Photoelectric Sensors

Beverage

- Mixed Juice Box Varieties and Positioning

- Detection of crushing in cans

- Detecting existence and off-position of the straw

- Detecting overlapping caps for beverage package

- Detecting transparent glass bottle through hole

- Detecting glass bottles in chemical environment

- Detect fallen can on the conveyer

- Detect upside-down cap

- Glass-bottle detection at high temperature

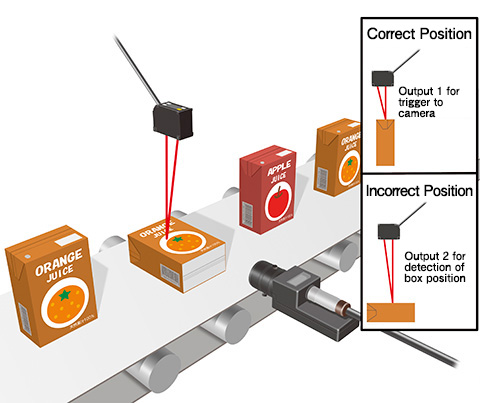

Mixed Juice Box Varieties and Positioning

The color-area mode of the MVS-PM-R pattern matching vision sensor makes it possible to detect differences in package color, preventing different varieties of packaged beverage products from being conveyed.

In addition, the BGS-HDL C-MOS laser sensor with two control outputs can be selected for the vision sensor’s trigger sensor.

The output 1 can be set for a trigger signal to the vision sensor for inspection of mixed product varieties, when a juice box passes at the correct height, leaving output 2 available to detect incorrect orientation when a juice box has fallen over on its side. In this way, both camera triggering and sideways package detection can be performed using a single sensor.

Model: Color pattern matching camera MVS-PM-R Series

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

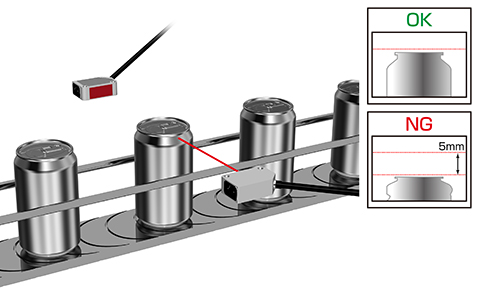

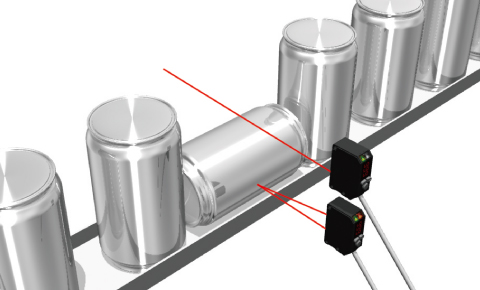

Detection of crushing in cans

Housed in stainless steel, ZT-M3000N photoelectric sensors are able to detect crushed cans on a production line.

Installing these through-beam type sensors at the height that determines whether a can is defective allows for judgment between acceptable and non-acceptable cans.

The stainless-steel housing also makes it possible to install the sensors in a caustic soda environment, which can have adverse effects on sensors with plastic housings.

Model: Stainless Steel Housing Type ZT-M3000N

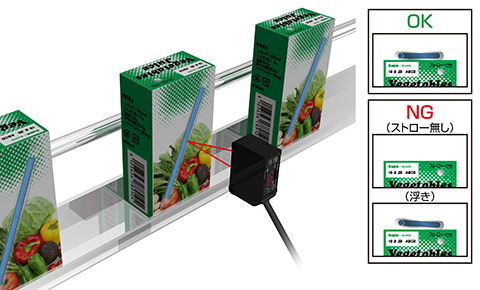

Detecting existence and off-position of the straw

C-MOS laser sensor BGS-HDL can check if the straw is attached neatly on the beverage package.

Because BGS-HDL has 2 outputs and those threshold can be set individually, it can detect not only existence of the straw but also position of it.

Just one sensor can detect existence and off-position of the straw at same time.

Model: BGS sensor with digital display type BGS-HDL Series

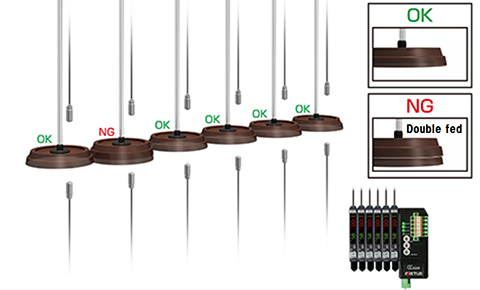

Detecting overlapping caps for beverage package

Fiber-Optic Sensors D3RF and built-in lens thru-beam type Fiber-Optic Cables NF-TX01 can detect overlapping caps for beverage package because of high power light even if the cap is not transparent.

Controlling, saving setup and restoring setup of each Fiber-Optic Sensors can be done through CC-Link utilizing communication unit UC1-CL1 connected to Mitsubishi MELSEC-Q/L series efficiently as well.

Model: UC1-CL1 + D3RF + NF-TX01

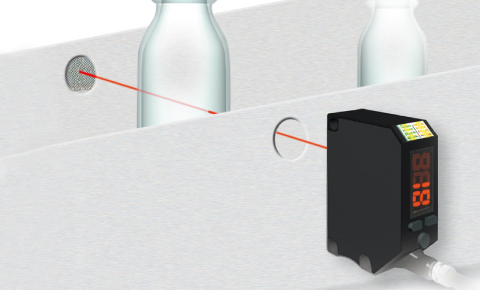

Detecting transparent glass bottle through hole

Coaxial laser type makes it possible to detect glass bottle through small hole on guide stably.

Model: Laser transparent sensor DR-Q150TCN

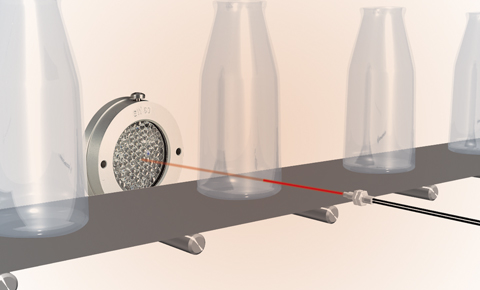

Detecting glass bottles in chemical environment

Transparent chemical-resistant type Fiber-Optic Cables NF-TY02 minimizes influences from dust and chemical vapor.

Model: Fiber-Optic Sensors + Fiber-Optic Cables D2RF or D3RF + NF-TY02

Detect fallen can on the conveyer

Set sensors at lower level and higher level so that the sensors can detect only fallen cans.

As BGS-DL10TN has C-MOS image sensor, it can detect objects even if it is printed and also the surface is shiny.

Model: C-MOS laser sensor BGS-DL10TN

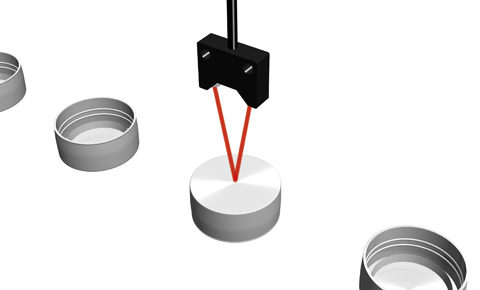

Detect upside-down cap

Limited reflection type NF-DC09 can detect two sides of a cap.

AS Sensing distance is limited, it detects color changes of seal packing on back side.

Model: Limited reflection type NF-DC09

Glass-bottle detection at high temperature

The combination of heatproof NF-DH01 and heatproof reflective mirror SW50 make it possible to detect as Retro-reflective type.

Those work well for transparent detection at high temperature.

Model: Heatproof NF-DH01

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Glass

- Printing

- Logistics

Application examples

by purpose

- Detecting existence

- Counting/Detecting passing

- Alignment/Mapping/Positioning

- Detecting direction/sides

- Detecting height/level difference

- Detecting overlapping

- Detecting protruding

- Detecting meandering

- Detecting wrong objects

- Detecting black/glossy objects

- Detecting liquid

- Long range detection

- Pin-point detection

- Detecting transparent objects

- Environmental resistant

- Detecting color and mark

- Others