No.2

Fiber-Optic Sensors application example

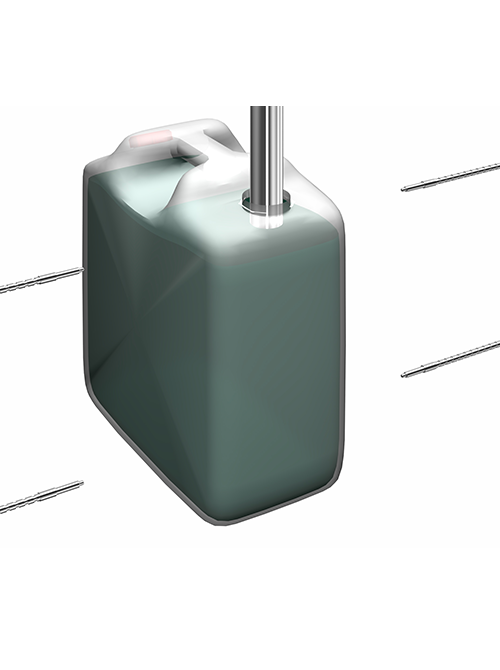

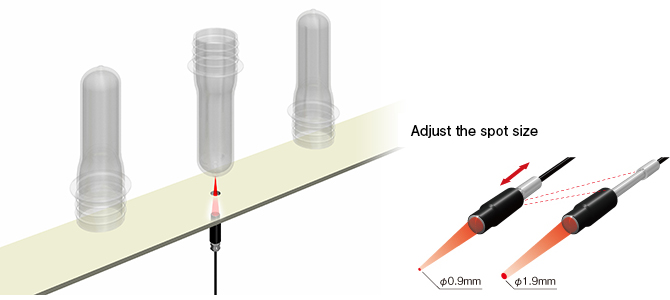

Detecting upside-down preform tube

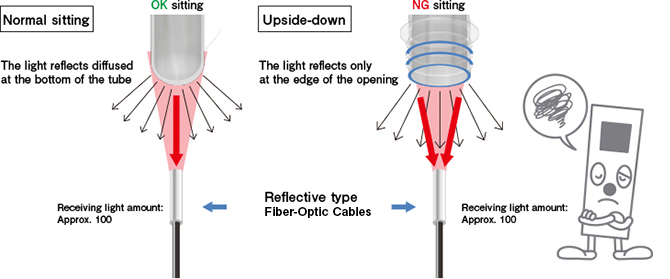

Problem: Small difference of receiving light

Up and bottom side of the preform tube must be defined before bottle molding. Although, tried to define it by Fiber-Optic Sensors, it couldn't distinguish top or bottom because the difference of the reflection from the top side and bottom side is too small.

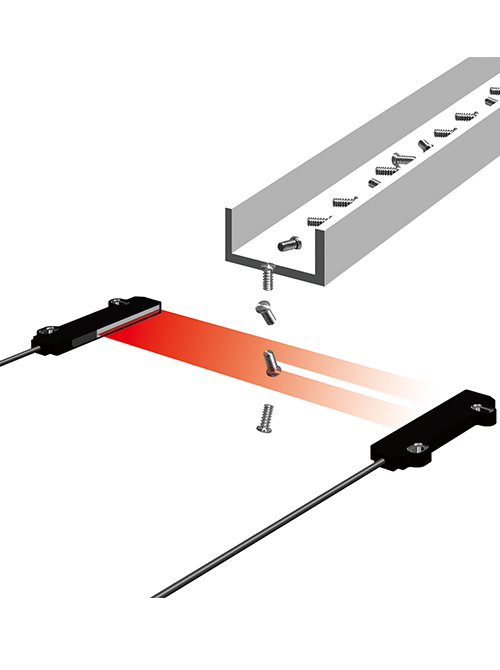

Solution: Emit as pin-spot light utilizing spot size adjustable lens

Upside-down of preform tube can be detected by spot size adjustable lens NF-DA06 and Fiber-Optic Sensors NF-DM02-G4.

The diameter of the spot size can be adjustable from φ0.9mm up to φ1.9mm so it can be set as requested.

It can distinguish top side or bottom side of the preform tube by small spot size which make big enough difference of the reflection from those parts to define if it's top side or bottom side.