01 Non-Contact Thermometer Selection Point 1:Wavelength.

Non-contact thermometers measure the infrared rays emitted by objects and convert the level of infrared rays into temperature.

Because non-contact thermometers vary according to the wavelength of the infrared rays they can receive, understanding the nature of wavelengths is necessary for selecting an appropriate model.

Because non-contact thermometers vary according to the wavelength of the infrared rays they can receive, understanding the nature of wavelengths is necessary for selecting an appropriate model.

The Nature of Wavelengths

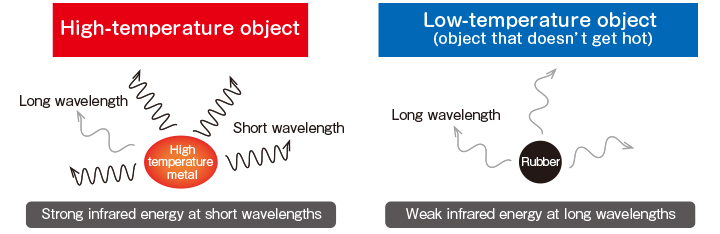

Every object emits infrared rays of different lengths (wavelengths).

However, depending on the temperature and material composition of the object, specific wavelengths may be emitted with greater or less strength.

However, depending on the temperature and material composition of the object, specific wavelengths may be emitted with greater or less strength.

Relationship between Object Temperature and Wavelength

For example, an object with a high temperature may emit strong infrared energy at short wavelengths, whereas an object with a low temperature hardly emits any infrared energy.

In this way, the infrared energy of the wavelength changes according to the temperature.

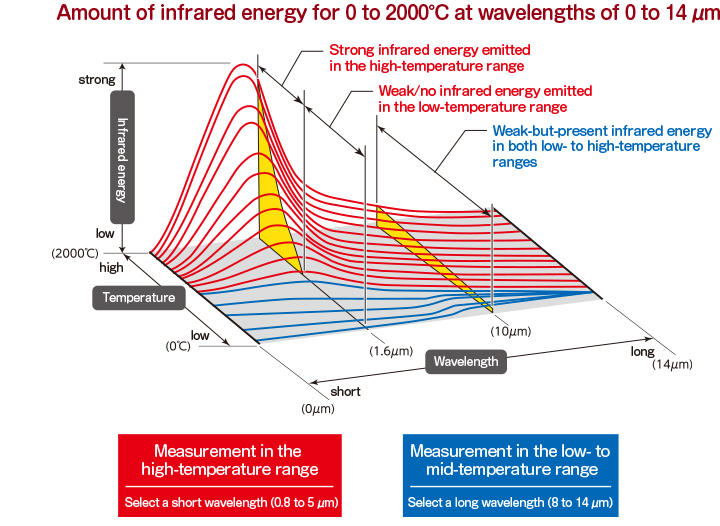

The following diagram details the relationship between temperature, wavelength, and infrared energy.

The following diagram details the relationship between temperature, wavelength, and infrared energy.

As the temperature increases, the infrared energy emitted at short wavelengths becomes stronger. As the temperature drops, the energy emitted becomes weaker.

Meanwhile, at longer wavelengths, the infrared energy emitted is consistently weak from low to high temperatures.

With this in mind, let’s look at differences in emissivity for each wavelength according to the actual material.

Meanwhile, at longer wavelengths, the infrared energy emitted is consistently weak from low to high temperatures.

With this in mind, let’s look at differences in emissivity for each wavelength according to the actual material.

Relationship between Object Material and Wavelength

Emissivity is the index that shows how much infrared energy is emitted at a specific wavelength.

An emissivity closer to 1 is easier to measure compared with an emissivity of 0, which will make temperature measurement impossible.

As such, emissivity is used to determine which wavelength is best for measurement when looking at the infrared rays emitted from an object.

In addition to emissivity, the reflection and transmission of the infrared rays are also important for determining wavelength selection.

These properties will be introduced in the next section.

The table below lists the emissivity of various materials and material conditions for wavelengths of 1.0 μm, 5.1 μm, and 8 to 14 μm.

An emissivity closer to 1 is easier to measure compared with an emissivity of 0, which will make temperature measurement impossible.

As such, emissivity is used to determine which wavelength is best for measurement when looking at the infrared rays emitted from an object.

In addition to emissivity, the reflection and transmission of the infrared rays are also important for determining wavelength selection.

These properties will be introduced in the next section.

The table below lists the emissivity of various materials and material conditions for wavelengths of 1.0 μm, 5.1 μm, and 8 to 14 μm.

| Emissivity | ||||

| Wavelength | 1.0μm | 5.1μm | 8 to 14μm | |

| Aluminum | Non-oxidized | 0.1 to 0.2 | 0.02 to 0.2 | 0.02 to 0.1 |

| Polished | 0.1 to 0.2 | 0.02 to 0.1 | 0.02 to 0.1 | |

| Rough | 0.2 to 0.8 | 0.1 to 0.4 | 0.1 to 0.3 | |

| Oxidized | 0.4 | 0.2 to 0.4 | 0.2 to 0.4 | |

| Iron | Non-oxidized | 0.34 | 0.05 to 0.25 | 0.05 to 0.2 |

| Rusted | 0.5 to 0.8 | 0.5 to 0.7 | ||

| Oxidized | 0.7 to 0.9 | 0.6 to 0.9 | 0.5 to 0.9 | |

| Casting/Purified | 0.9 | 0.9 | 0.9 | |

| Fused | 0.35 | |||

| Glass | Panel | 0.98 | 0.85 | |

| Fused | 0.9 | |||

| Rubber | 0.9 | 0.95 | ||

Shaded cells (  ) indicates an emissivity that is relatively higher than other wavelengths, making it suitable for measurement.

) indicates an emissivity that is relatively higher than other wavelengths, making it suitable for measurement.

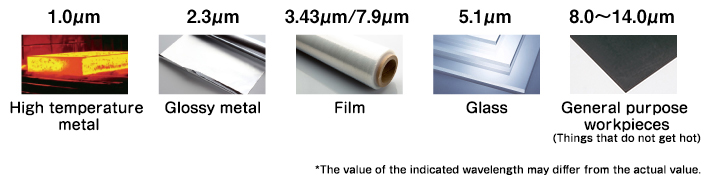

The wavelengths suitable for measurement for each material are included below.

) indicates an emissivity that is relatively higher than other wavelengths, making it suitable for measurement.

) indicates an emissivity that is relatively higher than other wavelengths, making it suitable for measurement. The wavelengths suitable for measurement for each material are included below.

Using the above as a reference, select a non-contact thermometer with a measurement wavelength suitable for the material to be analyzed.