Vision Sensors

Chemical/Cosmetics

- Print inspection for invisible ink printing

- Print inspection on low contrast printing

- Checking position of sealing tape

- Checking existence of description of the medicine

- Checking position of sealing tape

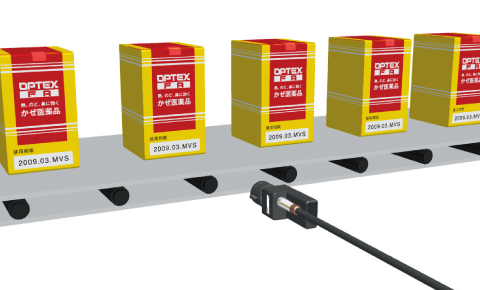

- Print inspection on the individual package for chemical

- Checking amount of hot-melt glue

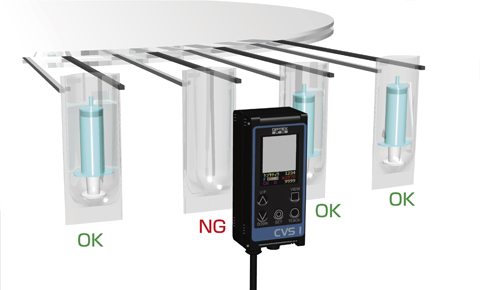

- Checking position of syringe

- Checking existence of the cap of the needle for syringe

- Checking existence of sealing tape and certificate label

- Checking existence of silica gel at the bottom of the bottle

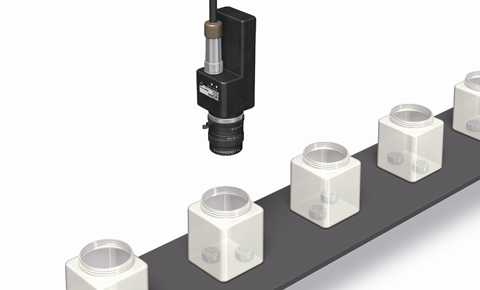

- Checking filling level of internal material in the bottle

- Checking existence of measure cap

- Checking direction of the individual package by checking printed characters

- Checking contents of medical kit

- Checking existence of printed character at bottom of ampoule container

- Checking existence of sealing tape

- Checking existence of notice flier

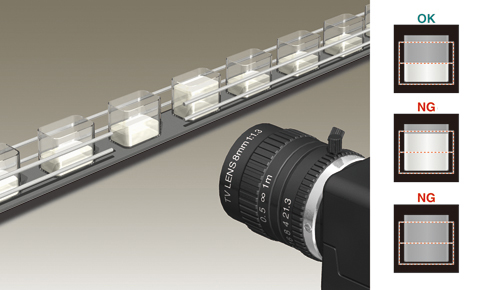

- Detecting extrusion of description paper from the package

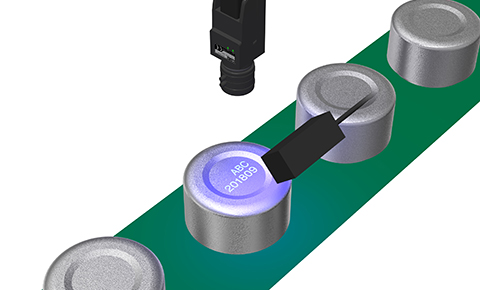

Print inspection for invisible ink printing

Print inspection for invisible fluorescent ink printing is possible utilizing ultra-violet LED lighting and mega pixel character recognition vision sensor MVS-OCR2.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

Print inspection on low contrast printing

Print inspection on low contrast printing for example black ink on dark blue base is possible by MVS-OCR2.

By high ability of extraction of colors on MVS-OCR2 enables print inspection on low contrast printing.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

Checking position of sealing tape

MVS-PM-R can have up to 16 inspection windows so by setting inspection windows at the sealing tape position and some other position the sealing tape would deviated to, it can check if the sealing tape is at the correct position or not.

Model: Color pattern matching vision sensor MVS-PM-R Series

Checking existence of description of the medicine

Because FOV of CVSE1-RA series is wide enough, it can check existence of description of the medicine stably even if the position of the description is deviated.

Model: Color area vision sensor CVSE1-N20-RA

Checking position of sealing tape

Because FOV of CVS1 series is wide enough, it can check existence of the sealing tape not only at side position but also at top side.

Model: Color area vision sensor CVS1-N20-RA

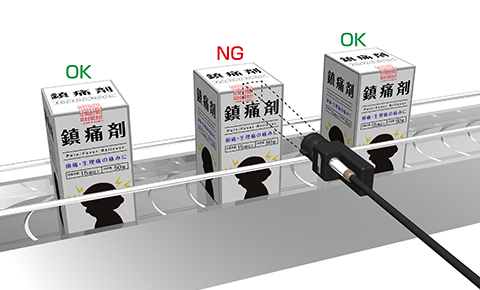

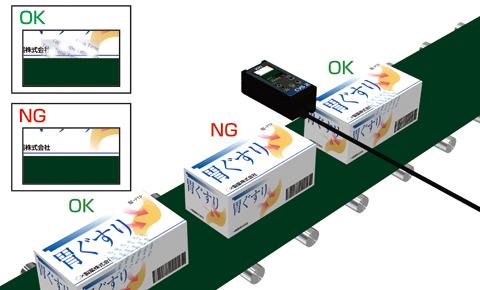

Print inspection on the individual package for chemical

MVS series can store NG images in the controller so you can check why it's rejected later.

Model: Mega pixel character recognition vision sensor MVS-OCR2 Series

Checking amount of hot-melt glue

MVS-PM-R can check amount of hot-melt glue supplied on the box by checking area of the hot-melt by "color area" function.

Model: Color pattern matching camera MVS-PM-R Series

Checking position of syringe

Checking if the position of the syringe is correct or not by checking color area in the transparent bag.

If the syringe is not in the bag completely, CVS1-RA will be able to detect less color area of the syringe and reject it.

Model: Color area sensor CVS1-RA Series

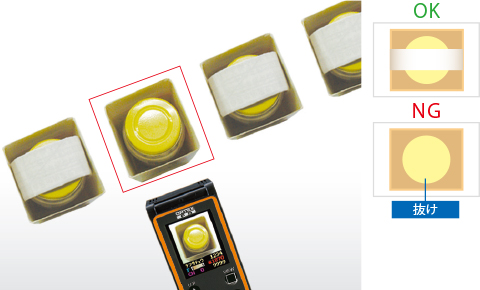

Checking existence of the cap of the needle for syringe

CVS1-RA will be able to detect the cap as white area so it can check existence of the cap of the needle.

The FOV is wide enough so it can detect the cap even if its position deviates.

Model: Color area sensor CVS1-RA Series

Checking existence of sealing tape and certificate label

MVS-PM-R will be able to detect existence of the sealing tape and the certificate label easily without affection from color pattern of the box by teaching without those tapes.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of silica gel at the bottom of the bottle

By checking color area of the silica gel at the bottom of the bottle, MVS-PM-R can check amount of the silica gel even if the silica gel position at the bottom of the bottle is not stable.

Model: Color pattern matching camera MVS-PM-R Series

Checking filling level of internal material in the bottle

By checking color area of the material in the transparent bottle, MVS-PM-R can check amount of the material filled in the bottle.

It can reject less material or over filled by setting threshold.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of measure cap

Measure cap position may deviate so simple photoelectric sensor can't detect the measure cap stably. Even if its position is deviated, CVS2-RA which has wide FOV can detect the measure cap stably.

Model: Pattern matching and color area sensor CVS2-RA Series

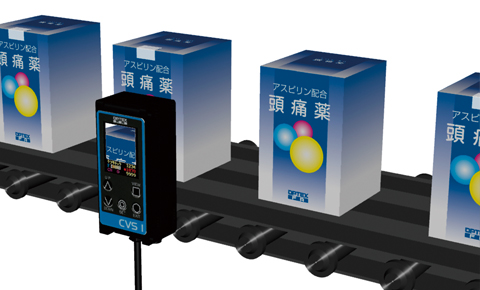

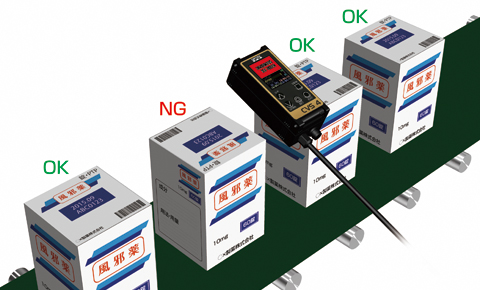

Checking direction of the individual package by checking printed characters

CVS4-R can check if the date code is correct and also it can count character number of lot number. By checking printed characters, it can check if the direction of the box is correct or not.

Model: Character recognition vision sensor CVS4-R Series

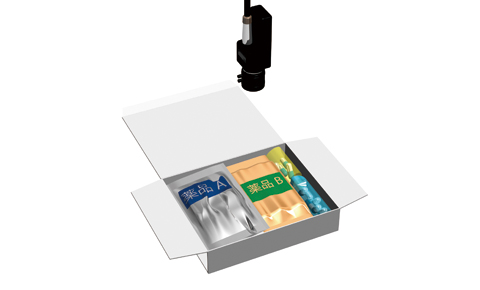

Checking contents of medical kit

Checking contents of testing kit of virus infection by MVS-PM-R.

Up to 16 inspection windows are available so you can check multiple parts of the contents of the testing kit at one time. Inspection function can be set for each inspection window individually.

It can output inspection result for each window.

Model: Color pattern matching vision sensor MVS-PM-R Series

Checking existence of printed character at bottom of ampoule container

Existence of characters printed at bottom of ampoule container can be checked by MVS-PM-R.

"stain area" function can be utilized for this application then, low contrast printing can be detected stably.

Model: Color pattern matching vision sensor MVS-PM-R Series

Checking existence of sealing tape

Checking existence of sealing tape on the package by CVS2-RA.

Normally, it is detected by color difference though, if color difference between the tape and the package is small, you can utilize reflectivity difference of them.

Model: Pattern matching & color area sensor CVS2-RA Series

Checking existence of notice flier

Checking existence of notice flier besides of the description paper by CVS2-RA.

Photoelectric sensor won't be able to detect notice flier stably because of the height deviation of the blister package of pills though, CVS2-RA with deep focal length will be able to detect the color of the notice flier stably.

Model: Pattern matching & color area sensor CVS2-RA Series

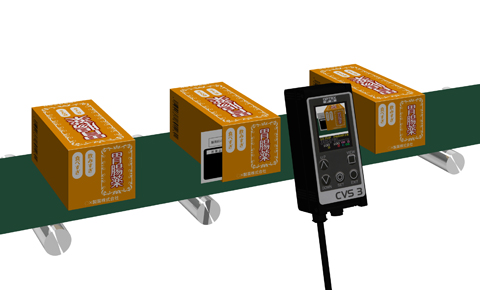

Detecting extrusion of description paper from the package

Detecting extrusion of description paper from the package by edge detection vision sensor CVS3-RA.

CVS3-RA is all in one including camera, controller and LCD monitor so you don't have to invest for expensive machine vision and start up simply with.

Model: Edge detection vision sensor CVS3-RA Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Others