Vision Sensors

Composite inspection

- Mixed Juice Box Varieties and Positioning

- Presence of label on back side and print inspection of expiration date

- Complex inspections of packages and marking

- Checking existence of sealing tape and certificate label

- Three cameras inspection independently

- Checking shelf life and wrong box

- Print inspection on rice cake package and checking existence of antioxidant in the package

- Print inspection on two surface of the can

- Print inspection on packages of source on 3 lines

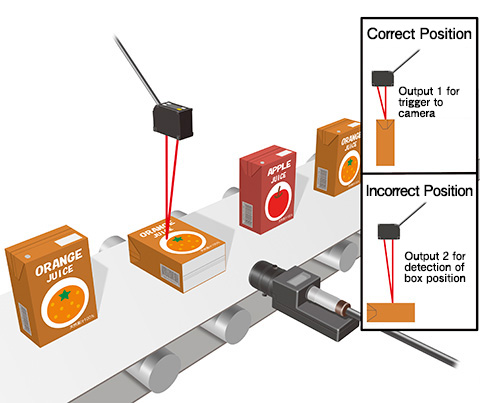

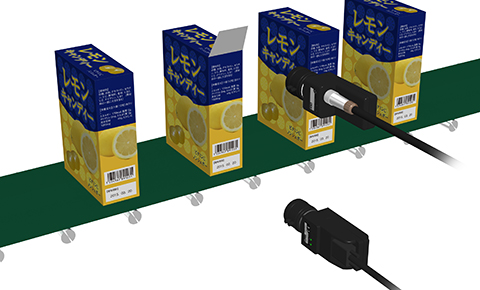

Mixed Juice Box Varieties and Positioning

The color-area mode of the MVS-PM-R pattern matching vision sensor makes it possible to detect differences in package color, preventing different varieties of packaged beverage products from being conveyed.

In addition, the BGS-HDL C-MOS laser sensor with two control outputs can be selected for the vision sensor’s trigger sensor.

The output 1 can be set for a trigger signal to the vision sensor for inspection of mixed product varieties, when a juice box passes at the correct height, leaving output 2 available to detect incorrect orientation when a juice box has fallen over on its side. In this way, both camera triggering and sideways package detection can be performed using a single sensor.

Model: Color pattern matching camera MVS-PM-R Series

Model: High-resolution C-MOS Laser Sensor BGS-HDL Series

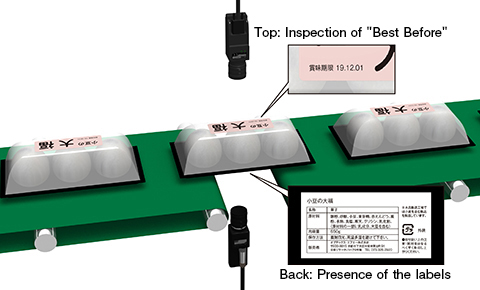

Presence of label on back side and print inspection of expiration date

MVS-PM-R of the pattern matching camera checks the presence of the back side label, and inspects the expiration date on the label with the OCR camera MVS-OCR2.

The controller MVS-DN-E can connect up to three cameras.

Since only one controller is required, it is possible to construct an inspection system with low cost.

Model: Color Pattern Matching Camera Unit MVS-PM-R Series

Model: Color OCR Camera Unit MVS-OCR2 Series

Complex inspections of packages and marking

The MVS-OCR2 character recognition camera enables inspection of printed expiration dates, and the MVS-PM-R pattern matching camera enables inspections of contents and packaging errors.

Connecting these two cameras using the MVS-DN-E controller makes it possible to configure an AND circuit within the controller. This allows for inspections of poorly printed text and packaging errors without the need to organize sequences using a PLC.

Model: Color Pattern Matching Camera Unit MVS-PM-R Series

Model: Color OCR Camera Unit MVS-OCR2 Series

Checking existence of sealing tape and certificate label

MVS-PM-R will be able to detect existence of the sealing tape and the certificate label easily without affection from color pattern of the box by teaching without those tapes.

Model: Color pattern matching camera MVS-PM-R Series

Three cameras inspection independently

Up to 3 cameras can be connected to one controller MVS-DN(DP) and inspection can be done independently.

For example, one camera checks existence of the straw on the side, another camera checks direction of the package and last camera checks date and lot number from top. You don't have to have 3 controllers for 3 cameras.

Model: Multi camera vision sensor MVS Series

Checking shelf life and wrong box

Checking shelf life and wrongly made box by print inspection camera MVS-OCR2 and pattern matching camera MVS-PM-R.

Up to 3 cameras can be connected and controlled by one controller that reduces total cost of investment and make system configuration simple.

Model: Color pattern matching vision sensor MVS-PM-R Series

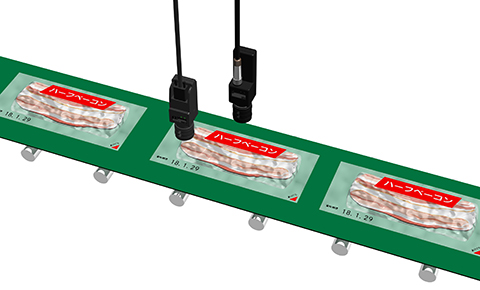

Print inspection on rice cake package and checking existence of antioxidant in the package

Print inspection of shelf life by MVS-OCR2 and checking existence of antioxidant in the package by MVS-PM-R.

The controller MVS-DN can control up to 3 cameras so you don't have to have multiple controller in this case.

Either wrong printing nor missing antioxidant will be rejected by single output from the controller.

Model: Mega pixel character recognition camera MVS-OCR2 Series

Print inspection on two surface of the can

Print inspection on the shelf life printed on top and print inspection on the label attached on the side of the can at one time by two MVS-OCR2.

The controller MVS-DN can control up to 3 cameras so you don't have to have multiple controller in this case.

Wrong printing on the shelf life or on the label at side of the can will be rejected by single output from the controller.

Model: Mega pixel character recognition camera MVS-OCR2 Series

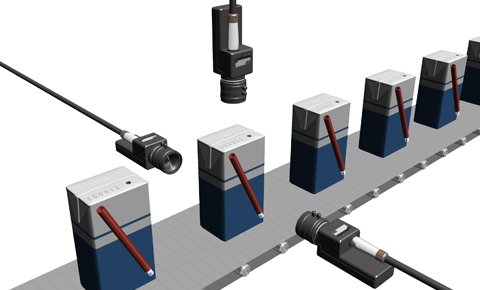

Print inspection on packages of source on 3 lines

Print inspection on the shelf life on 3 production lines can be done by 3 MVS-OCR2.

The controller MVS-DN can control up to 3 cameras so you don't have to have multiple controller and reduce cost in this case.

Model: Mega pixel character recognition camera MVS-OCR2 Series

Application examples

by industry

- Foods

- Beverage

- Chemical/Cosmetics

- Packaging

- Semicon

- FPD/PV

- Electric

- Electronics Components

- Automotive

- Machinery

- Rubber/Plastic

- Metal

- Steel

- Logistics

- Other