine spot thru-beam type Fiber-Optic Cables NF-TT01

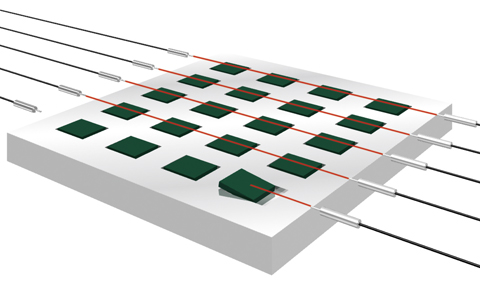

Detecting small chip parts

Small spot lens NF-DA01 and coaxial reflective type Fiber-Optic Cables NF-DK21 realize small spot size of φ0.2mm.

Stable detection for small chip parts is available.

Model: Lens for Fiber-Optic Cables to detect small objects NF-DA01(+NF-DK21)

Detecting chip parts in high temperature environment

Heat resistant Fiber-Optic Cables NF-TH02 can detect chip parts in the feeder. It can be used in high temperature up to 180℃.

Model: Heat resistant Fiber-Optic Cables NF-TH02

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by purpose

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others