No.4

Fiber-Optic Sensors application examples

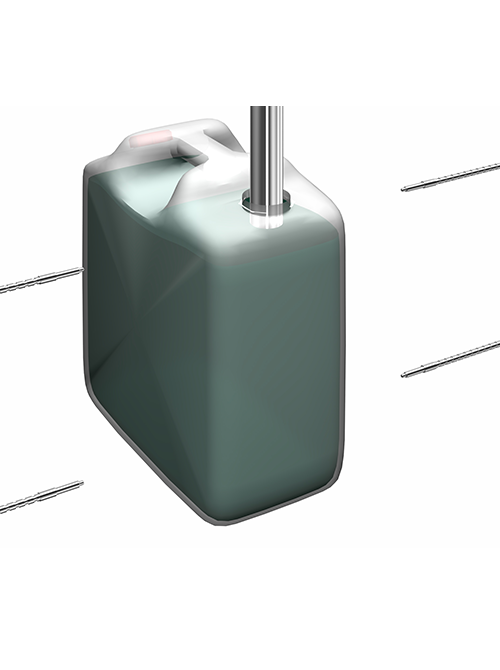

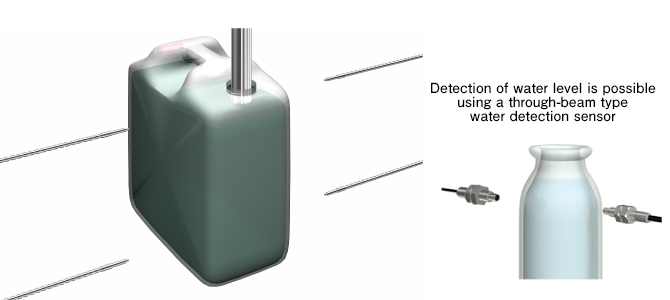

Level detection of liquids in semi-transparent containers

Problem: Detection of liquid levels not always possible

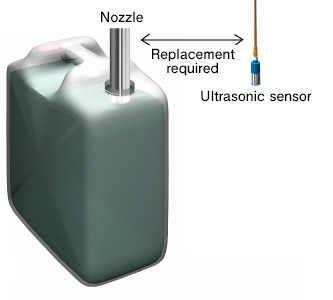

Using ultrasonic sensors to detect liquid levels in semi-transparent containers requires replacing the nozzle and the ultrasonic sensor.

The inability to detect liquid levels when injecting or discharging liquid using a nozzle makes for a very inconvenient setup.

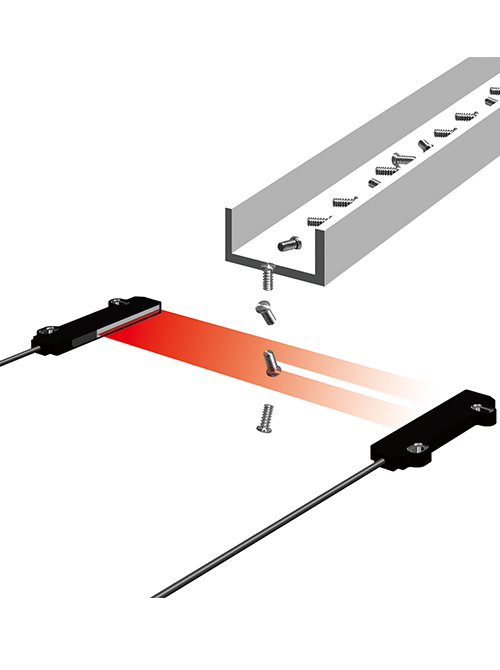

Solution: External detection using a water detection Fiber-Optic Sensors and Fiber-Optic Cables

With the D3IF series water detection Fiber-Optic Sensors and the NF-TW01 Fiber-Optic Sensors, liquid levels can be detected from outside the semi-transparent container.

The D3IF-TN water detection Fiber-Optic Sensors uses an infrared LED with a wavelength absorbed by water (1.45 μm) for the light source.

When used with the NF-TW01 water detection unit (through-beam type), this Fiber-Optic Sensors enables detection of liquid levels from outside a semi-transparent container.

With two Fiber-Optic Sensors, detection of full (injecting stop), a specified fill amount, and an absence of liquid (injection start) are possible.

Detection from outside the semi-transparent container means replacing the nozzle is unnecessary, allowing for liquid levels to be detected even when injecting or discharging liquid.