Non-Contact Thermometers

Rubber/Plastic

- Temperature Measurement of Raw Plastic Sheets

- Temperature Management for Sheet Material Bonding Processes

- Temperature Management for Rubber Kneading Processes

- Temperature Measurement in Rubber Extrusion Processes

- Heating Time Control in Tire Vulcanization Processes

- CTemperature Management of Molded Plastic Products

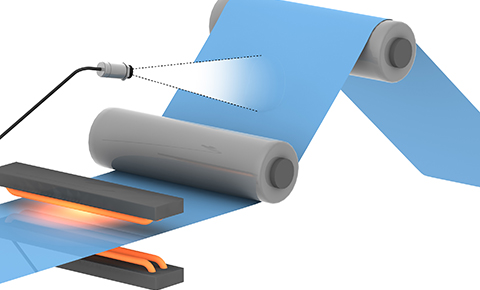

Temperature Measurement of Raw Plastic Sheets

In the manufacturing process for raw plastic sheets, variations in the heating temperature can cause wrinkles to occur.

Measuring the sheet temperature using a CS series non-contact thermometer makes it possible to control the heater to ensure a consistent temperature.

This ability to ensure a fixed heating temperature allows for a constant manufacturing quality.

Model: Installation in Limited Space Type CS Series

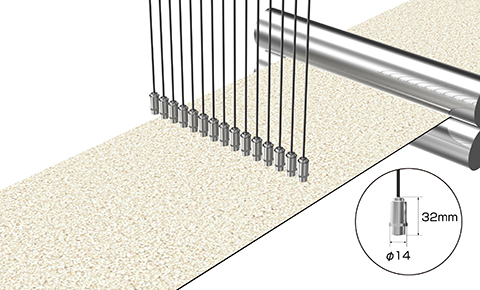

Temperature Management for Sheet Material Bonding Processes

The CS non-contact thermometer can be used to manage the temperature of the heating roller to ensure the roller is heated to the correct temperature for bonding sheet material.

With a diameter of just ø14 mm, the compact size of the CS sensor head makes it possible to use multiple units for multi-point measurement without taking up too much space.

In addition, with a heat resistance of up to 120°C, the GT-Slim is designed to provide high environmental resistance even when placed close to high-temperature workpieces.

Model: Installation in Limited Space Type CS Series

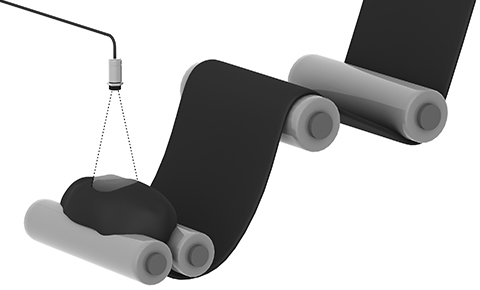

Temperature Management for Rubber Kneading Processes

In the rubber kneading process, rubber materials are thoroughly mixed and molded into a plate shape.

In order to prevent excessive increases in temperature in the kneading process to keep the material from burning, monitoring the temperature is a must.

Because the CS series is a non-contact thermometer, temperatures can be measured even during kneading.

This allows for constant temperature monitoring.

Model: Installation in Limited Space Type CS Series

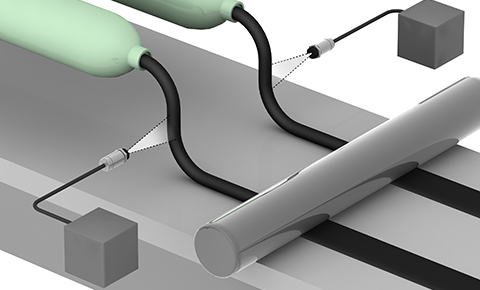

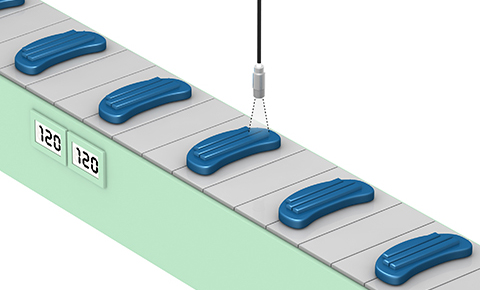

Temperature Measurement in Rubber Extrusion Processes

The CS non-contact thermometer can be used to measure the temperature of tire rubber coming out of the extruder.

Because heating temperatures with conventional systems are adjusted using only the temperature controller, variations in quality due to seasonal factors occurred.

Monitoring the temperature with the CS and incorporating the analog output into a PLC makes it possible to adjust the extrusion speed in order to ensure quality is kept at a constant.

Model: Installation in Limited Space Type CS Series

Heating Time Control in Tire Vulcanization Processes

During the heating and shaping process for tires, variations in quality can be caused by seasonal factors such as temperature variations between winter and summer.

With the CS non-contact thermometer, vulcanization time adjustments are possible by measuring the tire temperature before being placed on the vulcanizer.

Such temperature management helps ensure constant quality.

Model: Installation in Limited Space Type CS Series

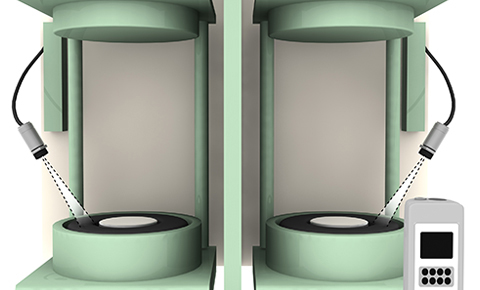

Temperature Management of Molded Plastic Products

The CS non-contact thermometer can be used for measuring temperatures to ensure resin products are molded at the correct temperature.

Whereas conventional systems involved adjustment using only a temperature controller, resulting in variations in quality, measuring the molding temperature using a non-contact thermometer with feedback control makes it possible to ensure constant quality during the molding process. This leads to improved quality and improved yield.

Model: Installation in Limited Space Type CS Series