LED Lighting

Printing inspection

- Print inspection on transparent bottle

- Print inspection over crease of film packaging

- Print inspection of colored characters on white plastic bottle

- Checking cavity number on the connector for automotive

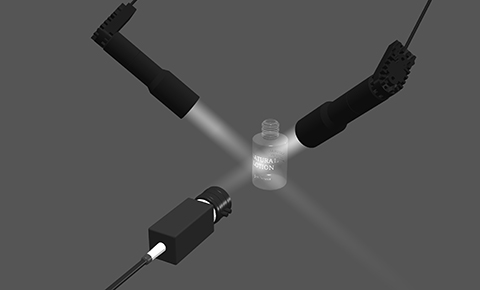

Print inspection on transparent bottle

Inspecting white characters printed on the transparent bottle utilizing spot lighting OPS-S series and machine vision.

By lighting at small area by two spot lighting with condensing lens, the characters can be detected without affection by printed characters at opposite side of the bottle.

Model: Sensing spot lighting OPS-S20W

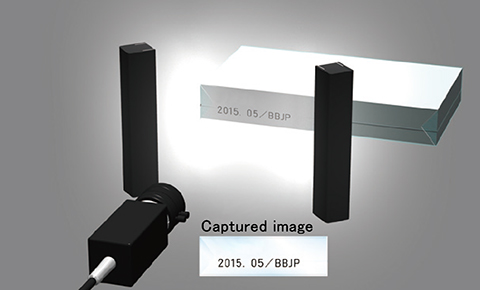

Print inspection over crease of film packaging

When printing is done over crease of film packaging, OCR vision sensor would not be able to recognize characters because of the line which is made by the crease.

By installing two bar lightings, the line will be cancelled and OCR vision sensor will be able to recognize characters correctly.

Model: High brightness bar lighting OPB-10015W2

Print inspection of colored characters on white plastic bottle

When inspecting yellow colored characters printed on white bottle, by utilizing two blue bar lighting, the camera can capture the characters as black colored characters which is because of blue lighting as complementary color of yellow.

If the color of the character is red or white, you have to change color of lighting accordingly. Also backlight would not work correctly may shows printed mater at back side.

Model: High brightness bar lighting OPB-20015B

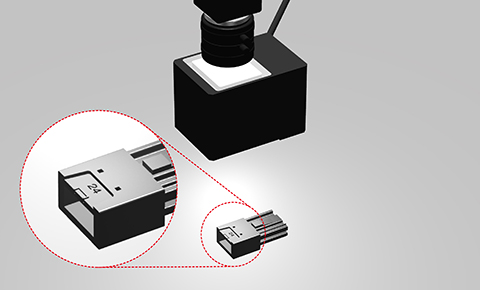

Checking cavity number on the connector for automotive

Detecting the cavity number of the connector utilizing coaxial lighting.

Thanks to OPX's highly uniform illumination with a narrow directivity angle light, small cavity number can be detected clearly. Because the illumination is highly uniform, the installing position of the lighting can be flexible even at the short range area.

Model: Sensing coaxial lighting OPX Series