03 How to Measure Workpiece Temperature Through a Furnace Window

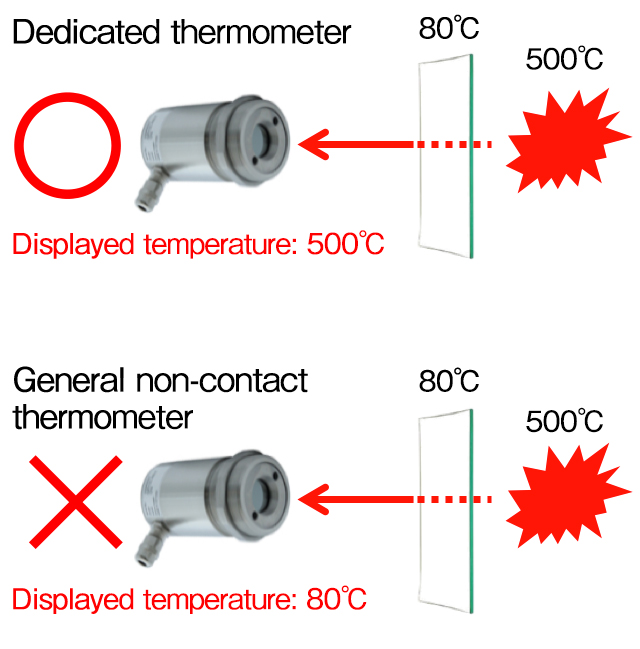

Measuring the temperature of a workpiece through a furnace window using a general non-contact thermometer (with a detection wavelength of 8 to 14 μm) is almost impossible. As such, temperatures inside the furnace are often measured using a thermocouple (contact type), which cannot clearly determine if the workpiece has reached the set temperature.

By using a dedicated non-contact thermometer, however, users are able to overcome this difficulty and accurately measure workpiece temperatures through a furnace window. This section provides a selection guide for determining the appropriate model in just three easy steps.

By using a dedicated non-contact thermometer, however, users are able to overcome this difficulty and accurately measure workpiece temperatures through a furnace window. This section provides a selection guide for determining the appropriate model in just three easy steps.

Step 1: Check the conditions.

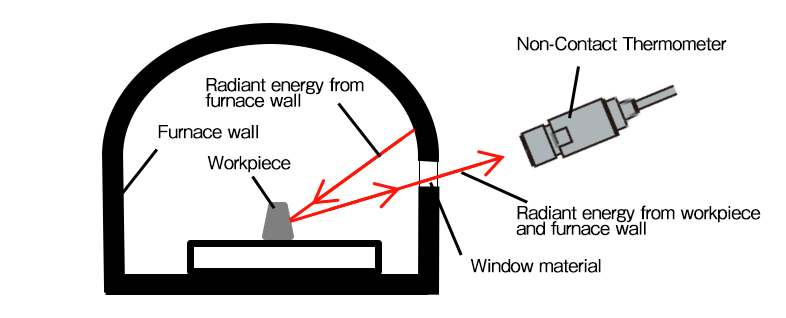

To measure a workpiece through a furnace window, the furnace wall temperature must be constant.

The reason for this is because radiant energy from the furnace wall is reflected onto the surface of the workpiece, and fluctuations in the furnace wall temperature can cause adverse effects on the workpiece temperature.

Ensuring the furnace wall temperature is constant will ensure repeatability and stable measurements.

The reason for this is because radiant energy from the furnace wall is reflected onto the surface of the workpiece, and fluctuations in the furnace wall temperature can cause adverse effects on the workpiece temperature.

Ensuring the furnace wall temperature is constant will ensure repeatability and stable measurements.

Step 2: Check the window material.

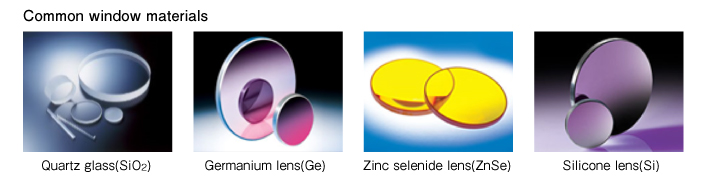

To measure temperatures through the window, it is necessary to know what window material is being used.

Knowing the window material being used makes it possible to ensure the infrared rays in the measurement wavelength region of the non-contact thermometer can sufficiently penetrate through the window.

Measurements performed using a thermometer with a wavelength region that is not transmitted through the window material will make it impossible to measure the workpiece and instead measure the window material itself.

Knowing the window material being used makes it possible to ensure the infrared rays in the measurement wavelength region of the non-contact thermometer can sufficiently penetrate through the window.

Measurements performed using a thermometer with a wavelength region that is not transmitted through the window material will make it impossible to measure the workpiece and instead measure the window material itself.

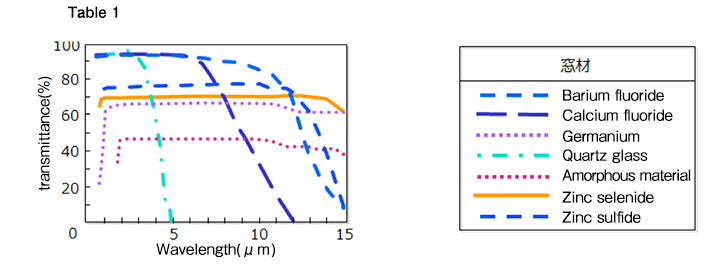

Table 1 shows the transmittance of commonly used window materials. Note how the transmittance varies depending on the material.

For quartz glass, for example, infrared rays are transmitted at 3 μm or less.

Therefore, infrared rays with wavelengths of 3 μm or more will not penetrate quartz glass.

For quartz glass, for example, infrared rays are transmitted at 3 μm or less.

Therefore, infrared rays with wavelengths of 3 μm or more will not penetrate quartz glass.

Barium fluoride and calcium fluoride transmit infrared rays of 6 μm or less, but other window materials allow for no more than 80% transmittance regardless of wavelength.

To ensure measurement of workpiece temperatures is possible through the window, window material with a high transmittance should be used.

For more information on window materials, visit the Sigma Koki website below:http://www.sigma-koki.com/index.php?lang=en

To ensure measurement of workpiece temperatures is possible through the window, window material with a high transmittance should be used.

For more information on window materials, visit the Sigma Koki website below:http://www.sigma-koki.com/index.php?lang=en

Step 3: Select the appropriate model.

In the previous example, it was determined that a non-contact thermometer with a detection wavelength of 3 μm or less should be used for quartz glass windows.

OPTEX FA offers the BF series of special application thermometers that use a detection wavelength of 3 μm or less.

Selecting this model will allow users to measure workpiece temperatures through the glass.

OPTEX FA offers the BF series of special application thermometers that use a detection wavelength of 3 μm or less.

Selecting this model will allow users to measure workpiece temperatures through the glass.