Vision Sensors

Foods

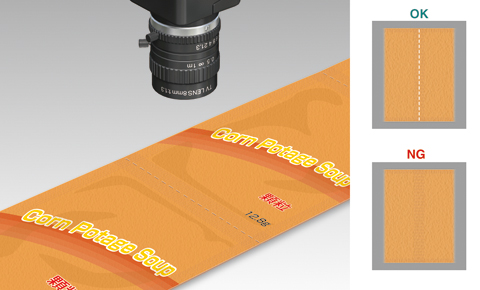

- Inspecting text printed on differently colored glossy pouches

- Ice Cream Container Lid Orientation Detection

- Recognizing coded date and time in the string

- Presence of label on back side and print inspection of expiration date

- Presence of Transparent Lids

- Chocolate arrangement monitoring

- Complex inspections of packages and marking

- Character recognition in narrow space

- Checking existence of stealth printing

- Detecting existence of the label on the cap

- Detecting deviation of the cap

- Print inspection on glossy surface

- Detecting package not sealed

- Checking shelf life and wrong box

- Print inspection of multiple packages at one time

- Character recognition and counting character number at one time

- Character recognition of laser marker printing

- Checking position of individual packaging in the box

- Checking existence of label on the eggs

- Character recognition of print on colored pattern

- Print inspection of individual packages at deviated position on the conveyer

- Print inspection of carton box (wide FOV)

- Checking combination of two chocolate sticks

- Checking existence of small packages for source and mustard in a package

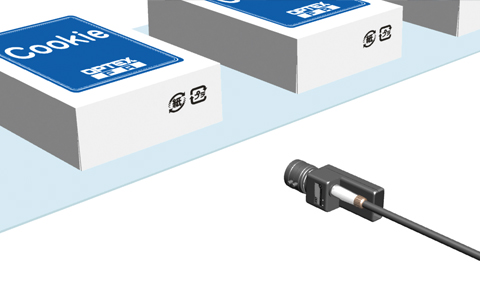

- Checking of Expiration Dates on Cartons

- Checking position of cap on container

- Checking if the spout part is sitting correctly or not in the cap

- Checking side and direction of the box

- Print inspection of gum or candy

- Checking shape of "Tempura" for instant noodle

- Print inspection on rice cake package and checking existence of antioxidant in the package

- Print inspection on two surface of the can

- Print inspection on packages of source on 3 lines

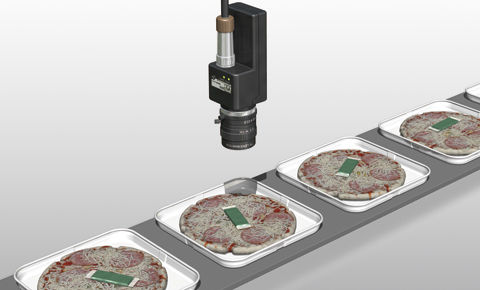

- Checking existence of source package on chilled pizza

- Checking existence of perforation

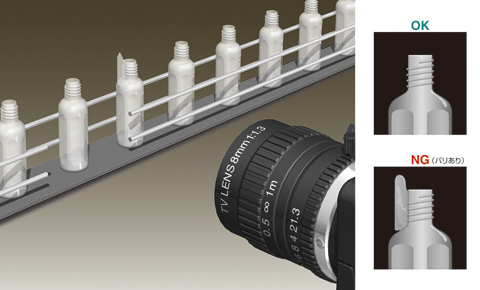

- Checking existence of fin on the mini-bottle for soy source

- Checking existence of multiple label at one time

- Checking side of package of instant noodle

- Character recognition only date part

- Character recognition of printing on the surface not even

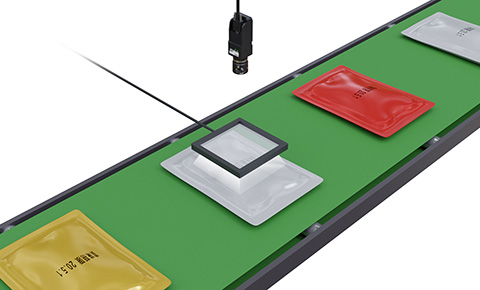

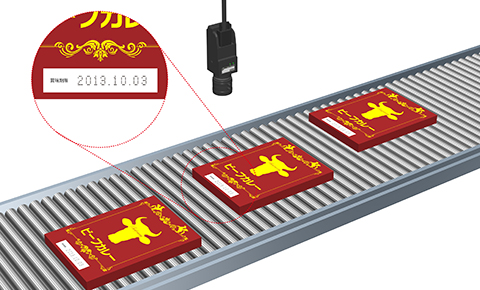

Inspecting text printed on differently colored glossy pouches

The MVS-OCR2 character recognition vision sensor can be used to inspect expiration dates printed on pouches with red, gold, or silver gloss.

The superior character extraction performance of the MVS-OCR2 enables recognition without having to change settings even for targets with different background colors.

With the addition of a flat dome lighting made by CCS Inc., the light source can be applied more evenly, ensuring stable inspection even for uneven or glossy workpieces.

Model: Color OCR Camera Unit MVS-OCR2 Series

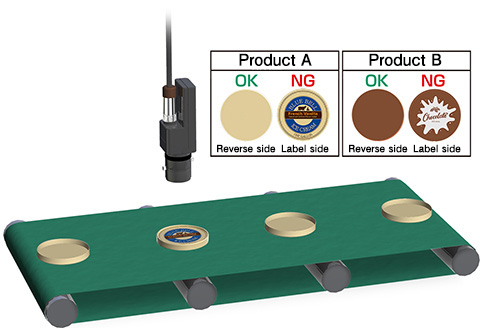

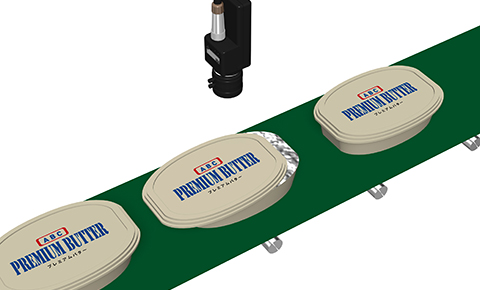

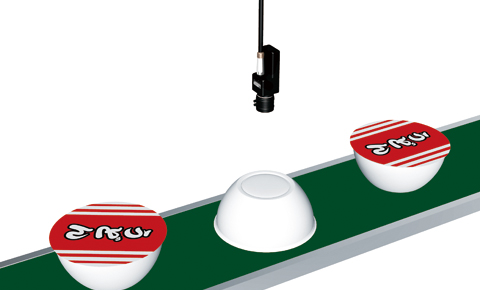

Ice Cream Container Lid Orientation Detection

With the MVS-PM-R color pattern matching vision sensor, the contamination matching mode allows for inspection of the lid orientation of cup-type ice cream containers.

By setting the reverse side as OK and the label side as NG, the MVS-PM-R is able to inspect for package illustrations on the surface for accurate detection of the lid orientation. The contamination matching mode also checks for patterns rather than just differences in color.

This means inspection can be performed without the need to reconfigure camera settings even if the product type changes.

Model: Color pattern matching camera MVS-PM-R Series

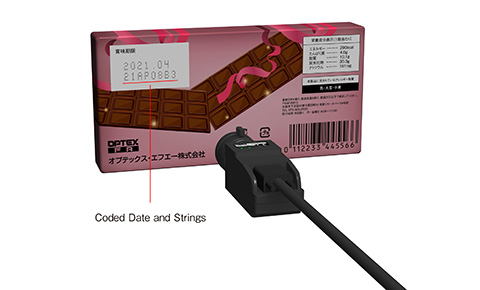

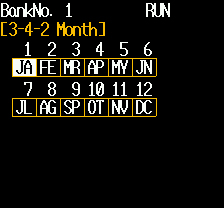

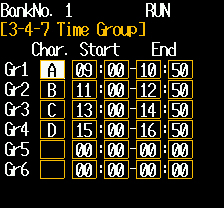

Recognizing coded date and time in the string

The OCR Vision Sensor, MVS-OCR2, checks an encoded date and time in a string, in addition to an expiration date.

A string for quality control including date and time can be recognized by automatic update using the calendar function.

Change of date or time to be recognized from production schedule requires no change in camera settings.

Setting example

| Printed string: | 21 | AP | 08 | B | 3 | ||||

|---|---|---|---|---|---|---|---|---|---|

| YEAR | + | MONTH | + | DAY | + | TIME ZONE | + | MACHINE NO. |

-

MONTH TABLE SETTING

If the string is "AP", it will be recognized as April.

-

TIME ZONE TABLE SETTING

If the string is "B", it will be recognized as a time zone from 11:00 to 12:50.

Model: Color OCR Camera Unit MVS-OCR2 Series

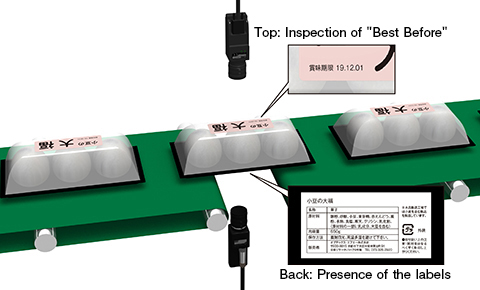

Presence of label on back side and print inspection of expiration date

MVS-PM-R of the pattern matching camera checks the presence of the back side label, and inspects the expiration date on the label with the OCR camera MVS-OCR2.

The controller MVS-DN-E can connect up to three cameras.

Since only one controller is required, it is possible to construct an inspection system with low cost.

Model: Color Pattern Matching Camera Unit MVS-PM-R Series

Model: Color OCR Camera Unit MVS-OCR2 Series

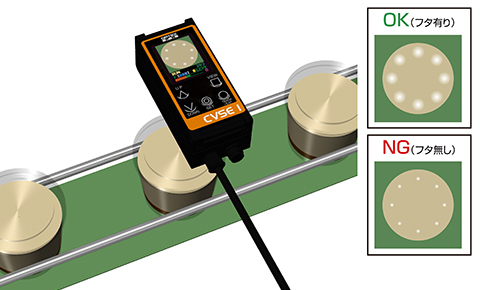

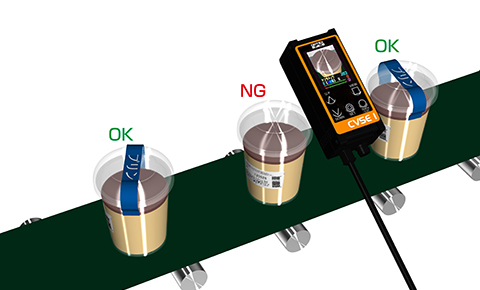

Presence of Transparent Lids

The CVSE1 easy color area sensor can be used for verifying the presence of lids on transparent containers such as for pudding.

Although detection of a transparent lid is generally difficult, installing the CVSE1 parallel to the lid and ensuring specular reflection makes detection possible by using the reflection of the built-in light source.

This ensures stable detection on production lines.

Model: Simple & Easy Setup Color Area Sensor CVSE1-RA Series

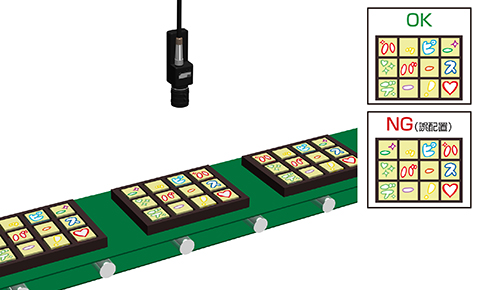

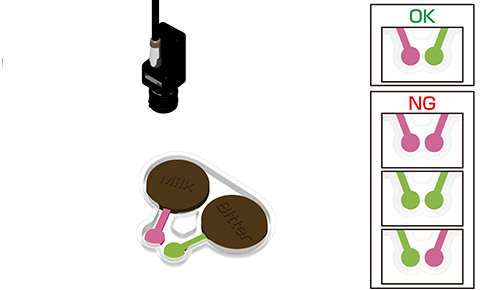

Chocolate arrangement monitoring

The MVS-PM-R pattern matching vision sensor makes it possible to check whether chocolates have been placed correctly.

The color-tone inspection function enables detection even if packaging contrast is low, as with photo prints. Moreover, the ability to set up to 16 inspection windows means detection results can be provided for each individual inspection window.

Model: Color pattern matching camera MVS-PM-R Series

Complex inspections of packages and marking

The MVS-OCR2 character recognition camera enables inspection of printed expiration dates, and the MVS-PM-R pattern matching camera enables inspections of contents and packaging errors.

Connecting these two cameras using the MVS-DN-E controller makes it possible to configure an AND circuit within the controller. This allows for inspections of poorly printed text and packaging errors without the need to organize sequences using a PLC.

Model: Color Pattern Matching Camera Unit MVS-PM-R Series

Model: Color OCR Camera Unit MVS-OCR2 Series

Character recognition in narrow space

Checking shelf life printed on the packages in small packaging machine by character recognition feature of the OCR vision sensor MVS-OCR2.

By attaching the 90 ° side view mirror to the tip of the lens, it is possible to install to a narrow space between the packaging films.

It realizes to install on a machine that could not install the camera due to space problem.

Model: Character recognition camera MVS-OCR2 Series

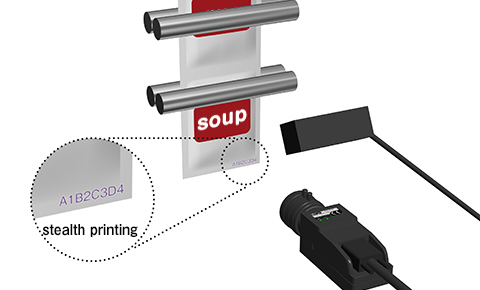

Checking existence of stealth printing

OCR vision sensor MVS-OCR2 can check existence of stealth invisible printing on packages.

The stealth ink used for those invisible printings that can be visible when exposed to ultraviolet lighting OPDB series. The combination with MVS-OCR2 and ultraviolet lighting OPDB series makes it possible checking existence of stealth invisible printing which is not required for consumers.

Model: Character recognition camera MVS-OCR2 Series

Detecting existence of the label on the cap

Detecting existence of the label on the cap by easy all in one vision sensor CVSE1-RA.

Its color resolution is 15,000 colors and depth of focus is long so setup is very simple and easy and detects colors correctly even if the conveyer bounces.

Model: Simple & Easy setup Color area sensor CVSE1-RA Series

Detecting deviation of the cap

Detecting deviation of the cap by color pattern matching camera MVS-PM-R.

When the cap is deviated, the camera will capture the aluminum seal and detect deviation of the cap. "Differential" function of MVS-PM-R will be able to detect the seal even if contrast between the cap and the seal is low.

Model: Color pattern matching camera MVS-PM-R Series

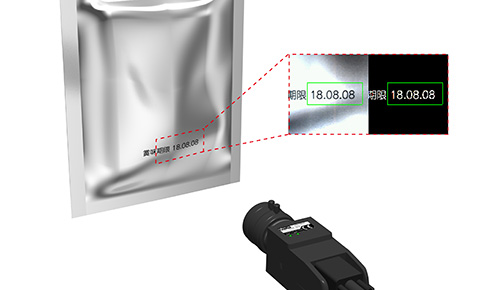

Print inspection on glossy surface

Print inspection on glossy surface like aluminum vapor deposition film by character recognition camera MVS-OCR2.

Even if printed characters on glossy material, MVS-OCR2 will be able to detect characters stably.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

Detecting package not sealed

Detecting if sealing is done correctly or not by color pattern matching camera MVS-PM-R.

"Differential" function of MVS-PM-R will be able to detect sealed or not sealed on top part of the package by checking grooves by sealing even if the contrast is low.

Model: Color pattern matching vision sensor MVS-PM-R Series

Checking shelf life and wrong box

Checking shelf life and wrongly made box by print inspection camera MVS-OCR2 and pattern matching camera MVS-PM-R.

Up to 3 cameras can be connected and controlled by one controller that reduces total cost of investment and make system configuration simple.

Model: Color pattern matching vision sensor MVS-PM-R Series

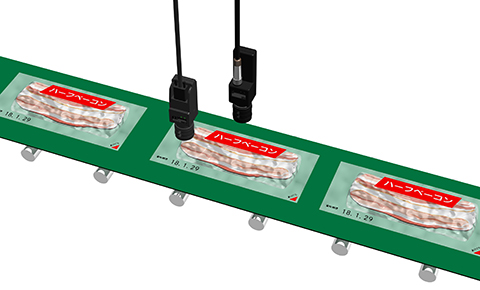

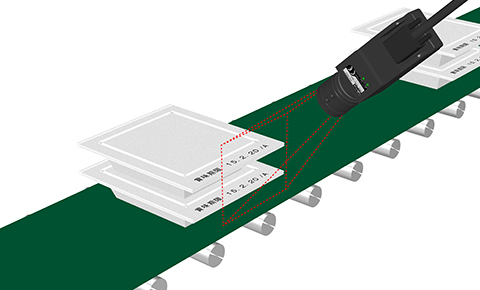

Print inspection of multiple packages at one time

Inspection of shelf life on multiple packages at one time by print inspection camera MVS-OCR2.

MVS-OCR2 can inspect up to 4 inspection window at one time. Narrow the iris of the lens so that the depth of focus get longer. Then, it can get clear image of multiple packages in FOV even if the distance of the object is different.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

Character recognition and counting character number at one time

By counting function of MVS-OCR2 (Character recognition vision sensor), existence of Kanji character can be detected.

By separating printed part into two part, one is Kanji part and another is numeric part, assigning inspection window for each part then set counting character number function for Kanji part and character recognition function for numeric part. Two part of the printing can be inspected at one time in this way.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

Character recognition of laser marker printing

Character recognition vision sensor MVS-OCR2 has 8 times bigger resolution than conventional model so it can recognize printing by laser marking even if the line is very narrow.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

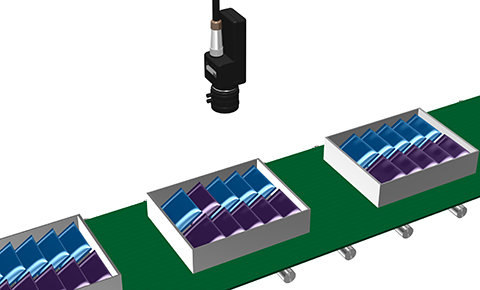

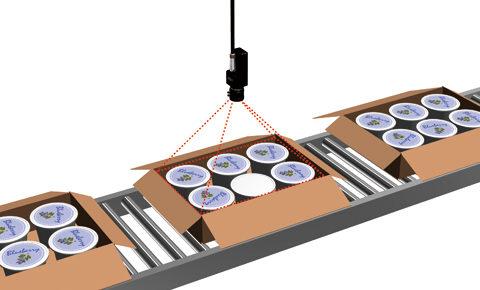

Checking position of individual packaging in the box

Color pattern matching camera MVS-PM-R can have up to 16 inspection window so each individual packaging can be checked if it's correct one or not.

Model: Color pattern matching vision sensor MVS-PM-R Series

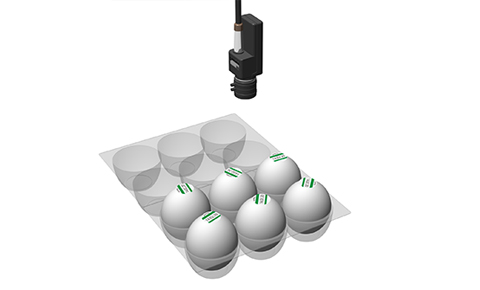

Checking existence of label on the eggs

By using "Stain area" function of MVS-PM-R, it can detect small labels even if its color is changed.

Model: Color pattern matching vision sensor MVS-PM-R Series

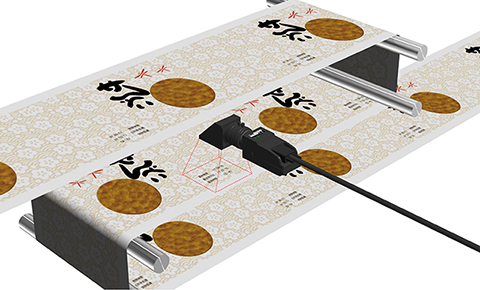

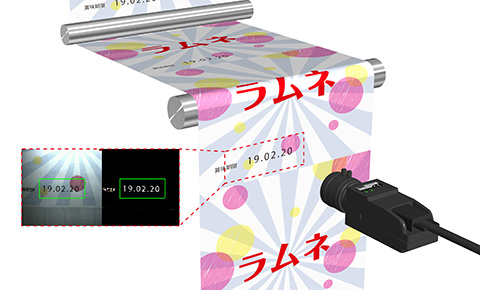

Character recognition of print on colored pattern

MVS-OCR2 can recognize characters printed on colored pattern by recognizing color of the characters stably.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

Print inspection of individual packages at deviated position on the conveyer

Because of high resolution of MVS-OCR2 camera, 8 times better than conventional model, it can have wide FOV so it can recognize characters printed on individual packaging at deviated position on the conveyer.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

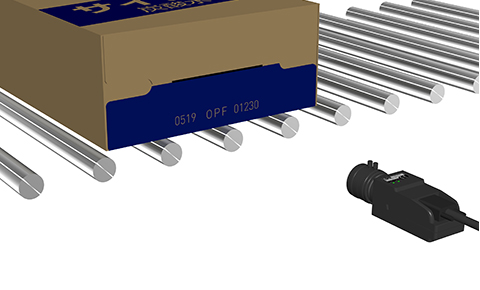

Print inspection of carton box (wide FOV)

Print inspection of production date and shelf life printed on the carton box at a time is possible because MVS-OCR2 can set wide FOV (Field Of View) thanks to its mega pixel image sensor.

You don't have to invest for two cameras so it's cost effective.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

Checking combination of two chocolate sticks

Checking if two different colored stick is aligned at correct position or not by MVS-PM-R. MVS-PM-R can have up to 16 inspection window so setup inspection window at the part you would like to check the color then it can check multiple parts of the image at a one time.

Model: Color pattern matching vision sensor MVS-PM-R Series

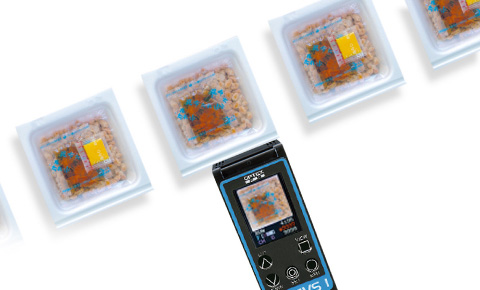

Checking existence of small packages for source and mustard in a package

CVS1 series can detect specific color area and its setup is very easy and simple.

Model: Color area sensor CVS1-N20-RA

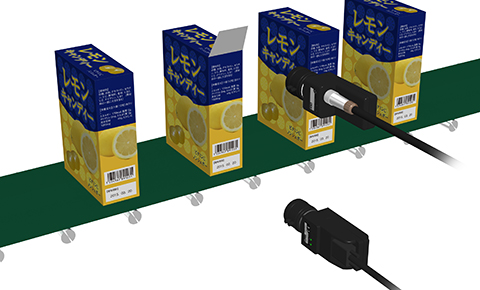

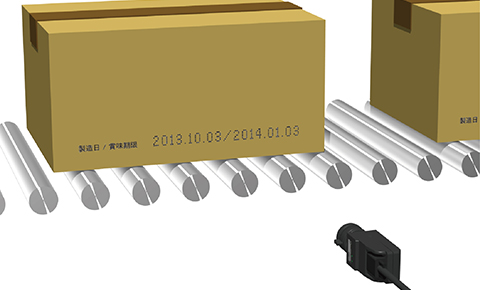

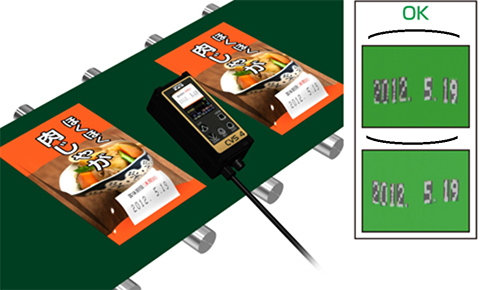

Checking of Expiration Dates on Cartons

Character recognition cameras can be used to check expiration dates printed on cartons using PC coders.

Judgments based on the number of characters (Character Count function) are effective when printing is uneven.

Model: Color OCR Camera Unit MVS-OCR2 Series

Checking position of cap on container

Checking position of cap on the container before fixing stage by detecting color of cap part of the container.

Model: Color pattern matching camera MVS-PM-R Series

Checking if the spout part is sitting correctly or not in the cap

Checking the shape and color of spout part in the cap and position of it by "contour" and "color area" function of MVS-PM-R.

Model: Color pattern matching camera MVS-PM-R Series

Checking side and direction of the box

Checking side and direction by checking position of printed mark on the box. MVS-PM-R can detect shape and color so it can check if the mark is correct or not.

Model: Color pattern matching camera MVS-PM-R Series

Print inspection of gum or candy

Checking characters printed on the gums or candies by CVS4-R.

It has calendar and timer built-in so it can check date code over night continuously.

Model: Character recognition vision sensor CVS4-R Series

Checking shape of "Tempura" for instant noodle

Shape of "Tempura" can be checked by MVS-PM-R utilizing its function "color shape" or "contour".

Model: Color pattern matching camera MVS-PM-R Series

Print inspection on rice cake package and checking existence of antioxidant in the package

Print inspection of shelf life by MVS-OCR2 and checking existence of antioxidant in the package by MVS-PM-R.

The controller MVS-DN can control up to 3 cameras so you don't have to have multiple controller in this case.

Either wrong printing nor missing antioxidant will be rejected by single output from the controller.

Model: Mega pixel character recognition camera MVS-OCR2 Series

Print inspection on two surface of the can

Print inspection on the shelf life printed on top and print inspection on the label attached on the side of the can at one time by two MVS-OCR2.

The controller MVS-DN can control up to 3 cameras so you don't have to have multiple controller in this case.

Wrong printing on the shelf life or on the label at side of the can will be rejected by single output from the controller.

Model: Mega pixel character recognition camera MVS-OCR2 Series

Print inspection on packages of source on 3 lines

Print inspection on the shelf life on 3 production lines can be done by 3 MVS-OCR2.

The controller MVS-DN can control up to 3 cameras so you don't have to have multiple controller and reduce cost in this case.

Model: Mega pixel character recognition camera MVS-OCR2 Series

Checking existence of source package on chilled pizza

Checking existence of source package on chilled pizza utilizing "color area" function of MVS-PM-R.

The color of the source package might change depends on the temperature though, "dark compensation" function will stabilize detecting color of the package and help stable detection of the source package.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of perforation

Checking existence of perforation by MVS-PM-R.

Utilizing backlight to make perforation visible by leakage of the light through the perforation, the color pattern matching camera MVS-PM-R will be able to detect perforation.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of fin on the mini-bottle for soy source

Detecting fin on the mini-bottle for soy source by MVS-PM-R.

"contour" function of MVS-PM-R will be able to detect small fin on the mini-bottle for soy source and prevents outflow of wrong bottle to next process.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of multiple label at one time

MVS-PM-R can have up to 16 inspection windows so it can assign inspection window for each label. It can output result of each inspection window so you will be able to know which label is missing.

Model: Color pattern matching camera MVS-PM-R Series

Checking side of package of instant noodle

Checking if the package is sitting on the conveyer correctly or not by MVS-PM-R.

Using "color area" function, it can detect correct side of the package. It can prevent outflow of upside down package to next process.

Model: Color pattern matching camera MVS-PM-R Series

Character recognition only date part

Character recognition vision sensor CVS4-R has "Character Re-scan" function so it can skip Kanji characters that to be skipped when checking date code only.

Model: Character recognition vision sensor CVS4-R Series

Character recognition of printing on the surface not even

Character recognition of printing on the boil-in-the-bag food package which is not always flat.

CVS4-R has original recognition algorism that enables recognition of characters on the surface which is not even.

Model: Character recognition vision sensor CVS4-R Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Others