Photoelectric Sensors

Rubber/Plastic

- Detecting grains in resin-molded products

- Detecting mesh sheets meander

- Detecting the right side of the black rubber part

- Detecting overlapping caps

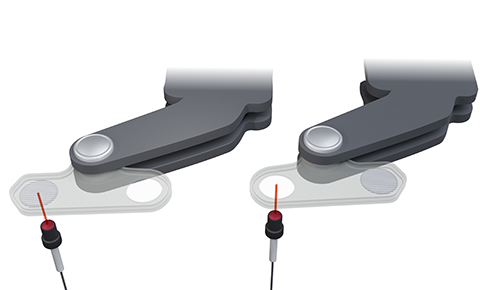

Detecting grains in resin-molded products

Using Fiber-Optic Sensors to detect the grains in a molded product makes it possible to determine whether a resin-molded product has been assembled correctly.

Because the grains are only about Φ4 mm, attaching the small spot lens NF-DA02 to the Fiber-Optic Cables allows for a smaller detection spot for easier differentiation. With no grains, the product will be nearly transparent, allowing for easy transmission of light. With grains, however, the light is diffused, increasing the received light amount and ensuring reliable detection. At a sensing distance of 15 mm, the NF-DA02 has a spot size of Φ1.4 mm, larger than that of a normal lens for more reliable identification of diffuse light and improved detection stability.

Model: Fiber-Optic Cables NF-DT01 + Small Spot Lens NF-DA02

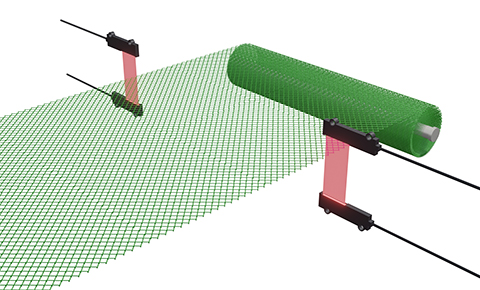

Detecting mesh sheets meander

Meander detection is possible when rewinding mesh sheets.

Installing screen Fiber-Optic Cables NF-TZ07 on each end of the sheet makes it possible to detect any movement to the left or right. With 32 mm width light screen, the NF-TZ07 also ensures stable detection even with mesh objects.

Model: Screen Fiber-Optic Cables NF-TZ07

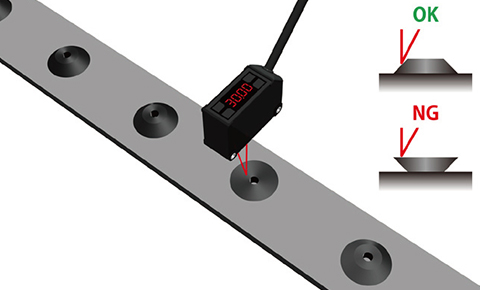

Detecting the right side of the black rubber part

Accurate C-MOS laser BGS sensor BGS-HL can detect the right side of the black rubber parts.

It has same image processing engine "Tri-CORE" as high end displacement sensor so it can detect black rubber even if it's tilted. It can detect objects with various colors and materials.

Model: Accurate C-MOS laser BGS sensor BGS-HL Series

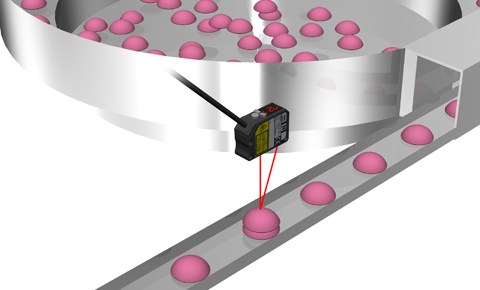

Detecting overlapping caps

C-MOS laser BGS sensor BGS-DL can detect overlapping caps in the parts feeder.

The hysteresis of 100mm sensing distance type is 3% Maximum. It can detect vey small level difference.

Model: C-MOS laser BGS sensor BGS-DL Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by purpose

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others