Vision Sensors

Detecting direction/sides

- Ice Cream Container Lid Orientation Detection

- Dry Cell Electrode Inspection

- Detecting direction of the carton box

- Checking side of the metal disk

- Checking hole position on the rubber parts

- Checking direction of parts for automotive

- Checking side of the cap at feeding process

- Checking side of round metal parts

- Checking side of the parts on the feeder

- Checking direction and side of the parts in carrier tape

- Checking direction of the individual package by checking printed characters

- Checking side and direction of the box

- Checking side of package of instant noodle

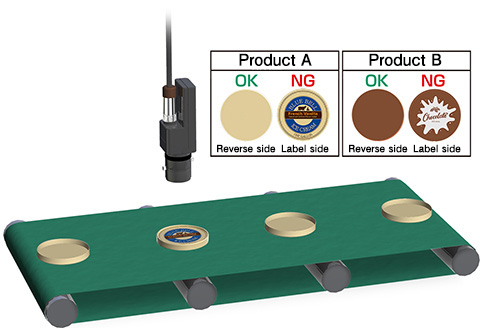

Ice Cream Container Lid Orientation Detection

With the MVS-PM-R color pattern matching vision sensor, the contamination matching mode allows for inspection of the lid orientation of cup-type ice cream containers.

By setting the reverse side as OK and the label side as NG, the MVS-PM-R is able to inspect for package illustrations on the surface for accurate detection of the lid orientation. The contamination matching mode also checks for patterns rather than just differences in color.

This means inspection can be performed without the need to reconfigure camera settings even if the product type changes.

Model: Color pattern matching camera MVS-PM-R Series

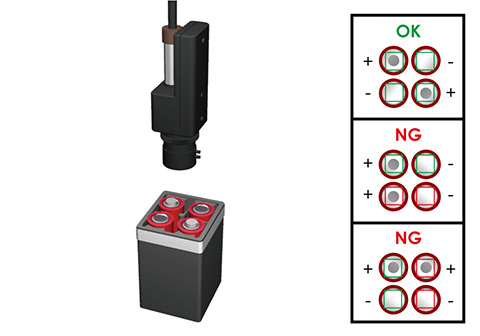

Dry Cell Electrode Inspection

The contamination matching mode of the MVS-PM-R color pattern matching vision sensor facilitates inspection of battery insertion directions.

Inspection windows can be set to display each of the positive and negative poles of four batteries.

Positive poles cast a shadow on the image from the shape of the pole’s protrusion, so setting a threshold for the area ratio of the black part of the shadow makes it possible to determine whether the batteries are inserted correctly in each inspection window.

Model: Color pattern matching camera MVS-PM-R Series

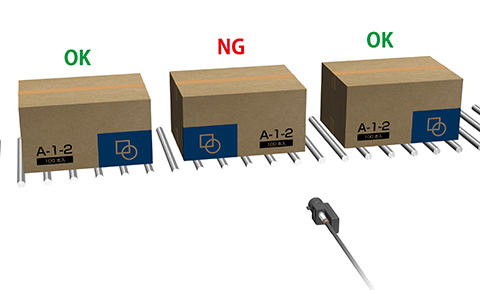

Detecting direction of the carton box

Detecting direction of the carton box by MVS-PM-R.

The box sitting at wrong direction may have to be relocated by robot. MVS-PM-R can provide direction information utilizing multiple inspection windows available up to 16 for robot control system.

Even if the image captured by the camera is not so clear, it can detect the direction by "full color" function.

Model: Color pattern matching camera MVS-PM-R Series

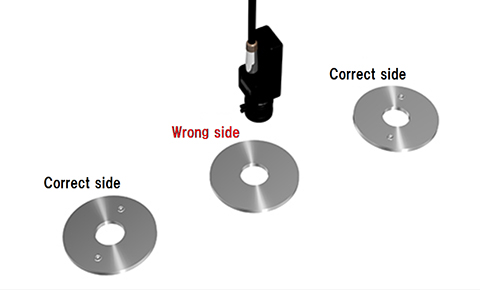

Checking side of the metal disk

Checking side of the metal disk by MVS-PM-R.

It can detect small difference like small marks on the up side and can reject wrong side has no mark.

"stain" function will work fine even if the contrast is low.

Model: Color pattern matching camera MVS-PM-R Series

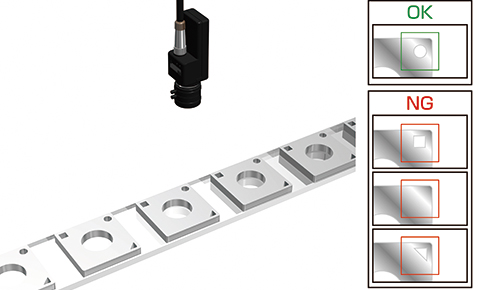

Checking hole position on the rubber parts

Checking hole position on the rubber parts by MVS-PM-R.

General purpose photoelectric sensor can't detect the hole if the positioning of the rubber parts is not done correctly though, MVS-PM-R series can detect the hole if the hole is in its FOV. It also can have up to 16 inspection window so you can detect which area the hole position is deviated.

Model: Color pattern matching camera MVS-PM-R Series

Checking direction of parts for automotive

Checking direction of parts for automotive by MVS-PM-R.

By checking multiple parts of the target object utilizing multiple inspection window that MVS-PM-R can have up to 16, it can detect direction of the parts.

Model: Color pattern matching camera MVS-PM-R Series

Checking side of the cap at feeding process

Checking side of the cap at feeding process by CVS2 series.

It can detect color and shape so it can detect wrong cap and side of the cap. Its masking function will help efficient inspection.

Model: Pattern matching & Color are sensor CVS2-N21-RA

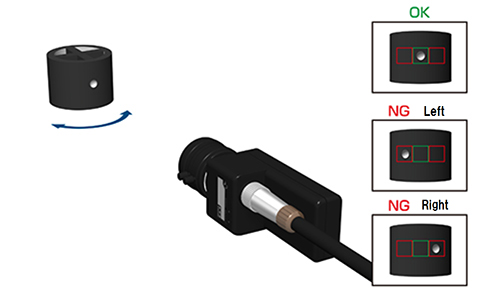

Checking side of round metal parts

Checking side of round metal parts by CVS3-RA series.

Utilize its function "contour", it can detect which side the parts are sitting on the conveyer.

Model: All in one edge sensor CVS3-RA Series

Checking side of the parts on the feeder

Checking side of the parts on the feeder by MVS-PM-R.

It can detect side of the parts by checking shape or color of the parts.

Model: Color pattern matching camera MVS-PM-R Series

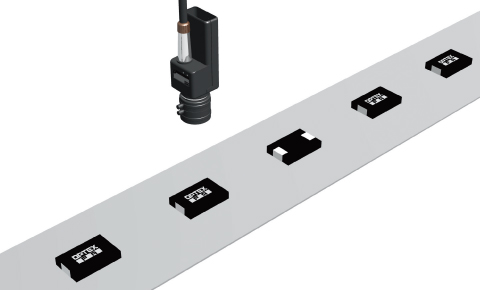

Checking direction and side of the parts in carrier tape

Checking direction and side of the parts in carrier tape by CVS3.

It can compare the parts image with master image and detect wrong direction or wrong side of the parts.

Model: Edge sensor CVS3-N21-RA

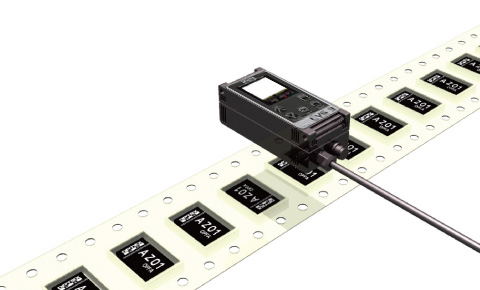

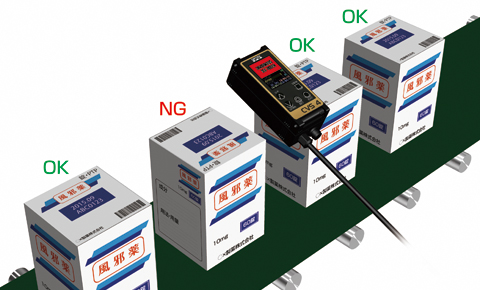

Checking direction of the individual package by checking printed characters

CVS4-R can check if the date code is correct and also it can count character number of lot number. By checking printed characters, it can check if the direction of the box is correct or not.

Model: Character recognition vision sensor CVS4-R Series

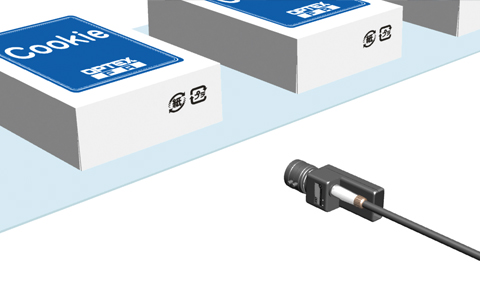

Checking side and direction of the box

Checking side and direction by checking position of printed mark on the box. MVS-PM-R can detect shape and color so it can check if the mark is correct or not.

Model: Color pattern matching camera MVS-PM-R Series

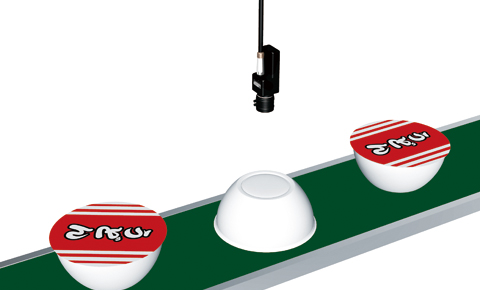

Checking side of package of instant noodle

Checking if the package is sitting on the conveyer correctly or not by MVS-PM-R.

Using "color area" function, it can detect correct side of the package. It can prevent outflow of upside down package to next process.

Model: Color pattern matching camera MVS-PM-R Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Other