Vision Sensors

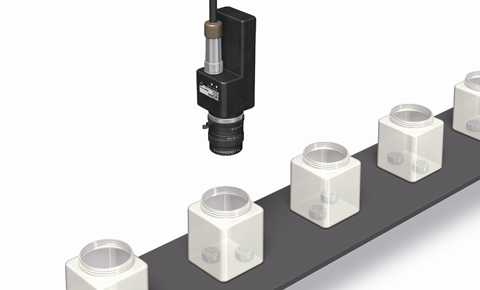

Detecting existence

- Detecting labels using a UV light source

- Presence of label on back side and print inspection of expiration date

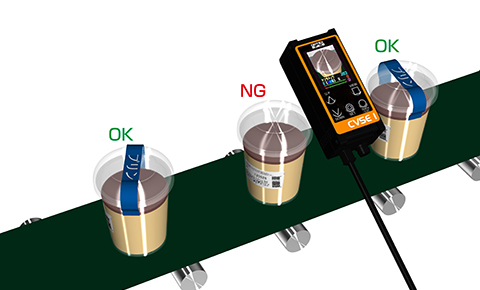

- Presence of Transparent Lids

- Checking existence of sealing tape on the carton box

- Checking existence of wrapping film on the goods

- Checking existence of groove on the metal parts

- Checking existence of washer beneath the screw

- Checking existence of plastic joint parts on the frame

- Checking existence of LOCTITE

- Checking existence of grooves at inside of the parts

- Checking existence of parts on the tray

- Checking existence of glue on the frame

- Checking existence of packaging film for CD

- Checking existence of relay on the assembly module

- Checking existence of screw locking glue on the motor shaft

- Checking existence of chamfering part at glass edge

- Checking if glass wafer is sitting correctly or not

- Detecting joint part of packaging film

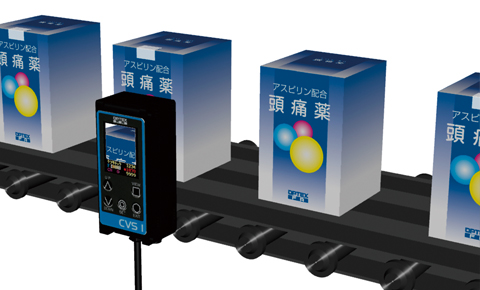

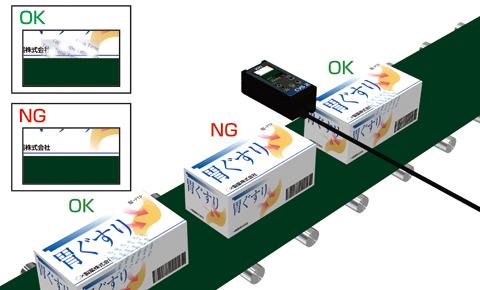

- Checking existence of description of the medicine

- Checking position of sealing tape

- Checking existence of the cap of the needle for syringe

- Checking existence of silica gel at the bottom of the bottle

- Checking existence of measure cap

- Checking existence of sealing tape

- Checking existence of notice flier

- Detecting existence of the label on the cap

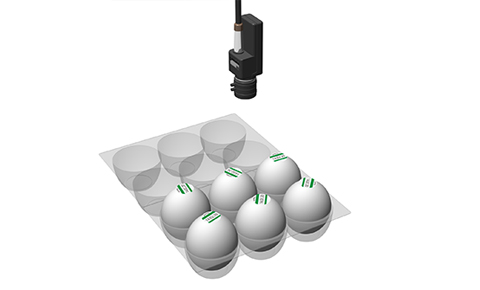

- Checking existence of label on the eggs

- Checking existence of small packages for source and mustard in a package

- Checking if the spout part is sitting correctly or not in the cap

- Checking existence of source package on chilled pizza

- Checking existence of perforation

- Checking existence of fin on the mini-bottle for soy source

- Checking existence of multiple label at one time

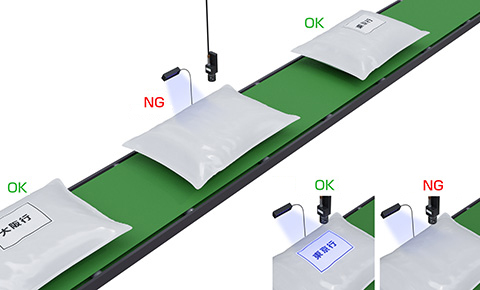

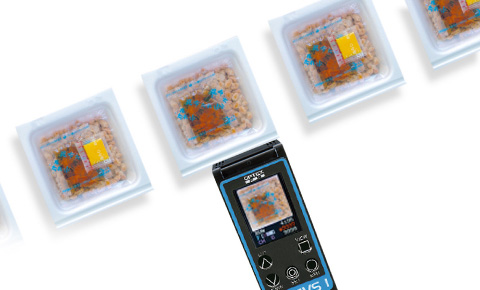

Detecting labels using a UV light source

The MVS-PM-R vision sensor detects the presence of labels by using LED lighting with a UV light source to make labels glow blue if a fluorescent component is present.

The blue glow from the fluorescent component means white labels that look the same as white backgrounds can be detected.

Model: Color pattern matching camera MVS-PM-R Series

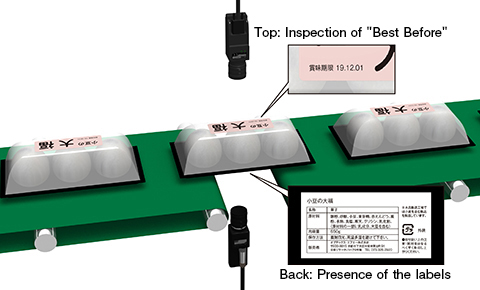

Presence of label on back side and print inspection of expiration date

MVS-PM-R of the pattern matching camera checks the presence of the back side label, and inspects the expiration date on the label with the OCR camera MVS-OCR2.

The controller MVS-DN-E can connect up to three cameras.

Since only one controller is required, it is possible to construct an inspection system with low cost.

Model: Color Pattern Matching Camera Unit MVS-PM-R Series

Model: Color OCR Camera Unit MVS-OCR2 Series

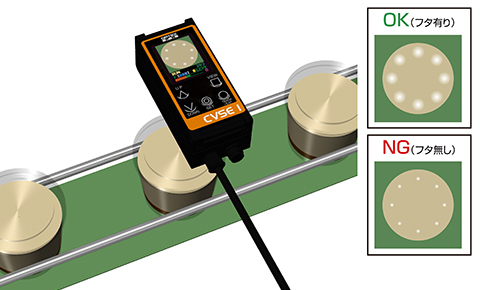

Presence of Transparent Lids

The CVSE1 easy color area sensor can be used for verifying the presence of lids on transparent containers such as for pudding.

Although detection of a transparent lid is generally difficult, installing the CVSE1 parallel to the lid and ensuring specular reflection makes detection possible by using the reflection of the built-in light source.

This ensures stable detection on production lines.

Model: Simple & Easy Setup Color Area Sensor CVSE1-RA Series

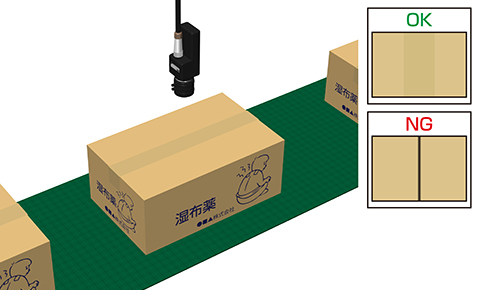

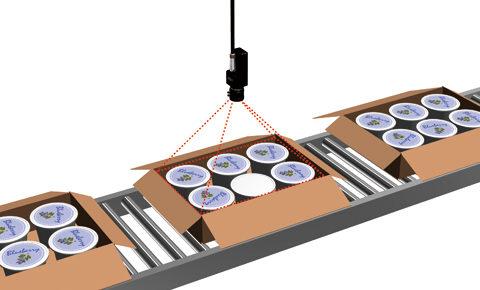

Checking existence of sealing tape on the carton box

Checking existence of sealing tape on the carton box by MVS-PM-R.

When there is no sealing tape on the carton box, it will show a line at the gap of flaps of the box. Then, the camera can detect the line easily and can reject the box.

This means that the camera can reject the box without sealing tape even if the color of the tape is same as the box.

Model: Color pattern matching camera MVS-PM-R Series

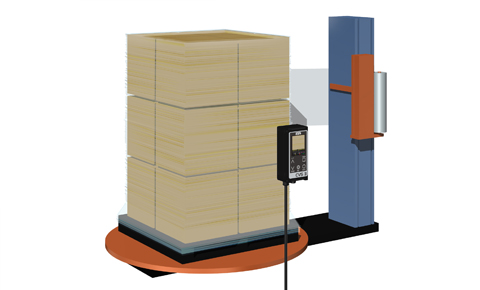

Checking existence of wrapping film on the goods

Checking existence of wrapping film on the goods by CVS3-RA series.

It can detect wrapping film on the goods by checking reflection of the light from CVS3-RA.

Model: All in one edge sensor CVS3-RA Series

Checking existence of groove on the metal parts

Checking existence of groove on the metal parts by CVS3-RA.

It can detect existence of groove on the metal parts utilizing contour detection feature. It can also check shape of the parts by detecting contour of the objects.

Model: All in one edge sensor CVS3-RA Series

Checking existence of washer beneath the screw

Checking existence of the washer beneath the screw by CVS2-RA.

It can detect color and shape so can check existence of the washer. It's all in one vision sensor so you don't have to worry about space.

Model: All in one pattern matching & color area vision sensor CVS2-RA Series

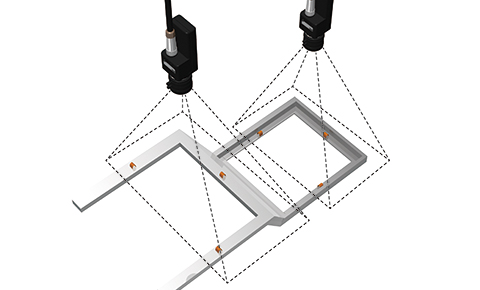

Checking existence of plastic joint parts on the frame

Checking existence of plastic joint parts on the frame by MVS-PM-R.

Since the controller MVS-DN-E can control up to 3 cameras at one time so wide area can be covered. MVS vision sensor series helps reducing cost of total system.

Model: Color pattern matching camera MVS-PM-R Series

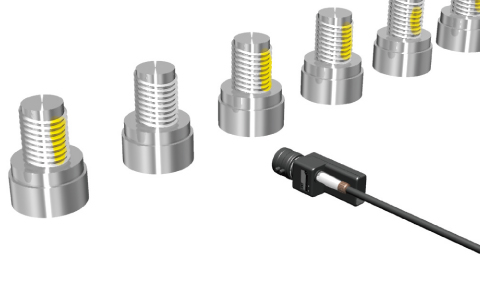

Checking existence of LOCTITE

Checking existence of LOCTITE supplied on the bolt by MVS-PM-R.

It can check color area in the inspection window and reject ones with less LOCTITE.

Model: Color pattern matching camera MVS-PM-R Series

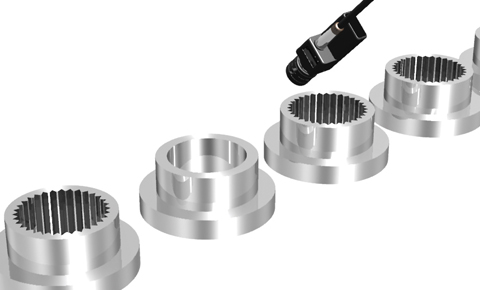

Checking existence of grooves at inside of the parts

Checking existence of grooves at inside of the parts by MVS-PM-R.

The reflection changes if there is no grooves inside of the parts. MVS-PM-R can detect the difference of reflection from the inside of the parts.

Model: Color pattern matching camera MVS-PM-R Series

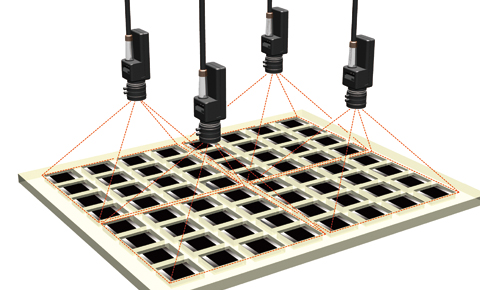

Checking existence of parts on the tray

Checking existence of parts on the tray by MVS-PM-R.

It can have up to 16 inspection windows so you can check existence of each part on the tray individually. You can get output for each inspection window as well so you know which part is missing on the tray.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of glue on the frame

Checking existence of glue on the frame by MVS-PM-R.

It can have up to 16 inspection windows so you can check existence of glue at up to 16 part of the frame at least at one time. Teach without glue and reverse the output logic so it detects NG when there is no glue on the frame.

Model: Color pattern matching camera MVS-PM-R Series

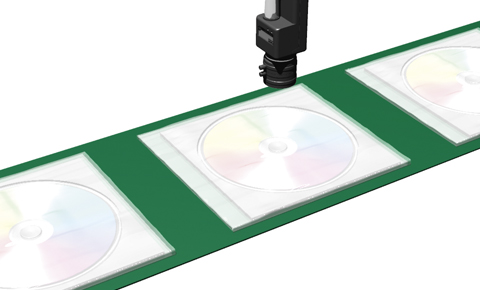

Checking existence of packaging film for CD

Checking existence of packaging film for CD by MVS-PM-R.

By aligning LED lighting so that the light reflects at the surface of the film and MVS-PM-R can get the light.

Model: Color pattern matching camera MVS-PM-R Series

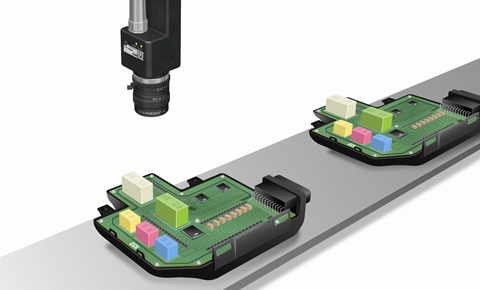

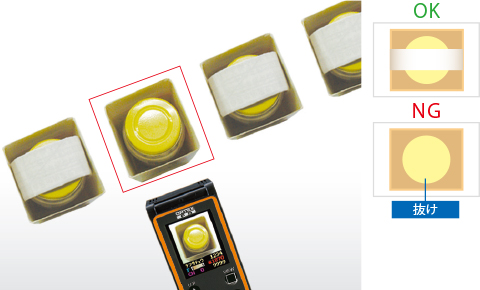

Checking existence of relay on the assembly module

Checking if the relay is mounted at correct position or not on the assembly module by MVS-PM-R.

"color and shape" function will work fine for this application detecting color area at the position of the relay.

Model: Color pattern matching camera MVS-PM-R Series

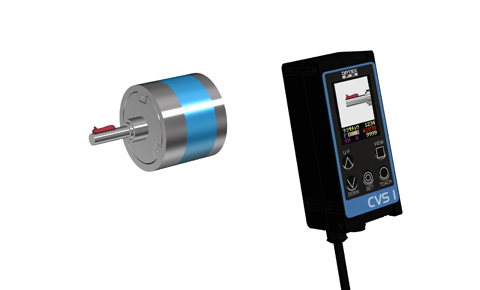

Checking existence of screw locking glue on the motor shaft

Checking existence of screw locking glue by CVS1-RA.

When the glue is on the motor shaft, the reflection changes so CVS1-RA can detect the glue even if the amount is small.

Model: Color area sensor CVS1-RA Series

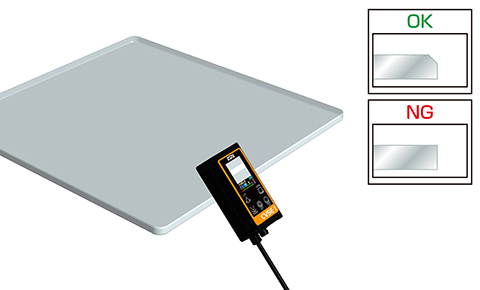

Checking existence of chamfering part at glass edge

Checking existence of chamfering part at glass edge by CVSE1-RA.

Align CVSE1-RA parallelly to the chamfering part so that it gets reflection from the chamfering surface and detect it correctly.

With wide FOV, installation of CVSE1-RA is easy and detection will be very stable.

Model: All in one color area sensor CVSE1-RA Series

Checking if glass wafer is sitting correctly or not

![]()

Checking if glass wafer is sitting correctly or not by CVS1 series.

It has wide FOV and will not get affection by water on the glass wafer so you can expect stable inspection.

Model Color area sensor CVS1-N10-RA

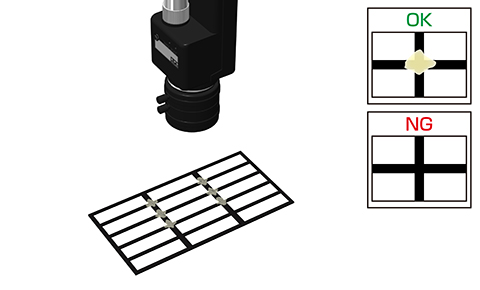

Detecting joint part of packaging film

Detecting joint part of packaging film by CVS2-RA.

It has long focal depth so it can get clear images even if the film position is deviated. It can register 2 colors so it can detect a tape at joint part of the packaging film even if those colors are similar.

Model: Pattern matching and Color area sensor CVS2-RA Series

Checking existence of description of the medicine

Because FOV of CVSE1-RA series is wide enough, it can check existence of description of the medicine stably even if the position of the description is deviated.

Model: Color area vision sensor CVSE1-N20-RA

Checking position of sealing tape

Because FOV of CVS1 series is wide enough, it can check existence of the sealing tape not only at side position but also at top side.

Model: Color area vision sensor CVS1-N20-RA

Checking existence of the cap of the needle for syringe

CVS1-RA will be able to detect the cap as white area so it can check existence of the cap of the needle.

The FOV is wide enough so it can detect the cap even if its position deviates.

Model: Color area sensor CVS1-RA Series

Checking existence of silica gel at the bottom of the bottle

By checking color area of the silica gel at the bottom of the bottle, MVS-PM-R can check amount of the silica gel even if the silica gel position at the bottom of the bottle is not stable.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of measure cap

Measure cap position may deviate so simple photoelectric sensor can't detect the measure cap stably. Even if its position is deviated, CVS2-RA which has wide FOV can detect the measure cap stably.

Model: Pattern matching and color area sensor CVS2-RA Series

Checking existence of sealing tape

Checking existence of sealing tape on the package by CVS2-RA.

Normally, it is detected by color difference though, if color difference between the tape and the package is small, you can utilize reflectivity difference of them.

Model: Pattern matching & color area sensor CVS2-RA Series

Checking existence of notice flier

Checking existence of notice flier besides of the description paper by CVS2-RA.

Photoelectric sensor won't be able to detect notice flier stably because of the height deviation of the blister package of pills though, CVS2-RA with deep focal length will be able to detect the color of the notice flier stably.

Model: Pattern matching & color area sensor CVS2-RA Series

Detecting existence of the label on the cap

Detecting existence of the label on the cap by easy all in one vision sensor CVSE1-RA.

Its color resolution is 15,000 colors and depth of focus is long so setup is very simple and easy and detects colors correctly even if the conveyer bounces.

Model: Simple & Easy setup Color area sensor CVSE1-RA Series

Checking existence of label on the eggs

By using "Stain area" function of MVS-PM-R, it can detect small labels even if its color is changed.

Model: Color pattern matching vision sensor MVS-PM-R Series

Checking existence of small packages for source and mustard in a package

CVS1 series can detect specific color area and its setup is very easy and simple.

Model: Color area sensor CVS1-N20-RA

Checking if the spout part is sitting correctly or not in the cap

Checking the shape and color of spout part in the cap and position of it by "contour" and "color area" function of MVS-PM-R.

Model: Color pattern matching camera MVS-PM-R Series

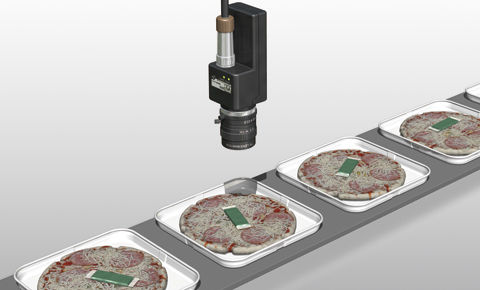

Checking existence of source package on chilled pizza

Checking existence of source package on chilled pizza utilizing "color area" function of MVS-PM-R.

The color of the source package might change depends on the temperature though, "dark compensation" function will stabilize detecting color of the package and help stable detection of the source package.

Model: Color pattern matching camera MVS-PM-R Series

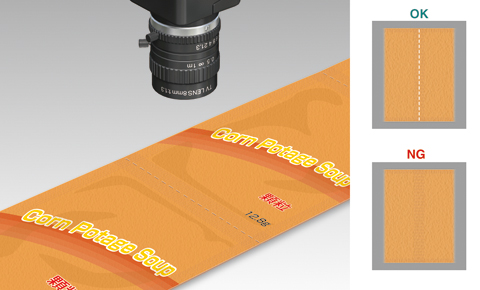

Checking existence of perforation

Checking existence of perforation by MVS-PM-R.

Utilizing backlight to make perforation visible by leakage of the light through the perforation, the color pattern matching camera MVS-PM-R will be able to detect perforation.

Model: Color pattern matching camera MVS-PM-R Series

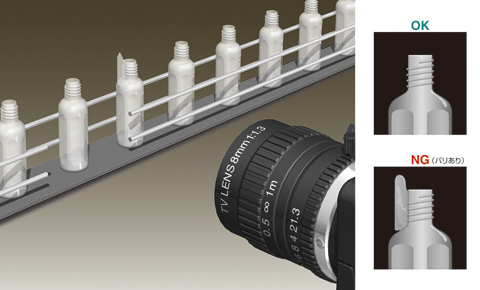

Checking existence of fin on the mini-bottle for soy source

Detecting fin on the mini-bottle for soy source by MVS-PM-R.

"contour" function of MVS-PM-R will be able to detect small fin on the mini-bottle for soy source and prevents outflow of wrong bottle to next process.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of multiple label at one time

MVS-PM-R can have up to 16 inspection windows so it can assign inspection window for each label. It can output result of each inspection window so you will be able to know which label is missing.

Model: Color pattern matching camera MVS-PM-R Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Other