Vision Sensors

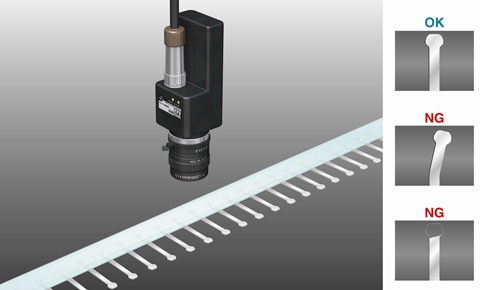

Shape and contour inspection

- Appearance inspection of sealing on medical equipments

- Detecting the hole clogged with machining scraps

- Checking evenness of plastic container

- Checking existence, color and alignment of the O-ring

- Checking appearance of the cap

- Checking if the needle is standing straight or not

- Checking shape of the part for air-bag

- Checking marking on the metal surface

- Checking size of cam

- Checking if the sealing rubber is sitting correctly or not

- Checking shape of assembled parts

- Checking shape of the screw head

- Checking number of grooves on the piston

- Checking existence of balls on the ball bearing

- Checking wrong parts fed mixed

- Checking if the hinge parts are assembled correctly or not

- Checking position of the bushing

- Checking existence of bad mark on the electronic parts

- Detecting deformation of the frame

- Checking existence of label on the plastic cover for home electric appliances

- Checking appearance of molded device package on the frame

- Checking appearance of screw parts

- Checking direction of LED light

- Checking if the button battery is sitting correctly or not

- Counting number of LED light lit in bar LED lighting

- Checking lighting of LED and position

- Checking color order of the wire harness

- Checking shape of the terminal

- Checking display of the LCD panel

- Checking connector pins

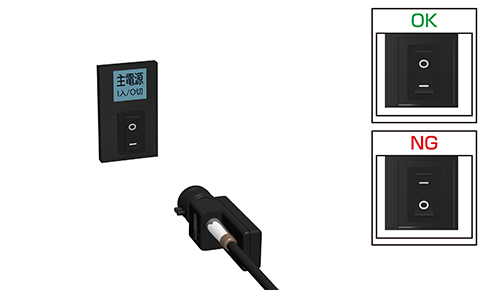

- Checking parts direction on the switch assembly module

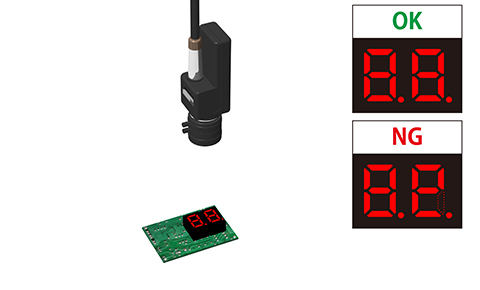

- Checking lighting of each part of 7 segment display

- Checking soldering on crystal oscillator

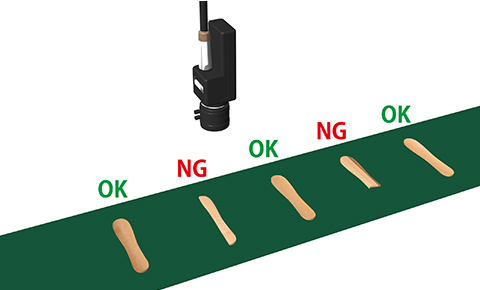

- Checking shape of the spoon

- Checking fault packaging on pillow packaging machine

- Detecting package that packed wrongly

- Checking contents of medical kit

- Checking if the sealing of package is done correctly or not

- Detecting package not sealed

- Checking combination of two chocolate sticks

- Checking shape of "Tempura" for instant noodle

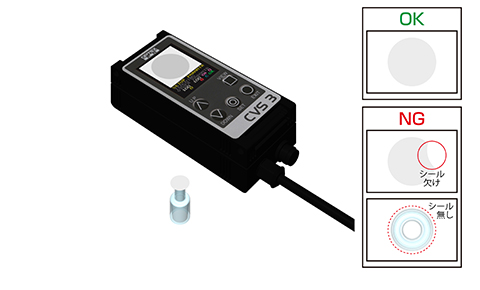

Appearance inspection of sealing on medical equipments

Appearance inspection of sealing on medical equipments by CVS3-RA.

It can check contour of sealing by detecting edge. You can reject missing and lack of sealing. CVS3-RA series is all in one structure so you don't have to worry about space for installation. You can save cost too..

Model: All in one edge sensor CVS3-RA Series

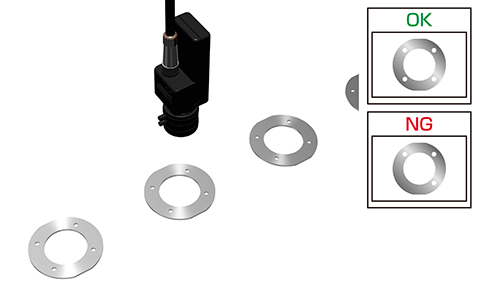

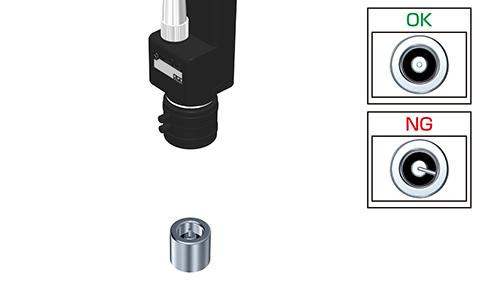

Detecting the hole clogged with machining scraps

Detecting the hole clogged with machining scraps by MVS-PM-R.

Its wide FOV helps inspection multiple holes utilizing inspection window available up to 16. You can get output that shows which hole is clogged.

Model: Color pattern matching camera MVS-PM-R Series

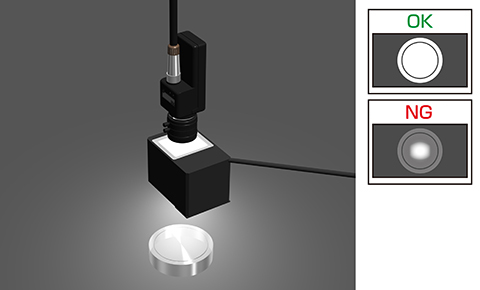

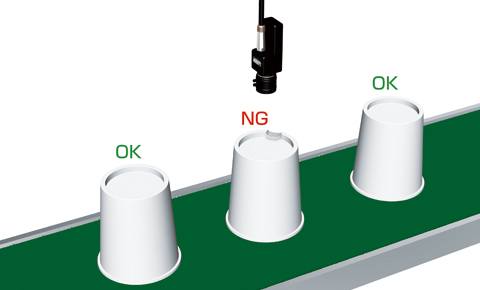

Checking evenness of plastic container

Checking evenness of plastic container by MVS-PM-R.

It can detect evenness of the surface of the plastic container utilizing coaxial LED lighting. When the surface is not even, the light will be reflected to various direction and the camera can detect difference.

OPTEX FA can recommend good combination of the vision sensor and LED lighting for the solution.

Model: Color pattern matching camera MVS-PM-R Series

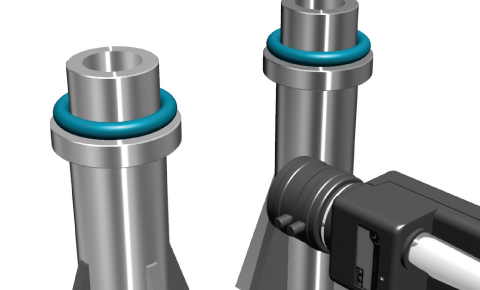

Checking existence, color and alignment of the O-ring

Checking existence, color and alignment of the O-ring by MVS-PM-R.

It can check not only color are but also shape or contour of the object. Then, it can detect overlapping of the object too.

Model: Color pattern matching camera MVS-PM-R Series

Checking appearance of the cap

Checking appearance of the cap by MVS-PM-R.

It can check appearance of the cap by MVS-PM-R utilizing its "contour" function precisely. This will help reducing cost of inspection very much.

Model: Color pattern matching camera MVS-PM-R Series

Checking if the needle is standing straight or not

Checking if the needle is standing straight or not by MVS-PM-R.

If the needle is bended, contour of the needle shows clear edge in the captured image so MVS-PM-R can detect it easily.

Model: Color pattern matching camera MVS-PM-R Series

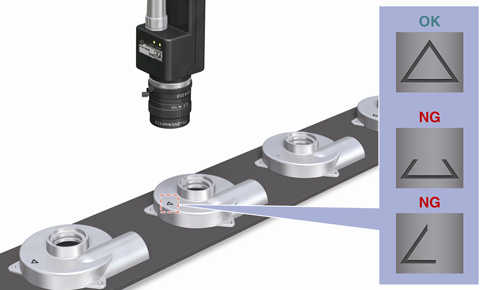

Checking shape of the part for air-bag

Checking shape of the part for air-bag by CVS3-RA.

The part was checked by 4 fiber sensor before though, the part has notch so sometimes the fiber sensor rejected correct one looking at the notch.

CVS3-RA can detect whole part in its FOV so you can check the part by only one CVS3-RA.

Model: Edge detect vision sensor CVS3-RA Series

Checking marking on the metal surface

Checking marking on the metal surface by MVS-PM-R.

With coaxial lighting, the marking will be detected easily because the surface of the metal is shiny and coaxial lighting will make the surface bright and the marking dark clearly.

Model: Color pattern matching camera MVS-PM-R Series

Checking size of cam

Checking size of cam by MVS-EM-R.

By "outer dimension" function, it can measure the size of the parts accurately.

I can also have 16 inspection window so various measurement can be done.

Model: Measurement camera MVS-EM-R Series

Checking if the sealing rubber is sitting correctly or not

Checking if the sealing rubber is sitting at correct position or not by CVS2 series.

It can detect sealing rubber by its color and check if the sealing rubber is sitting at correct position or not and also it can check the shape of the sealing rubber.

Model: Pattern matching & Color area sensor CVS2-N21-RA

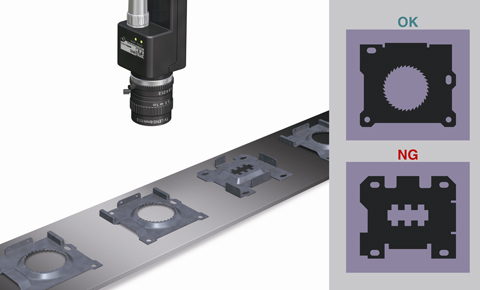

Checking shape of assembled parts

Checking shape of the assembled parts by CVS3 series.

It can detect contour by edge detecting function utilizing backlight.

Model: Edge sensor CVS3-N21-RA

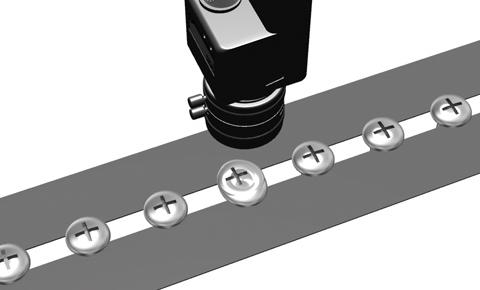

Checking shape of the screw head

Checking shape of the screw head by MVS-PM-R.

By checking contour of screw head, it can reject wrong or broken screw.

Model: Color pattern matching camera MVS-PM-R Series

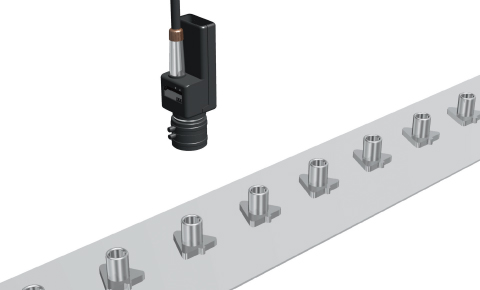

Checking number of grooves on the piston

Checking number of grooves on the piston by MVS-EM-R.

It can count number of grooves on the piston by "edge count" correctly. Just counting number means it doesn't need size calibration so it will be very easy inspection.

Model: Measurement camera MVS-EM-R Series

Checking existence of balls on the ball bearing

Checking existence of balls on the ball bearing by MVS-PM-R.

It can have up to 16 inspection windows so you can check existence of each ball on the ball bearing at one time.

Model: Color pattern matching camera MVS-PM-R Series

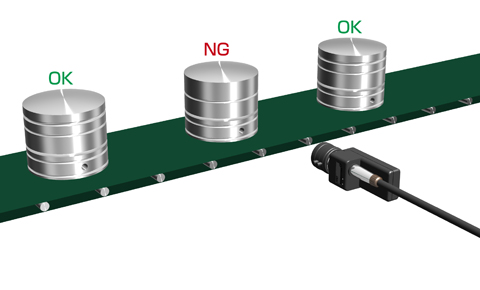

Checking wrong parts fed mixed

Checking wrong parts fed mixed by MVS-PM-R.

"contour" function will work fine for this application. It can detect the shape clearly and reject wrong parts efficiently.

Model: Color pattern matching camera MVS-PM-R Series

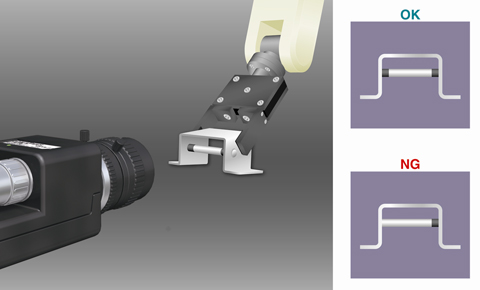

Checking if the hinge parts are assembled correctly or not

Checking if the hinge parts are assembled correctly or not by MVS-PM-R.

Setting 2 inspection windows at left and right side of the frame and pin so that it can detect if the pin is set correctly or not.

Model: Color pattern matching camera MVS-PM-R Series

Checking position of the bushing

Checking position of the bushing by CVS3-RA series.

Because it's all in one vision sensor, you don't have to install lighting, camera, monitor and controller separately so installation will be very simple.

It can detect shape and also deviation of bushing position by edge detection.

Model: All in one edge sensor CVS3-RA Series

Checking existence of bad mark on the electronic parts

Checking existence of bad mark on the electronic parts by CVS2-RA.

It can detect 2 colors at one time for example one color of the parts body and another of the lead of the parts.

Model: Pattern matching & color area sensor CVS2-N21-RA

Detecting deformation of the frame

Detecting deformation of the frame by MVS-EM-R.

When the frame deforms, the distance from edge to edge on the frame will be changed. MVS-EM-R can have up to 16 inspection window so you can measure 16 part of the frame at one time.

Model: Measurement camera MVS-EM-R Series

Checking existence of label on the plastic cover for home electric appliances

Checking existence of label on the plastic cover for home electric appliances by MVS-PM-R.

By checking color area of the label, it can detect existence of it. One controller can control up to 3 cameras so multiple inspection can be done by one controller.

Model: Color pattern matching camera MVS-PM-R Series

Checking appearance of molded device package on the frame

Checking appearance of molded device package on the frame by MVS-PM-R.

It can check contour of the object by "contour" function accurately and also it has masking function that neglect other part that doesn't need any inspection.

Model: Color pattern matching camera MVS-PM-R Series

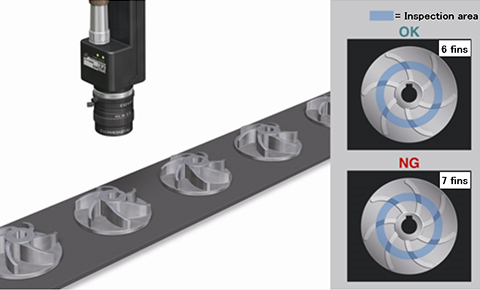

Checking appearance of screw parts

Checking appearance of screw parts by MVS-PM-R.

By detecting wrong parts, it can prevent wrong part fed into production line.

It can detect contour of the object by "contour" function accurately so any different part with wrong part with different number of fins can be rejected.

Masking function also will be utilized for efficient inspection.

Model: Color pattern matching camera MVS-PM-R Series

Checking direction of LED light

Checking direction of LED light by MVS-PM-R.

"color and shape" function of MVS-PM-R can detect shape of internal terminal in the LED light.

Model: Color pattern matching camera MVS-PM-R Series

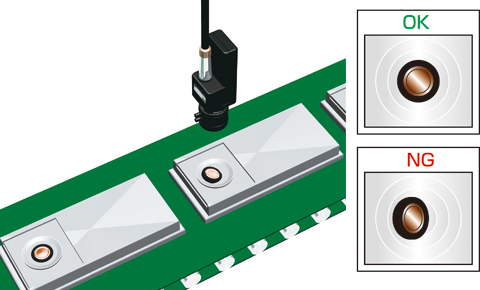

Checking if the button battery is sitting correctly or not

Checking if the button battery is sitting correctly in the remote controller or not by MVS-PM-R.

Detecting shape of the button battery and check if it's circle or not and also its position by pattern matching.

Model: Color pattern matching camera MVS-PM-R Series

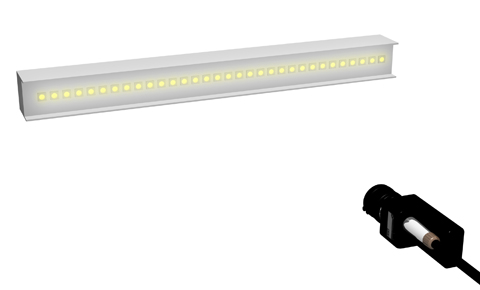

Counting number of LED light lit in bar LED lighting

Counting number of LED light lit in bar LED lighting by MVS-EM.

By its "edge count" function, it can count number of LED light.

Model: Measurement vision sensor MVS-EM-R Series

Checking lighting of LED and position

Checking LEDs if they are correctly lit and their position by CVS2 series.

It can check multiple LEDs in color and their position at one time.

Model: Pattern matching and Color area sensor CVS2-N20-RA

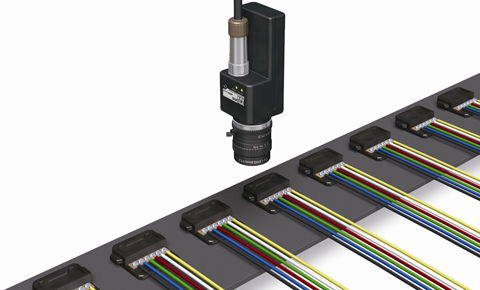

Checking color order of the wire harness

Checking color order of the wire harness by MVS-PM-R.

It can have up to 16 inspection windows so you can check up to 16 part of the wire harness. You can get inspection result of each inspection window from multiple outputs so you will know this wire is missing or wrong.

Model: Color pattern matching camera MVS-PM-R Series

Checking shape of the terminal

Checking shape of the terminal by MVS-PM-R.

By its "contour" function, it can check shape of the terminal accurately and you can reject wrong shape or lack of part of it.

Model: Color pattern matching camera MVS-PM-R Series

Checking display of the LCD panel

Checking display of the LCD panel by MVS-PM-R.

By its "color and shape" function, it can check if the LCD panel displays correctly or not. It can have up to 16 inspection windows so you can detect small lack or malfunction of the LCD panel.

Model: Color pattern matching camera MVS-PM-R Series

Checking connector pins

Checking if the connector pins exist or not and their shape by MVS-PM-R.

I can have up to 16 inspection window so you can check each pin in the connector housing at one time and you can get inspection result of each window separately.

Model: Color pattern matching camera MVS-PM-R Series

Checking parts direction on the switch assembly module

Checking parts direction on the switch assembly by MVS-PM-R.

"contour" function can detect contour of characteristic part of the switch parts on the assembly module.

Model: Color pattern matching camera MVS-PM-R Series

Checking lighting of each part of 7 segment display

Checking lighting of each part of 7 segment display by MVS-PM-R.

It can have up to 16 inspection windows so each part of 7 segment display can be inspected separately. You can get output for each inspection result separately so you will know which part is OK or NG.

Model: Color pattern matching camera MVS-PM-R Series

Checking soldering on crystal oscillator

![]()

Checking solder on crystal oscillator by MVS-PM-R.

It can setup up to 16 inspection windows so you can divide the target image into multiple part and check the amount of solder part in each inspection window which can improve accuracy of inspection.

Model: Color pattern matching camera MVS-PM-R Series

Checking shape of the spoon

Checking shape of the spoon by color pattern matching camera MVS-PM-R.

"color area" function will work fine to check shape of the spoon made with wood plate. It will be able to detect lack or clack on the spoon.

Model: Color pattern matching camera MVS-PM-R Series

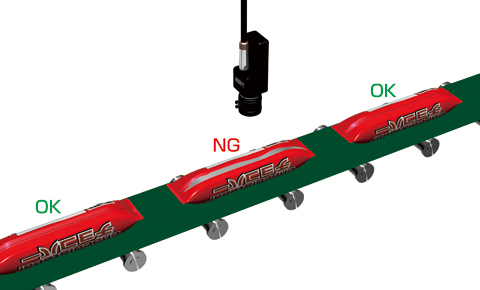

Checking fault packaging on pillow packaging machine

Checking fault package on pillow packaging machine by MVS-PM-R.

When the package sealing is done wrongly, it will show different color of the other side of the package. Color pattern matching camera MVS-PM-R will be able to detect it by "color area" function easily.

Model: Color pattern matching camera MVS-PM-R Series

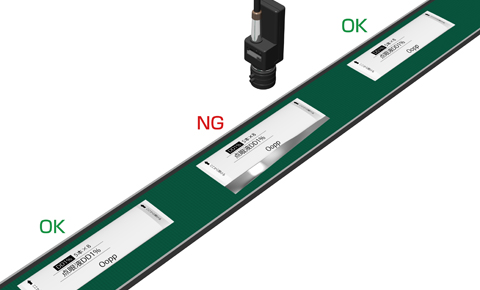

Detecting package that packed wrongly

Detecting package that packed wrongly by checking its shape and color by MVS-PM-R.

"color area" and "contour" function will be utilized for this application.

Model: Color pattern matching camera MVS-PM-R Series

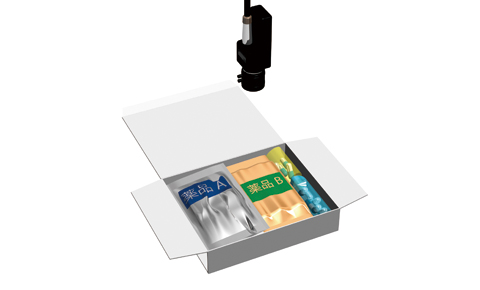

Checking contents of medical kit

Checking contents of testing kit of virus infection by MVS-PM-R.

Up to 16 inspection windows are available so you can check multiple parts of the contents of the testing kit at one time. Inspection function can be set for each inspection window individually.

It can output inspection result for each window.

Model: Color pattern matching vision sensor MVS-PM-R Series

Checking if the sealing of package is done correctly or not

When the sealing is not done correctly, the shape of the sealing part shows differently so pattern matching camera can detect it.

Model: Color pattern matching camera MVS-PM-R Series

Detecting package not sealed

Detecting if sealing is done correctly or not by color pattern matching camera MVS-PM-R.

"Differential" function of MVS-PM-R will be able to detect sealed or not sealed on top part of the package by checking grooves by sealing even if the contrast is low.

Model: Color pattern matching vision sensor MVS-PM-R Series

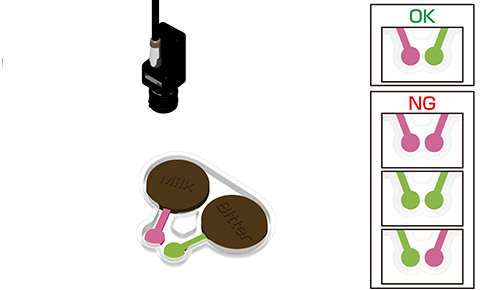

Checking combination of two chocolate sticks

Checking if two different colored stick is aligned at correct position or not by MVS-PM-R. MVS-PM-R can have up to 16 inspection window so setup inspection window at the part you would like to check the color then it can check multiple parts of the image at a one time.

Model: Color pattern matching vision sensor MVS-PM-R Series

Checking shape of "Tempura" for instant noodle

Shape of "Tempura" can be checked by MVS-PM-R utilizing its function "color shape" or "contour".

Model: Color pattern matching camera MVS-PM-R Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Other