Vision Sensors

Electric

- Dry Cell Electrode Inspection

- Checking existence of glue on the frame

- Positioning of PWB

- Checking lighting of LED and position

- Checking existence of packaging film for CD

- Checking color order of the wire harness

- Checking existence of relay on the assembly module

- Checking shape of the terminal

- Checking display of the LCD panel

- Checking part type by its shape

- Checking connector pins

- Print inspection on the molded plastic

- Checking existence of characters on metal surface

- Checking existence of screw locking glue on the motor shaft

- Checking parts direction on the switch assembly module

- Checking lighting of each part of 7 segment display

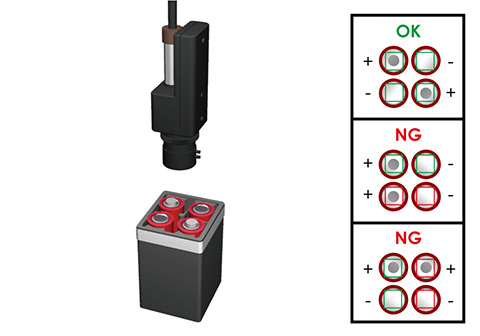

Dry Cell Electrode Inspection

The contamination matching mode of the MVS-PM-R color pattern matching vision sensor facilitates inspection of battery insertion directions.

Inspection windows can be set to display each of the positive and negative poles of four batteries.

Positive poles cast a shadow on the image from the shape of the pole’s protrusion, so setting a threshold for the area ratio of the black part of the shadow makes it possible to determine whether the batteries are inserted correctly in each inspection window.

Model: Color pattern matching camera MVS-PM-R Series

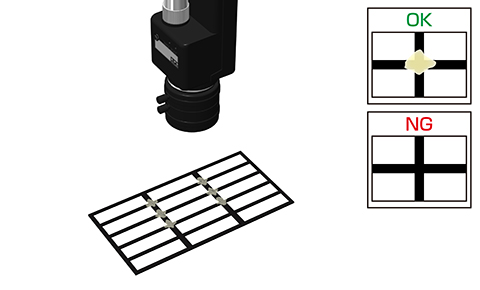

Checking existence of glue on the frame

Checking existence of glue on the frame by MVS-PM-R.

It can have up to 16 inspection windows so you can check existence of glue at up to 16 part of the frame at least at one time. Teach without glue and reverse the output logic so it detects NG when there is no glue on the frame.

Model: Color pattern matching camera MVS-PM-R Series

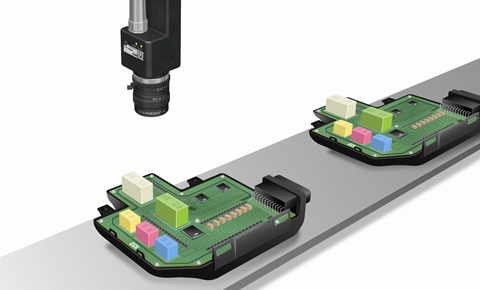

Positioning of PWB

Positioning of PWB by measurement camera MVS-EM-R.

Measuring position PWB edge from the edge of the FOV, it can get position of the PWB.

Model: Measurement camera MVS-EM-R Series

Checking lighting of LED and position

Checking LEDs if they are correctly lit and their position by CVS2 series.

It can check multiple LEDs in color and their position at one time.

Model: Pattern matching and Color area sensor CVS2-N20-RA

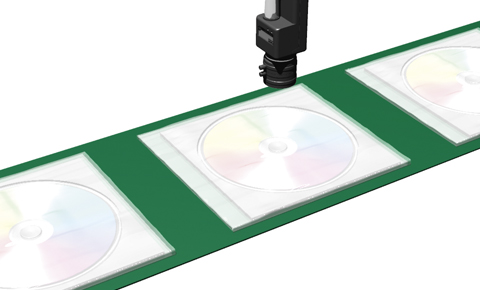

Checking existence of packaging film for CD

Checking existence of packaging film for CD by MVS-PM-R.

By aligning LED lighting so that the light reflects at the surface of the film and MVS-PM-R can get the light.

Model: Color pattern matching camera MVS-PM-R Series

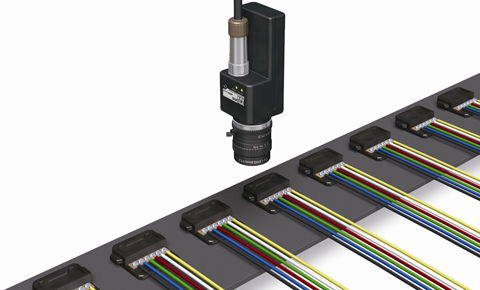

Checking color order of the wire harness

Checking color order of the wire harness by MVS-PM-R.

It can have up to 16 inspection windows so you can check up to 16 part of the wire harness. You can get inspection result of each inspection window from multiple outputs so you will know this wire is missing or wrong.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of relay on the assembly module

Checking if the relay is mounted at correct position or not on the assembly module by MVS-PM-R.

"color and shape" function will work fine for this application detecting color area at the position of the relay.

Model: Color pattern matching camera MVS-PM-R Series

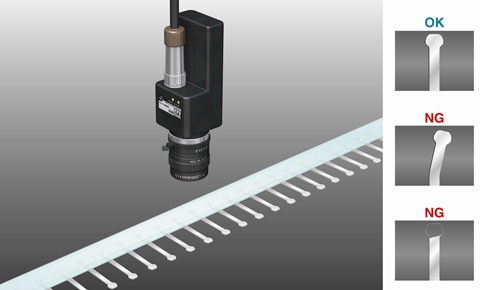

Checking shape of the terminal

Checking shape of the terminal by MVS-PM-R.

By its "contour" function, it can check shape of the terminal accurately and you can reject wrong shape or lack of part of it.

Model: Color pattern matching camera MVS-PM-R Series

Checking display of the LCD panel

Checking display of the LCD panel by MVS-PM-R.

By its "color and shape" function, it can check if the LCD panel displays correctly or not. It can have up to 16 inspection windows so you can detect small lack or malfunction of the LCD panel.

Model: Color pattern matching camera MVS-PM-R Series

Checking part type by its shape

Checking part type by its shape by MVS-PM-R.

"contour" function will be utilized for checking shape of the part and it can check small difference of the parts. "full color" function will be utilized for checking low contrast part so it can detect up side down.

Model: Color pattern matching camera MVS-PM-R Series

Checking connector pins

Checking if the connector pins exist or not and their shape by MVS-PM-R.

I can have up to 16 inspection window so you can check each pin in the connector housing at one time and you can get inspection result of each window separately.

Model: Color pattern matching camera MVS-PM-R Series

Print inspection on the molded plastic

Print inspection on the molded plastic by MVS-OCR2.

Not only rejecting NG parts but also you can get how the vision sensor recognized the printing by getting ASCII code of the characters from the vision sensor.

Mega pixel OCR vision sensor MVS-OCR2 Series

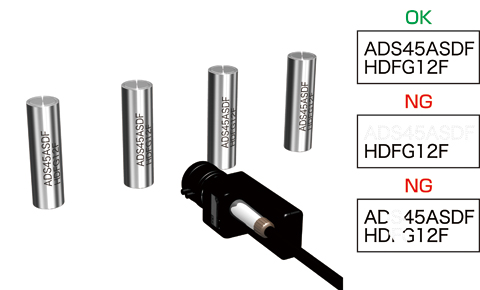

Checking existence of characters on metal surface

Checking existence of characters on metal surface by MVS-PM-R.

Generally, standard vision sensor won't be able to detect existence of characters on metal surface especially if it's hair-lined. MVS-PM-R's "stain" function detects existence of characters on metal surface stably.

Model: Color pattern matching camera MVS-PM-R Series

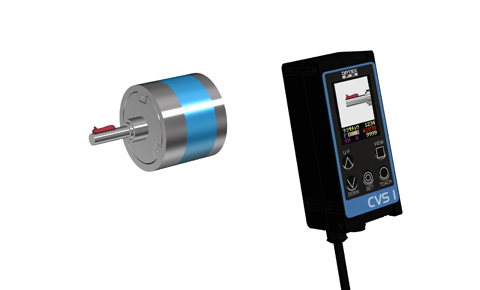

Checking existence of screw locking glue on the motor shaft

Checking existence of screw locking glue by CVS1-RA.

When the glue is on the motor shaft, the reflection changes so CVS1-RA can detect the glue even if the amount is small.

Model: Color area sensor CVS1-RA Series

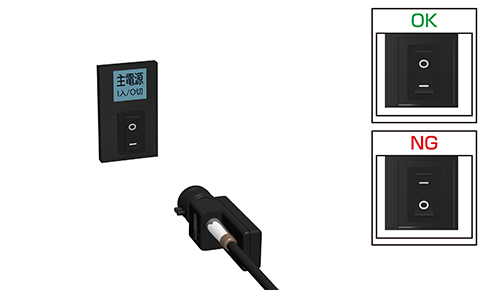

Checking parts direction on the switch assembly module

Checking parts direction on the switch assembly by MVS-PM-R.

"contour" function can detect contour of characteristic part of the switch parts on the assembly module.

Model: Color pattern matching camera MVS-PM-R Series

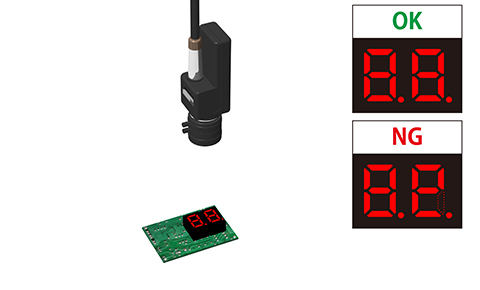

Checking lighting of each part of 7 segment display

Checking lighting of each part of 7 segment display by MVS-PM-R.

It can have up to 16 inspection windows so each part of 7 segment display can be inspected separately. You can get output for each inspection result separately so you will know which part is OK or NG.

Model: Color pattern matching camera MVS-PM-R Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Others