Photoelectric Sensors

Paper Position on Cutting Machine

- Positioning Automotive Components

- Detecting Presence, Protrusion, and Tilting of Wafers in FOUP

- Paper Position on Cutting Machine

- Alignment of glass substrate

- Detecting edge of wafer frame

- Detect glass wafer notch

- Wafer mapping (1)

- Wafer mapping (2)

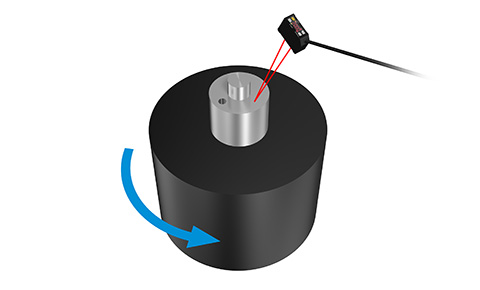

Positioning Automotive Components

The BGS-HDL series is used for positioning during automotive component assembly.

Detecting holes at an angle is difficult with photoelectric sensors, but The BGS-HDL series allows for stable detection, even when mounting is only possible diagonally, by using "AUTO mode" to always detect with the optimal sampling period.

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

Detecting Presence, Protrusion, and Tilting of Wafers in FOUP

![]()

The presence, protrusion, and tilting of wafers can be detected with two BGS-HDL series sensors.

Since the BGS-HDL series has two control outputs, the presence of wafers can be detected using output 1 and protrusion using output 2. The tilting of wafers can be detected based on the ON/OFF timing of output 1 from sensors on the left and right.

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

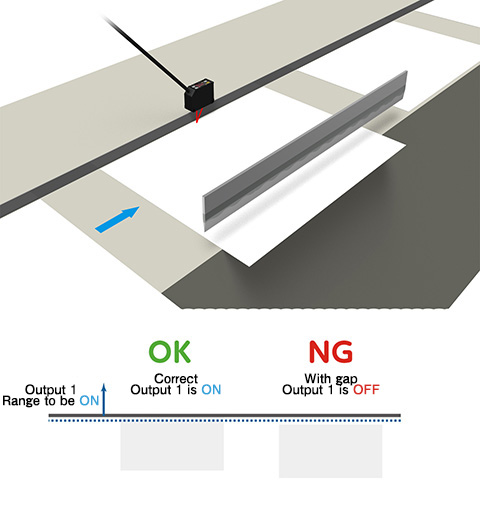

Paper Position on Cutting Machine

The BGS-HDL05T is useful for detection of paper positioning on a cutting machine.

Detection is performed when a stack of paper hits against the stopper, then the cutter blade cuts the paper to the preset size.

The BGS-HDL05T’s ability to detect a gap of just 0.08 mm ensures high-accuracy detection even with paper thicknesses up to 0.25 mm.

In addition, stable detection is possible even for glossy paper against a shiny background such as metal.

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

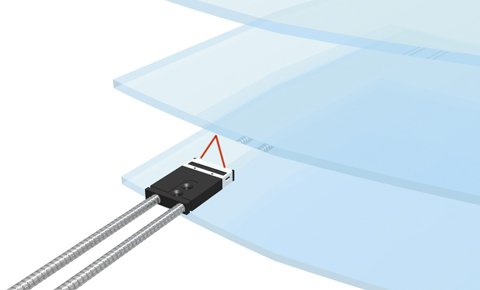

Alignment of glass substrate

Limited reflection type (heat resistant up to 250℃) enables alignment of glass substrate.

As sensor window is dual structure, detection is not affected by leaning of substrate.

Model: Limited reflection type Fiber-Optic Cables NF-DH10

Detecting edge of wafer frame

![]()

BGS-HL25t2 can detect very thin object like wafer frame because of its small spot size, φ1mm at 250mm distance from the sensor.

Model: Accurate C-MOS laser sensor BGS-HL Series

Detect glass wafer notch

![]()

By teaching at the notch, the sensor detects only the notch on the wafer and will never get influence from background because it is limited reflective type.

Model: Fiber-Optic Cables NF-DC38/DC39

Wafer mapping (1)

![]()

Narrow view type NF-TG02 has aperture angle of 2°.

It accurately detects a wafer without stray reflection.

Model: Narrow view type, wafers mapping Fiber-Optic Cables NF-TG02

Wafer mapping (2)

![]()

Wafer mapping with limited reflection type NF-DC03. Minimum detectable thickness of the wafer is 0.5mm.

Model: Limited reflective type Fiber-Optic Cables NF-DC03

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by industry

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others