Vision Sensors

Position inspection

- Checking the presence and position of bands on cardboard packaging

- Chocolate arrangement monitoring

- Positioning of PWB

- Measurement of position of glass edge

- Checking position of bar code label

- Checking deviation of the handle position of paper bag

- Checking position of sealing tape

- Checking position of syringe

- Detecting extrusion of description paper from the package

- Checking position of shrink label on the bottle

- Detecting deviation of the cap

- Checking position of cap on container

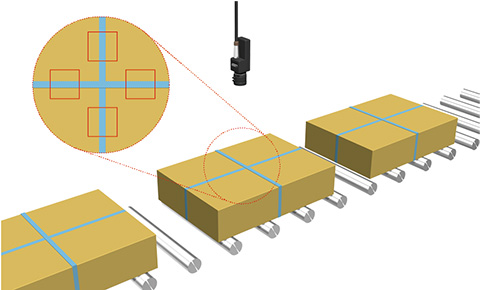

Checking the presence and position of bands on cardboard packaging

With the MVS-PM-R color pattern matching vision sensor, the color area mode allows for detection of packaging bands on cardboard boxes.

Setting inspection windows in four locations on the top, bottom, left, and right makes it possible to check whether the bands are in the correct positions both vertically and horizontally.

This means both presence checking and position checking are possible.

Model: Color pattern matching camera MVS-PM-R Series

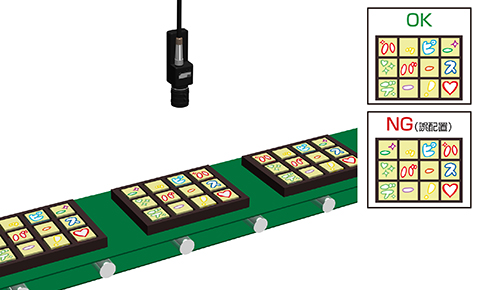

Chocolate arrangement monitoring

The MVS-PM-R pattern matching vision sensor makes it possible to check whether chocolates have been placed correctly.

The color-tone inspection function enables detection even if packaging contrast is low, as with photo prints. Moreover, the ability to set up to 16 inspection windows means detection results can be provided for each individual inspection window.

Model: Color pattern matching camera MVS-PM-R Series

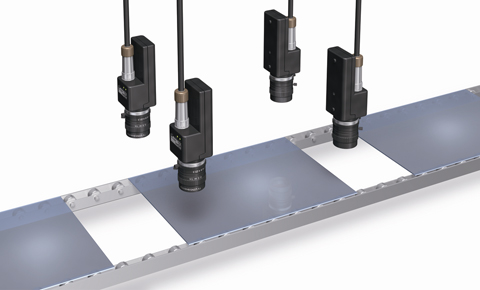

Positioning of PWB

Positioning of PWB by measurement camera MVS-EM-R.

Measuring position PWB edge from the edge of the FOV, it can get position of the PWB.

Model: Measurement camera MVS-EM-R Series

Measurement of position of glass edge

Measurement of position of glass edge by MVS-EM-R.

"edge position" function of MVS-EM-R will work fine to measure the position of glass edge. Utilizing multiple cameras, you can get size of the glass as well.

Model: Measurement camera MVS-EM-R Series

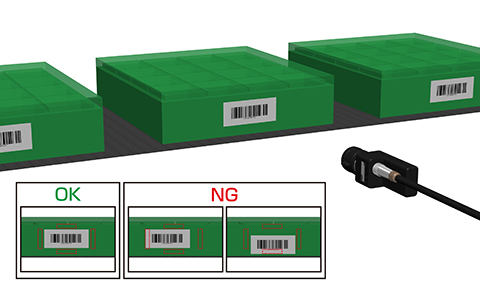

Checking position of bar code label

Checking position of bar code label by color pattern matching camera MVS-PM-R.

It can have up to 16 inspection windows so you can put multiple inspection windows to check if the label is at the correct position or not. It can output inspection result of each window so you will know which part the label is attached.

Model: Color pattern matching vision sensor MVS-PM-R Series

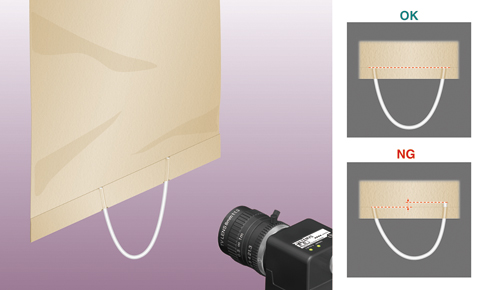

Checking deviation of the handle position of paper bag

Checking deviation of the handle position of the paper bag by measurement vision sensor MVS-EM-R.

It can have up to 16 inspection windows so position of each part can be checked at one time and also distance of those parts can be measured.

Model: Measurement vision sensor MVS-EM-R Series

Checking position of sealing tape

MVS-PM-R can have up to 16 inspection windows so by setting inspection windows at the sealing tape position and some other position the sealing tape would deviated to, it can check if the sealing tape is at the correct position or not.

Model: Color pattern matching vision sensor MVS-PM-R Series

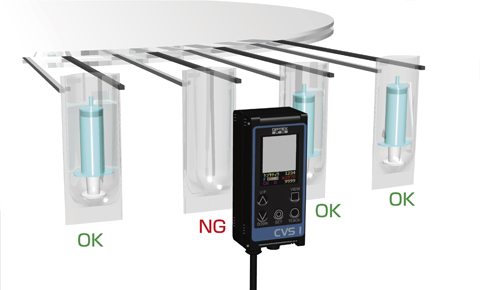

Checking position of syringe

Checking if the position of the syringe is correct or not by checking color area in the transparent bag.

If the syringe is not in the bag completely, CVS1-RA will be able to detect less color area of the syringe and reject it.

Model: Color area sensor CVS1-RA Series

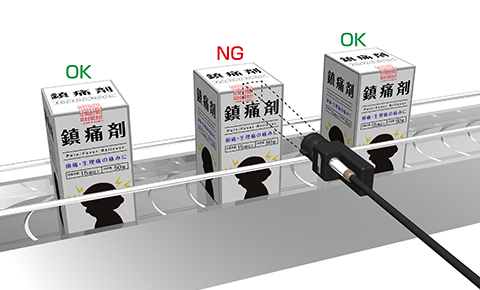

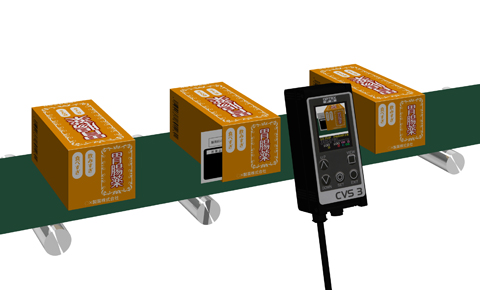

Detecting extrusion of description paper from the package

Detecting extrusion of description paper from the package by edge detection vision sensor CVS3-RA.

CVS3-RA is all in one including camera, controller and LCD monitor so you don't have to invest for expensive machine vision and start up simply with.

Model: Edge detection vision sensor CVS3-RA Series

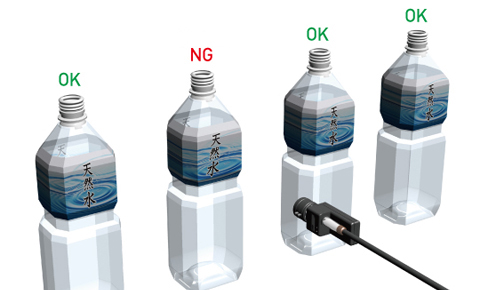

Checking position of shrink label on the bottle

Checking position of shrink label on the bottle by pattern matching camera MVS-PM-R.

"contour" function will work fine for this application.

Model: Color pattern matching camera MVS-PM-R Series

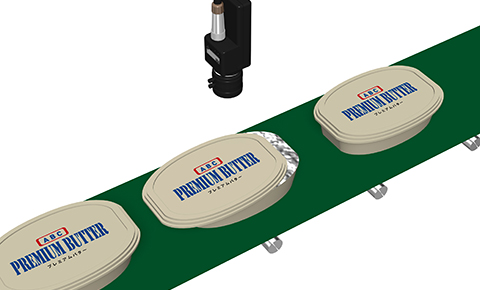

Detecting deviation of the cap

Detecting deviation of the cap by color pattern matching camera MVS-PM-R.

When the cap is deviated, the camera will capture the aluminum seal and detect deviation of the cap. "Differential" function of MVS-PM-R will be able to detect the seal even if contrast between the cap and the seal is low.

Model: Color pattern matching camera MVS-PM-R Series

Checking position of cap on container

Checking position of cap on the container before fixing stage by detecting color of cap part of the container.

Model: Color pattern matching camera MVS-PM-R Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Other