Vision Sensors

Automotive

- Checking direction of parts for automotive

- Checking existence of plastic joint parts on the frame

- Checking if the needle is standing straight or not

- Detecting wrong metal shaft in the production line

- Checking shape of the part for air-bag

- Checking amount of area of balance mark

- Checking color of coil spring

- Checking marking on the metal surface

- Checking marking (L: Left / R: Right) on the plastic parts

- Checking size of cam

- Detecting wrong parts at assembling line

- Checking if the sealing rubber is sitting correctly or not

- Checking if the parts are correct or not by inspecting characters

- Checking side of the cap at feeding process

- Checking shape of assembled parts

- Checking if the springs are correct or not

- Checking existence of LOCTITE

- Print inspection on the sun-roof glass plate

- Checking shape of the screw head

- Checking existence of grooves at inside of the parts

- Checking number of grooves on the piston

- Detecting wrong type axel pedal fed mixed in the process

- Checking side of round metal parts

- Detecting quenched or not and types by number of holes

- Checking existence of balls on the ball bearing

- Checking glue amount on the metal surface

- Checking wrong parts fed mixed

- Checking marking on the meter panel parts

- Checking if the hinge parts are assembled correctly or not

- Measurement of fan belt width

- Checking marking on the pipe

- Sorting mounting bush by color of marking

- Detecting wrong type metal plate fed mixed in the process

- Checking position of the bushing

- Detecting wrong type parts fed mixed in the process

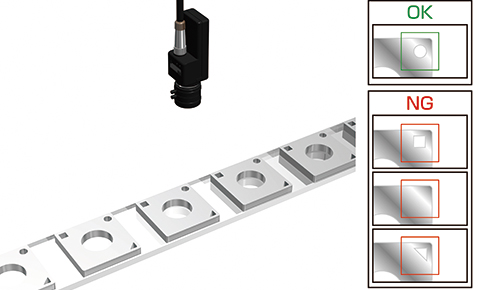

Checking direction of parts for automotive

Checking direction of parts for automotive by MVS-PM-R.

By checking multiple parts of the target object utilizing multiple inspection window that MVS-PM-R can have up to 16, it can detect direction of the parts.

Model: Color pattern matching camera MVS-PM-R Series

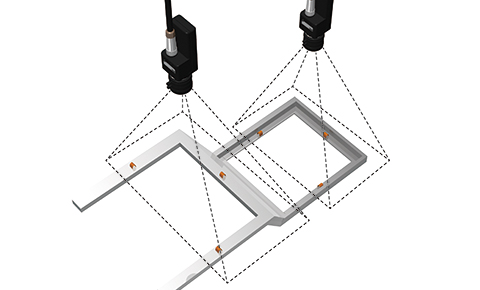

Checking existence of plastic joint parts on the frame

Checking existence of plastic joint parts on the frame by MVS-PM-R.

Since the controller MVS-DN-E can control up to 3 cameras at one time so wide area can be covered. MVS vision sensor series helps reducing cost of total system.

Model: Color pattern matching camera MVS-PM-R Series

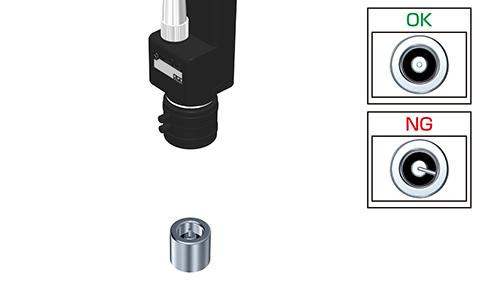

Checking if the needle is standing straight or not

Checking if the needle is standing straight or not by MVS-PM-R.

If the needle is bended, contour of the needle shows clear edge in the captured image so MVS-PM-R can detect it easily.

Model: Color pattern matching camera MVS-PM-R Series

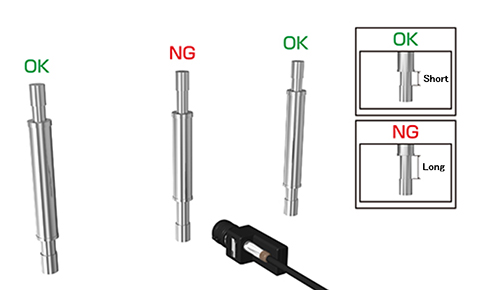

Detecting wrong metal shaft in the production line

Detecting wrong metal shaft in the production line by MVS-EM-R.

It can measure the length of end part of the metal shaft and detect if it's correct one or not.

Model: Measurement vision sensor MVS-EM-R Series

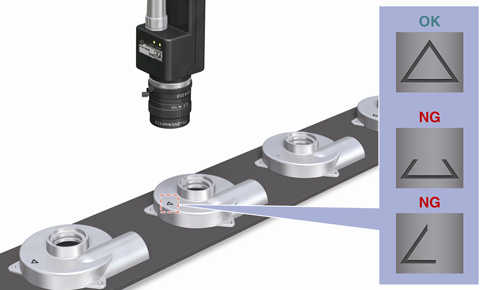

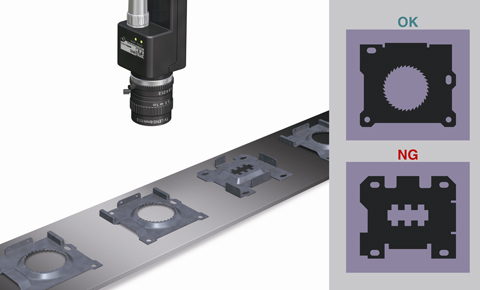

Checking shape of the part for air-bag

Checking shape of the part for air-bag by CVS3-RA.

The part was checked by 4 fiber sensor before though, the part has notch so sometimes the fiber sensor rejected correct one looking at the notch.

CVS3-RA can detect whole part in its FOV so you can check the part by only one CVS3-RA.

Model: Edge detect vision sensor CVS3-RA Series

Checking amount of area of balance mark

Checking amount of area of balance mark by MVS-PM-R.

You can save the result into PC by connecting through USB or Ethernet.

Model: Color pattern matching camera MVS-PM-R Series

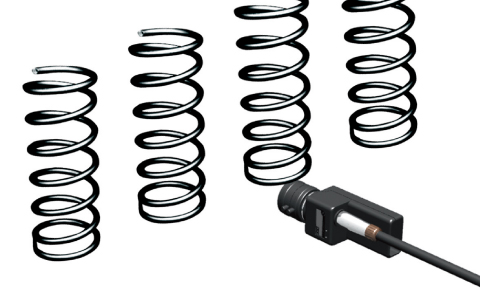

Checking color of coil spring

Checking color of coil spring by CVS1 series.

By detecting color of coil spring, it can define model number of the coil spring. CVS1 series has 16 banks so you can switch the bank depends on the model number.

Model: All in one color are sensor CVS1-N20-RA

Checking marking on the metal surface

Checking marking on the metal surface by MVS-PM-R.

With coaxial lighting, the marking will be detected easily because the surface of the metal is shiny and coaxial lighting will make the surface bright and the marking dark clearly.

Model: Color pattern matching camera MVS-PM-R Series

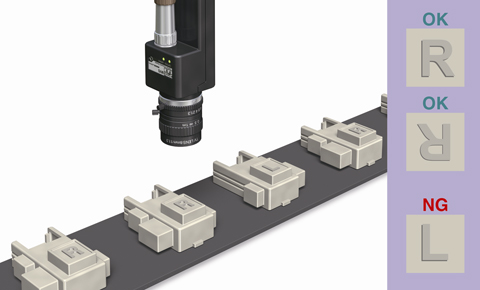

Checking marking (L: Left / R: Right) on the plastic parts

Checking marking (L: Left / R: Right) on the plastic parts by MVS-PM-R.

Even if the parts rotated, MVS-PM can detect the marking utilizing "rotate search" function.

Model: Color pattern matching camera MVS-PM-R Series

Checking size of cam

Checking size of cam by MVS-EM-R.

By "outer dimension" function, it can measure the size of the parts accurately.

I can also have 16 inspection window so various measurement can be done.

Model: Measurement camera MVS-EM-R Series

Detecting wrong parts at assembling line

Detecting wrong parts at assembling line by CVS2 series.

By checking color and shape of metal or plastic parts, it can detect if the parts are correct or not. It has masking function which will help inspection efficiency as well.

Model: Pattern matching & Color area sensor CVS2-N21-RA

Checking if the sealing rubber is sitting correctly or not

Checking if the sealing rubber is sitting at correct position or not by CVS2 series.

It can detect sealing rubber by its color and check if the sealing rubber is sitting at correct position or not and also it can check the shape of the sealing rubber.

Model: Pattern matching & Color area sensor CVS2-N21-RA

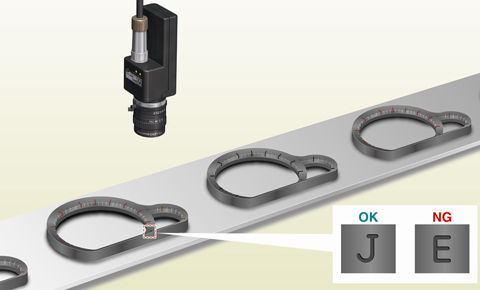

Checking if the parts are correct or not by inspecting characters

Checking if the parts are correct or not by inspecting characters by MVS-OCR2.

It has a function that output character code of first character. This can be utilized for sorting by type of the parts at next stage of the line.

Model: Mega pixel OCR vision sensor MVS-OCR2 Series

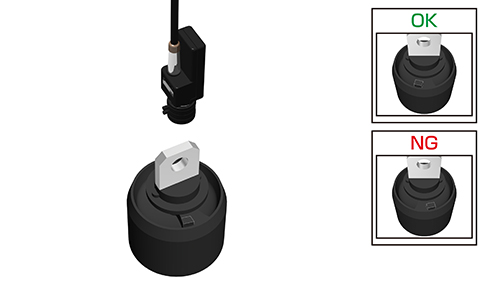

Checking side of the cap at feeding process

Checking side of the cap at feeding process by CVS2 series.

It can detect color and shape so it can detect wrong cap and side of the cap. Its masking function will help efficient inspection.

Model: Pattern matching & Color are sensor CVS2-N21-RA

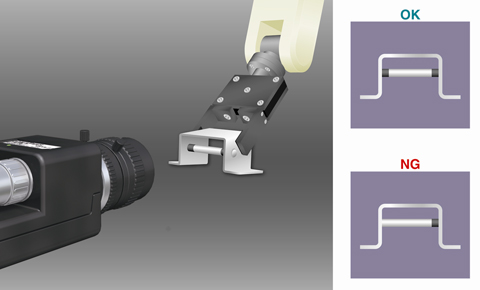

Checking shape of assembled parts

Checking shape of the assembled parts by CVS3 series.

It can detect contour by edge detecting function utilizing backlight.

Model: Edge sensor CVS3-N21-RA

Checking if the springs are correct or not

Checking if the springs are correct or not by MVS-PM-R.

When the number of turning of the spring is different, color area detected by MVS-PM-R will be different in the inspection window. Then, it can reject wrong spring by the result.

Model: Color pattern matching camera MVS-PM-R Series

Checking existence of LOCTITE

Checking existence of LOCTITE supplied on the bolt by MVS-PM-R.

It can check color area in the inspection window and reject ones with less LOCTITE.

Model: Color pattern matching camera MVS-PM-R Series

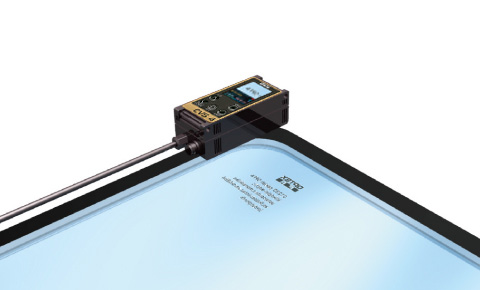

Print inspection on the sun-roof glass plate

Print inspection on the sun-roof glass plate by CVS4 series.

It can check if the glass plate is correct one or not by print inspection.

Model: OCR sensor CVS4-N21W-R

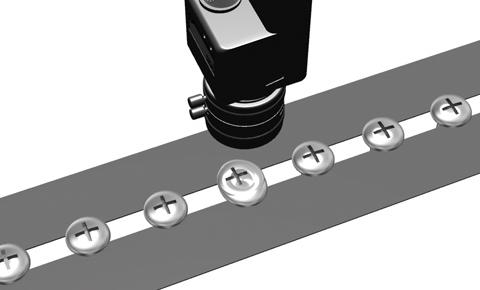

Checking shape of the screw head

Checking shape of the screw head by MVS-PM-R.

By checking contour of screw head, it can reject wrong or broken screw.

Model: Color pattern matching camera MVS-PM-R Series

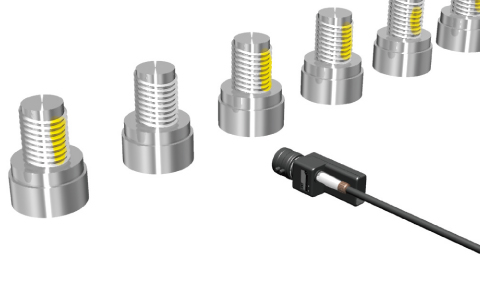

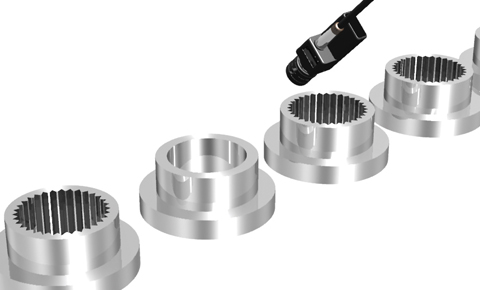

Checking existence of grooves at inside of the parts

Checking existence of grooves at inside of the parts by MVS-PM-R.

The reflection changes if there is no grooves inside of the parts. MVS-PM-R can detect the difference of reflection from the inside of the parts.

Model: Color pattern matching camera MVS-PM-R Series

Checking number of grooves on the piston

Checking number of grooves on the piston by MVS-EM-R.

It can count number of grooves on the piston by "edge count" correctly. Just counting number means it doesn't need size calibration so it will be very easy inspection.

Model: Measurement camera MVS-EM-R Series

Detecting wrong type axel pedal fed mixed in the process

Detecting wrong type axel pedal fed mixed in the process by checking the marking on the pedal by CVS4 series.

When it is difficult detecting wrong type pedal by checking shape, you can utilize character recognition on the marking on the pedal.

Model: All in one OCR vision sensor CVS4-R Series

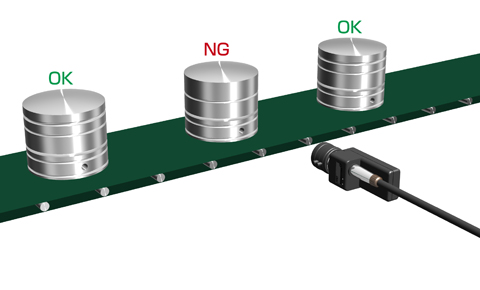

Checking side of round metal parts

Checking side of round metal parts by CVS3-RA series.

Utilize its function "contour", it can detect which side the parts are sitting on the conveyer.

Model: All in one edge sensor CVS3-RA Series

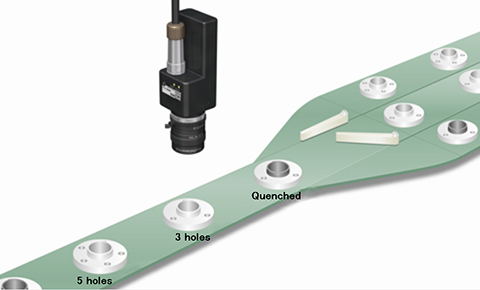

Detecting quenched or not and types by number of holes

Detecting if the gears are quenched or not and also type by number of holes by MVS-PM-R.

It can sort up to 16 types by colors or shapes of target objects. It will help efficiency and accuracy of sorting.

Model: Color pattern matching camera MVS-PM-R Series

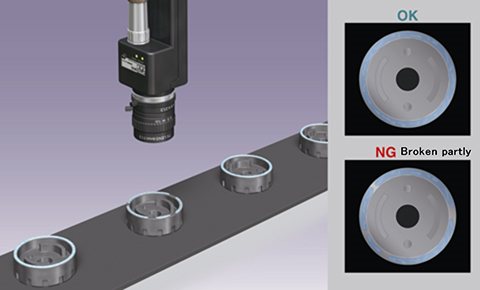

Checking existence of balls on the ball bearing

Checking existence of balls on the ball bearing by MVS-PM-R.

It can have up to 16 inspection windows so you can check existence of each ball on the ball bearing at one time.

Model: Color pattern matching camera MVS-PM-R Series

Checking glue amount on the metal surface

Checking glue amount on the metal surface by MVS-PM-R.

Detect broken part of glue supplied on the metal surface and reject it. Masking function will help better accuracy of inspection of MVS-PM-R.

Model: Color pattern matching camera MVS-PM-R Series

Checking wrong parts fed mixed

Checking wrong parts fed mixed by MVS-PM-R.

"contour" function will work fine for this application. It can detect the shape clearly and reject wrong parts efficiently.

Model: Color pattern matching camera MVS-PM-R Series

Checking marking on the meter panel parts

Checking marking on the meter panel parts by MVS-PM-R.

Choose LED lighting and align correctly so that the marking shows clearly. Normally, coaxial lighting will work fine in this case.

Model: Color pattern matching camera MVS-PM-R Series

Checking if the hinge parts are assembled correctly or not

Checking if the hinge parts are assembled correctly or not by MVS-PM-R.

Setting 2 inspection windows at left and right side of the frame and pin so that it can detect if the pin is set correctly or not.

Model: Color pattern matching camera MVS-PM-R Series

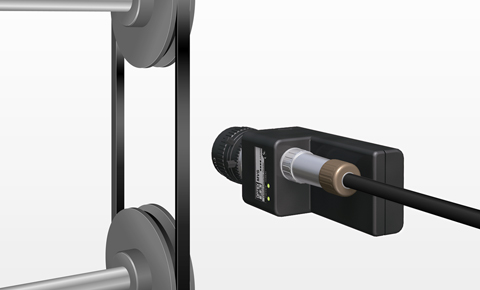

Measurement of fan belt width

Measurement of fan belt width by MVS-EM-R.

By "outer dimension" function, it can measure the width of the fan belt accurately. You can measure maximum part, minimum part and average in the inspection window.

Model: Measurement camera MVS-EM-R Series

Checking marking on the pipe

Checking marking on the pipe by MVS-PM-R.

By "color and shape" function, it can check not only its color but also shape of the marking at one time. It has 32 bank setup memory so you can change the setup by switching the bank for 32 different workpieces easily.

Model: Color pattern matching camera MVS-PM-R Series

Sorting mounting bush by color of marking

Sorting mounting bush by color of marking by CVS2-RA series.

It can output sorting result up to 3 types. When RS-232C is used, up to 15 types can be sorted.

Model: All in one pattern matching & Color area sensor CVS2-RA Series

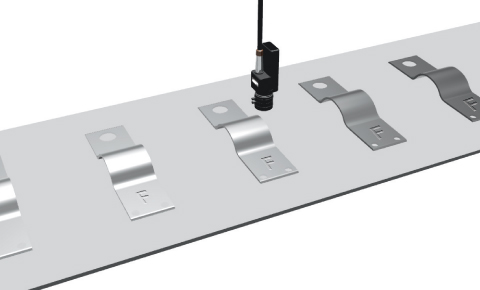

Detecting wrong type metal plate fed mixed in the process

Detecting wrong type metal plate fed mixed in the process by checking the contour of the plate by CVS3 series.

By checking contour of the whole part of the plate, it can detect not only the shape of the plate but also holes on the plate.

Model: All in one edge sensor CVS3-RA Series

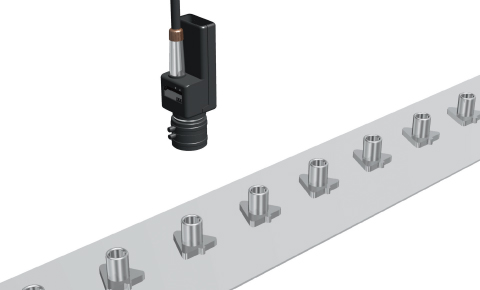

Checking position of the bushing

Checking position of the bushing by CVS3-RA series.

Because it's all in one vision sensor, you don't have to install lighting, camera, monitor and controller separately so installation will be very simple.

It can detect shape and also deviation of bushing position by edge detection.

Model: All in one edge sensor CVS3-RA Series

Detecting wrong type parts fed mixed in the process

Detecting wrong type parts fed mixed in the process by checking whole part of the parts by MVS-PM-R series.

By "full color" function, checking color of whole part of the parts, it can detect type of the parts for example, for left steering type or for right steering type.

Model: Color pattern matching camera MVS-PM-R Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Others