IO-Link Basic Knowledge

This section provides an easy-to-understand overview of IO-Link, its features and benefits.

What is IO-Link?

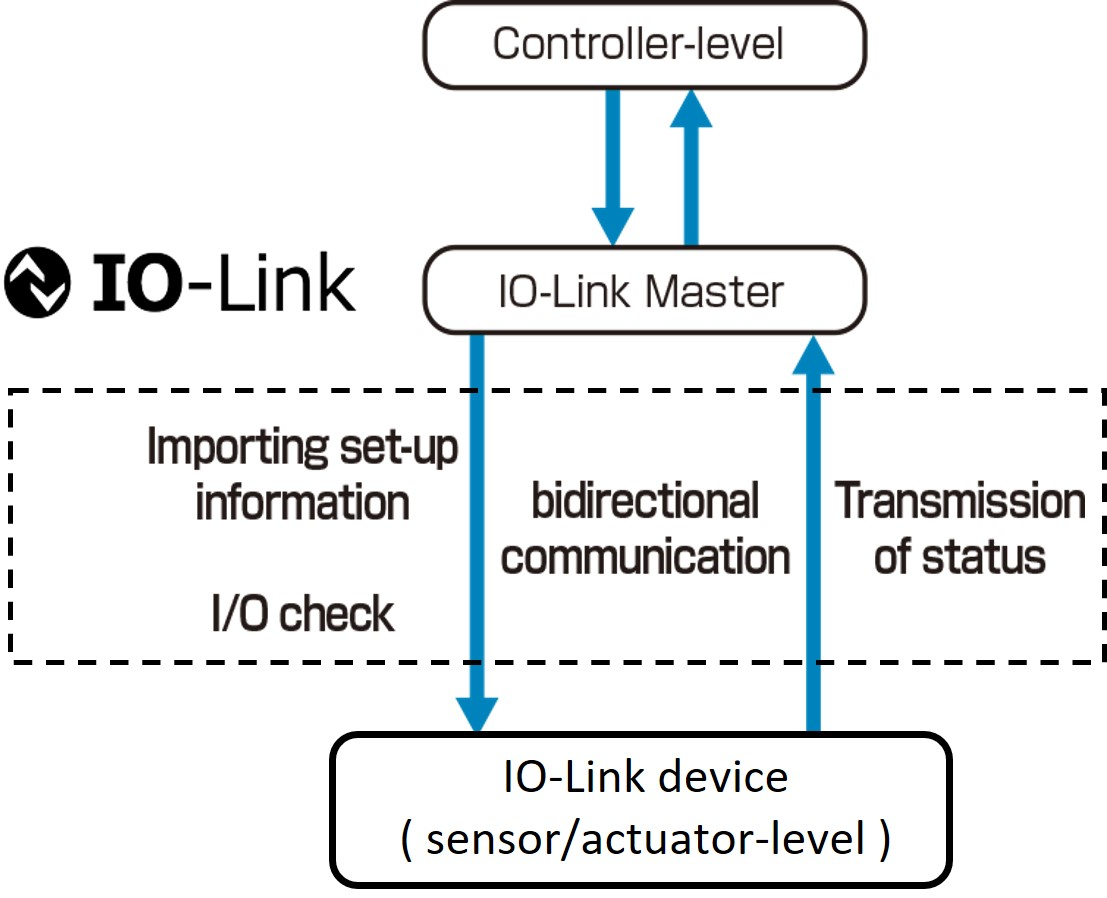

O-Link is an industrial interface standard (IEC 61131-9) that connects sensors and actuators. This communication technology enables the exchange of various types of data, which have been managed manually one by one, at the sensor level in line with IIoT.

IO-Link compatible sensors and actuators are called IO-Link devices, which are connected to various industrial networks such as EtherNet/IP, EtherCAT, PROFINET, Modbus TCP, CC-Link IE TSN, CC-Link IE Field and CC-Link IE Field Basic through the IO-Link Master.

Sensors and actuators are connected to the IO-Link Master point-to-point, and are connected to controllers such as PLCs via industrial Ethernet.

POINT

Accelerate IIoT by accessing various data from sensors and actuators.

This technology enables IoT in factories, starting with IO-Link devices at the sensor-level in line.

IO-Link Features

Data Acquisition

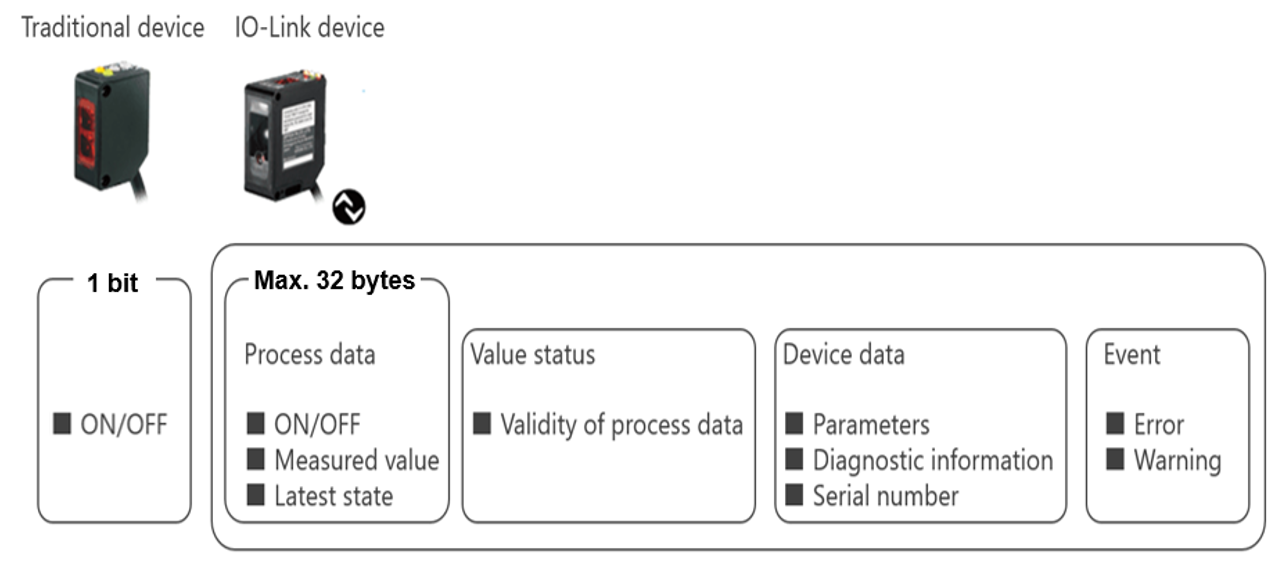

In recent years, there has been an increasing need to digitize data from analog devices and incorporate it into systems. For this purpose, conventional devices are replaced with IO-Link devices. This is expected to reduce the number of devices such as A/D converters or lower the cost of devices.

Conventionally, at the sensor and actuator-level, ON/OFF signals, analog signals, and serial communications were wired separately. The IO-Link standardizes these processes, enabling more efficient operation.

At the same time, the following issues related to the use of analog I/O signals can also be solved.

- Change in measured values due to noise

- Convert errors during A/D or D/A conversion

- Scaling man-hours

POINT

This enables visualization of data that could not be obtained before and detection of system abnormalities and failures.

Making machine and plant maintenance more efficient

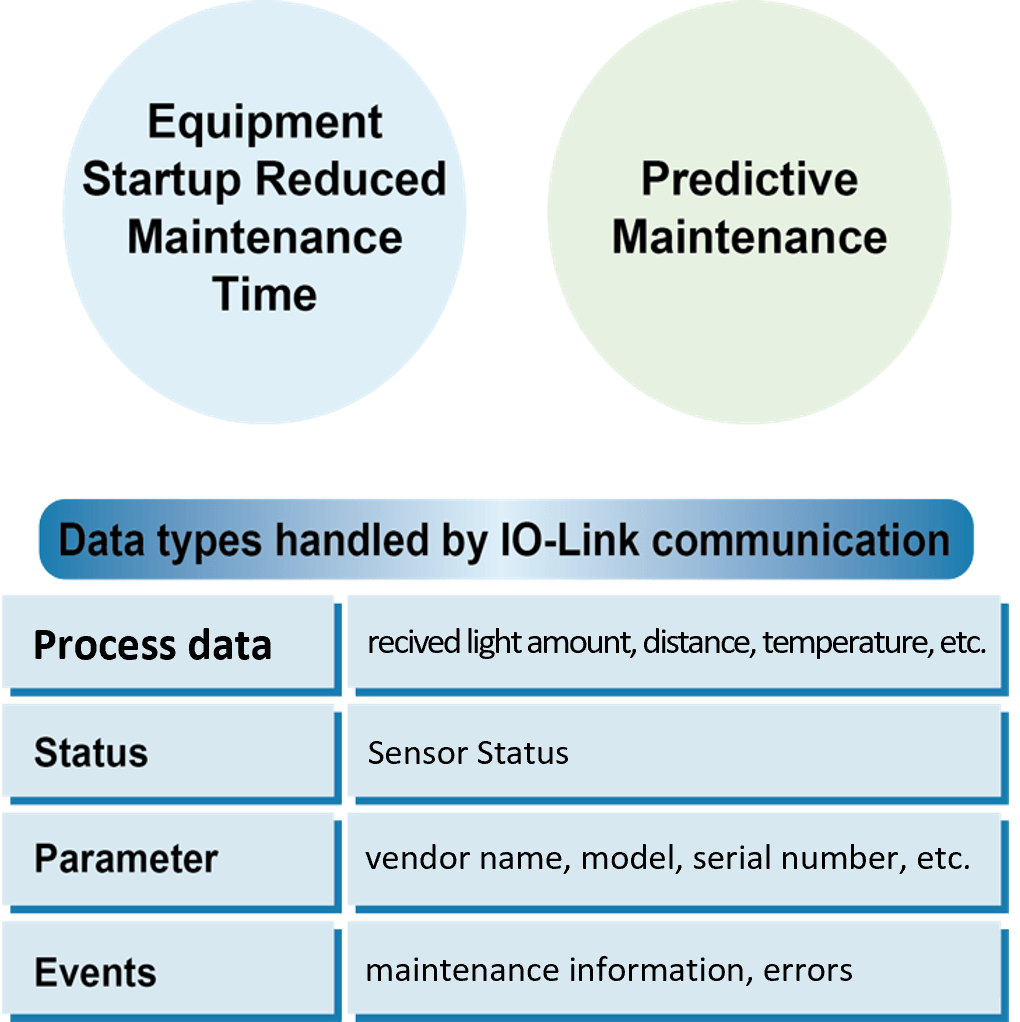

Since the parameters once set can be backed up to the IO-Link Master, it is possible to avoid problems such as wrong model if the IO-Link device is replaced with one of the same model.

In addition, set-up information can be imported from IO-Link Master when replacing IO-Link devices, eliminating the need to fine-tuning.

The IO-Link Master can back up not only the profile of each IO-Link device, but also the setting information after various parameter adjustments.

If the IO-Link device is replaced with one of the same model, the setting information can be restored to avoid different information than before.

What you can do with IO-Link

-

IO-Link reduces equipment start-up and maintenance time.

This means that batch sensor settings and I/O checks can be performed from PLC. In addition, an automatic restore function allows the same settings as those of the sensor before replacement to be imported from the IO-Link Master, so maintenance can be completed simply by wiring.

IO-Link Complete Guide

Back to top